So long story short... I have been brewing with propane outside my town house garage once or twice a month for over a year and a half with no issues. I have spent a lot of time and money getting my all grain setup complete finally.. A dick neighbor called security on me in my community during my last brew day(probably thought i was making meth). They told be propane is not allowed in the community only NG and I would have to stop the propane burner use... Running a natural gas line and burners will still require a lot of ventilation, so I want to go the electric route. Soooo my fuse panel is also located in my garage. I am going to have a 220 outlet installed. It would also be nice to be able to brew in the garage over the winter with the door closed. .

My question is.,... I see some very cool but very pricy pre built controllers.. But none seem to fit my needs and I may have to build my own.. I currently have:

A keggle hlt. (sight glass, pickup tube, Drain valve, screw in thermometer)

A colman xtreme 70qt mash tun (3/4 inch ss braid screen)

A keggle boil kettle

A 2 tier brew stand

All the controllers seem to designed for MLT's with pump recirculation setups.

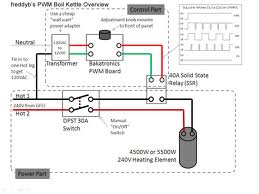

I just need a control unit to control 2 different - 5500w elements (not at the same time) I know i need 2 Pid's 2 SSR's and 2 temp sensors.. One for the HLT and One for the boil kettle. I would still like to mash in the cooler, as I have had no heat loss or efficiency issues. I also don't need the pumps as I have been just doing everything gravity fed..

I don't want to over complicate anything more than I need to.So my question is.....Has anyone here made a basic 2 PID, 2 ssr, 2outlet control box that could possibly help me out? I need no pump control wiring.. Just the ability to control and monitor temps on an HLT and Boil kettle. I'm new to the whole electric brewing scene and could use as much help as possible. I can do the wiring myself but will need help with a basic (idiot proof) schematic if possible.

I was going to go with 2 auberins SYL-2352. And 2 50amp SSr's and heatsinks.

Please any input , thoughts, advice, etc would be greatly appreciated..

My question is.,... I see some very cool but very pricy pre built controllers.. But none seem to fit my needs and I may have to build my own.. I currently have:

A keggle hlt. (sight glass, pickup tube, Drain valve, screw in thermometer)

A colman xtreme 70qt mash tun (3/4 inch ss braid screen)

A keggle boil kettle

A 2 tier brew stand

All the controllers seem to designed for MLT's with pump recirculation setups.

I just need a control unit to control 2 different - 5500w elements (not at the same time) I know i need 2 Pid's 2 SSR's and 2 temp sensors.. One for the HLT and One for the boil kettle. I would still like to mash in the cooler, as I have had no heat loss or efficiency issues. I also don't need the pumps as I have been just doing everything gravity fed..

I don't want to over complicate anything more than I need to.So my question is.....Has anyone here made a basic 2 PID, 2 ssr, 2outlet control box that could possibly help me out? I need no pump control wiring.. Just the ability to control and monitor temps on an HLT and Boil kettle. I'm new to the whole electric brewing scene and could use as much help as possible. I can do the wiring myself but will need help with a basic (idiot proof) schematic if possible.

I was going to go with 2 auberins SYL-2352. And 2 50amp SSr's and heatsinks.

Please any input , thoughts, advice, etc would be greatly appreciated..