So I didn't heed the advice I'd read online about knock off SSRs and decided to buy a Fotek SSR for my electric setup.

And on the second use I smelt an odd smell and thought I saw a wisp of smoke.

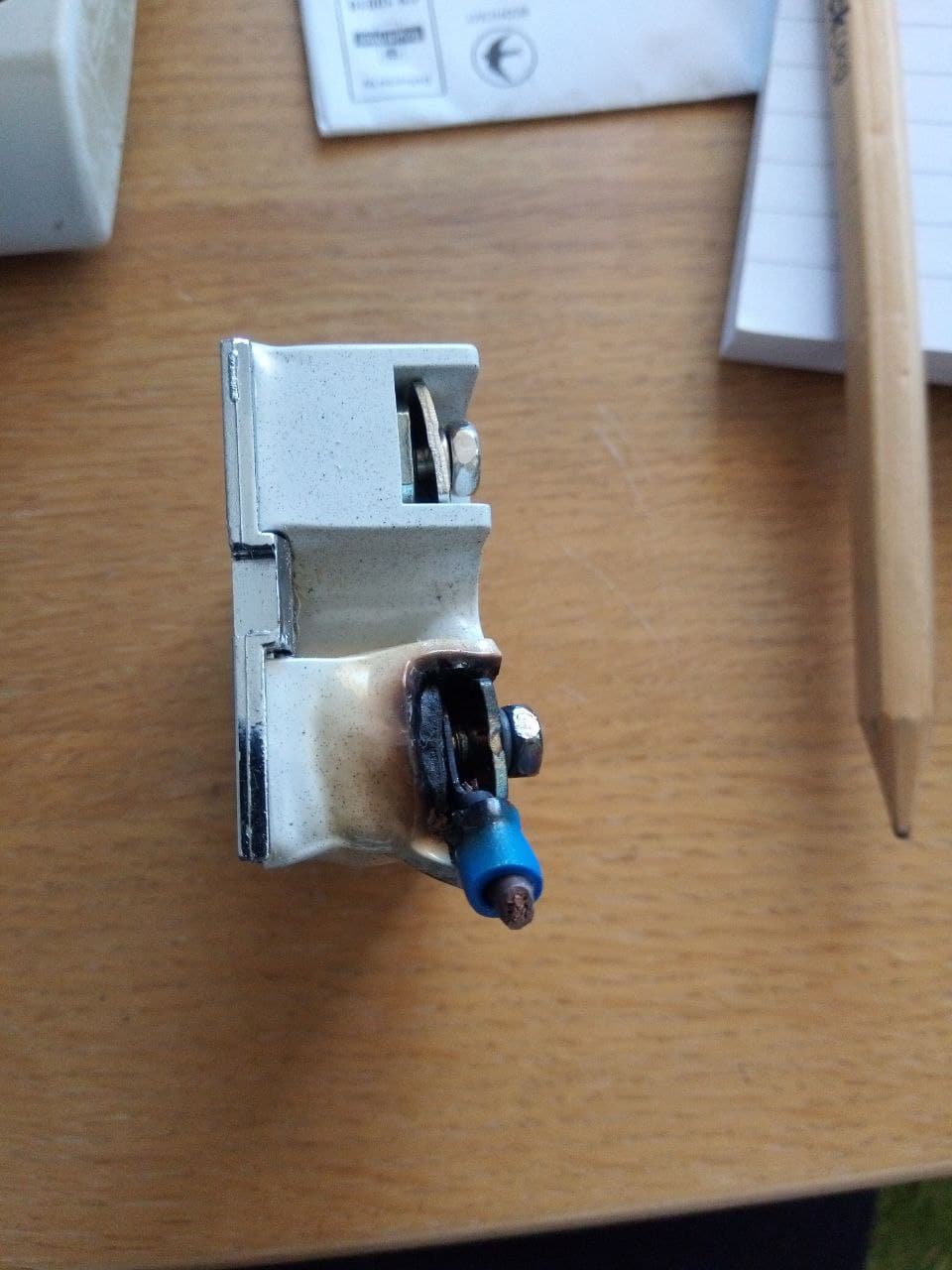

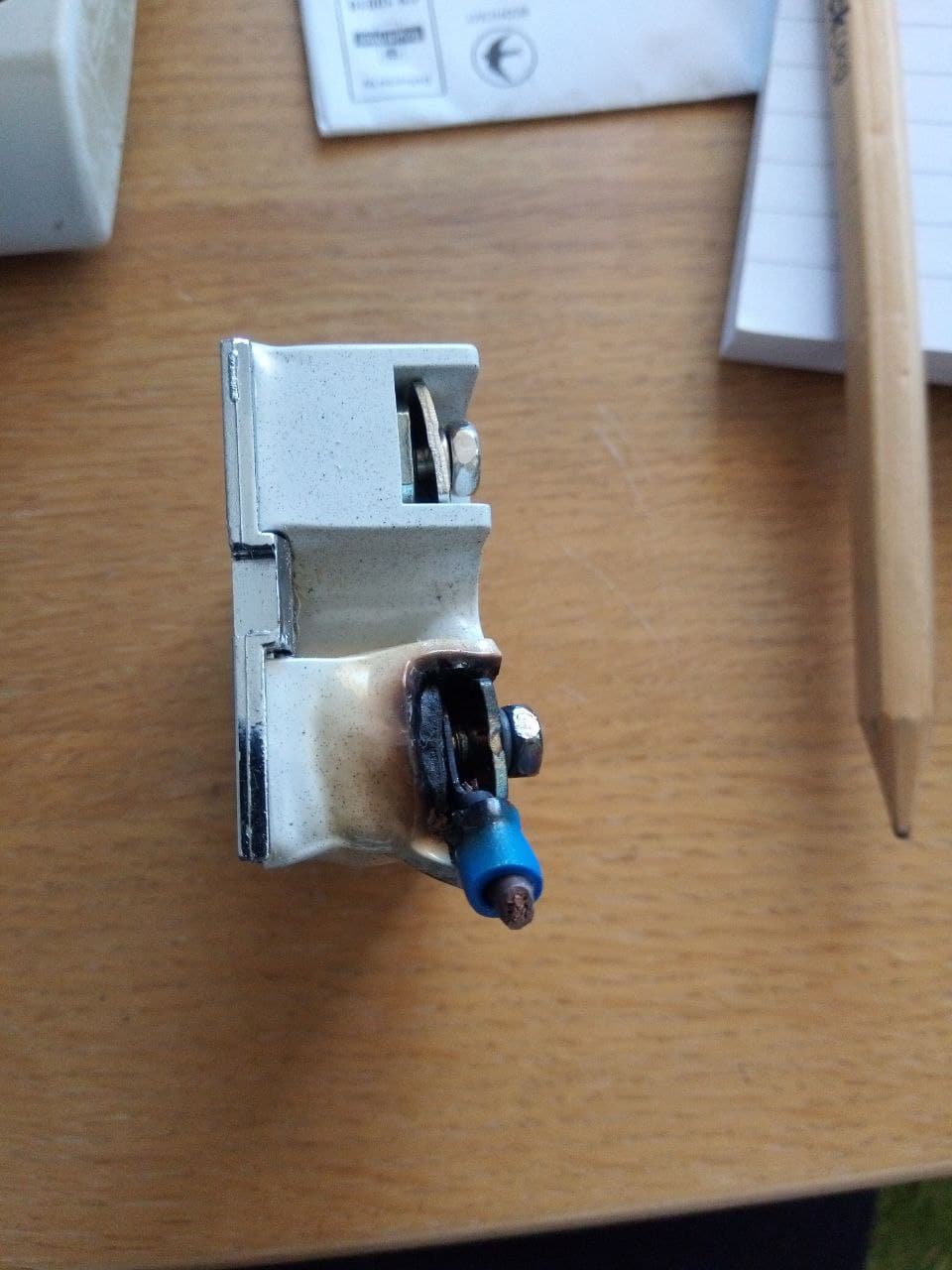

Sure enough when I took my controller apart, there was my SSR...

Also to note: this was rated for 40A and I only ever draw about 11 amps as I have a 2750 watt element.

And on the second use I smelt an odd smell and thought I saw a wisp of smoke.

Sure enough when I took my controller apart, there was my SSR...

Also to note: this was rated for 40A and I only ever draw about 11 amps as I have a 2750 watt element.