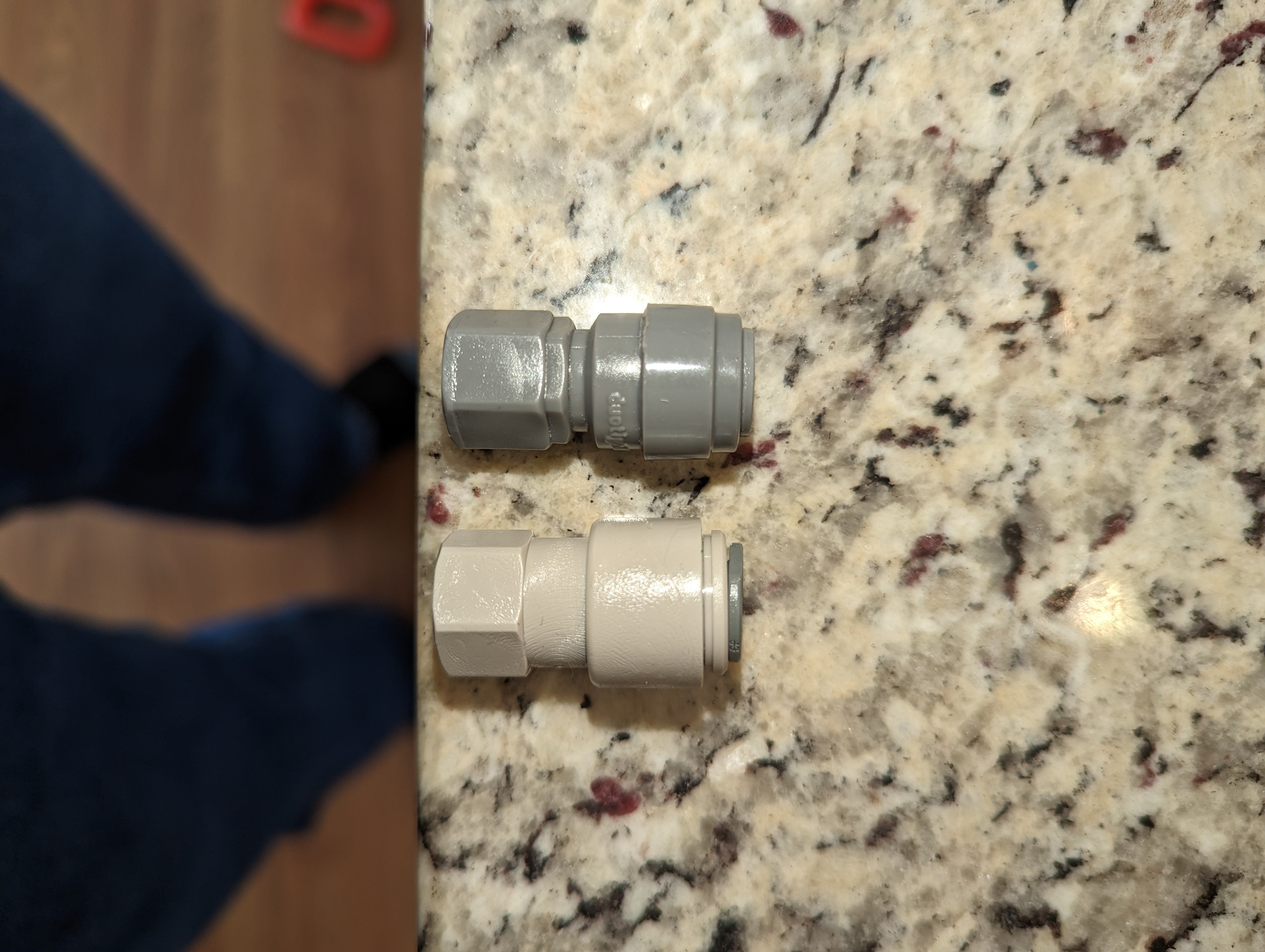

For plastic to metal fittings like this:

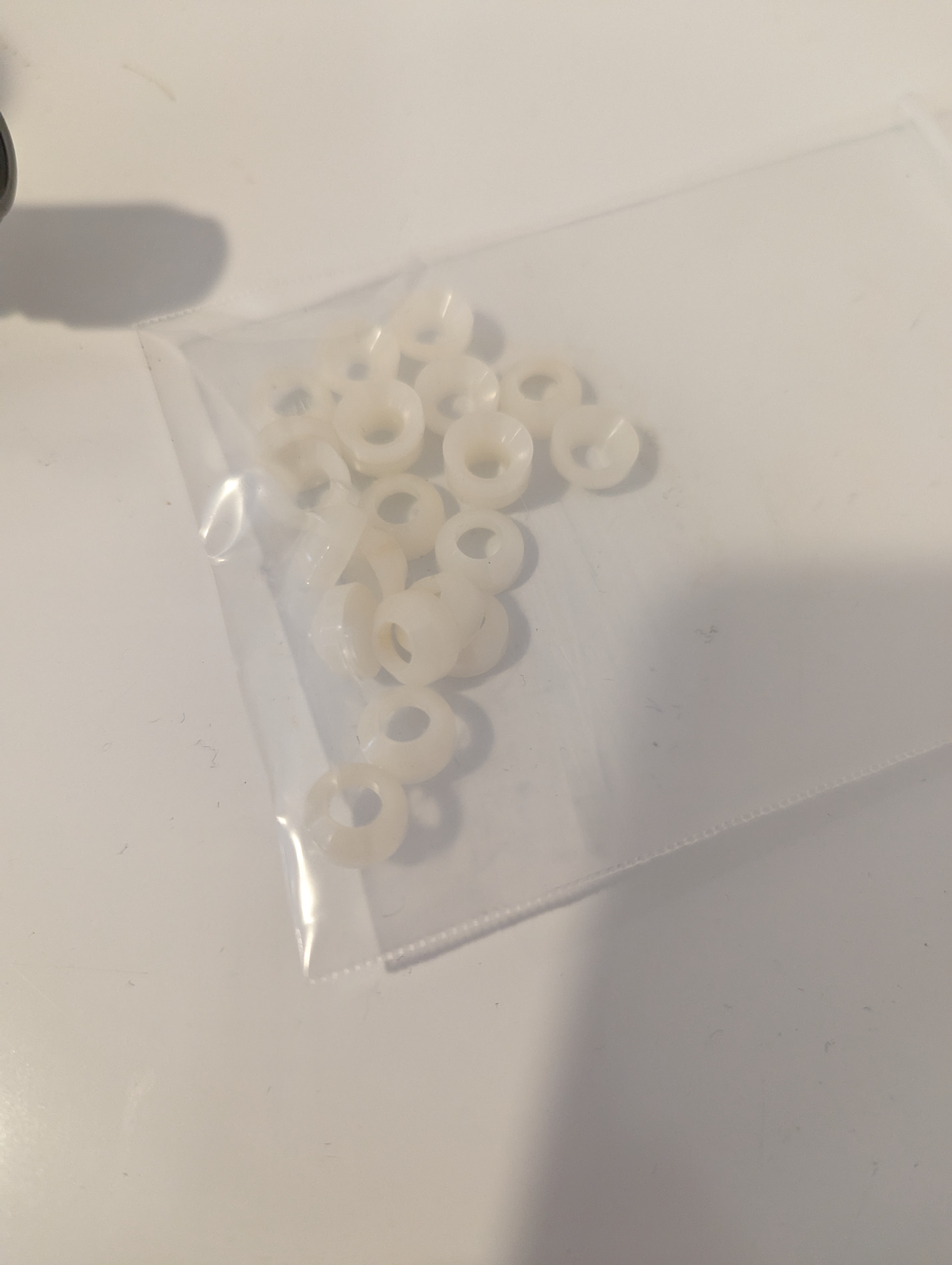

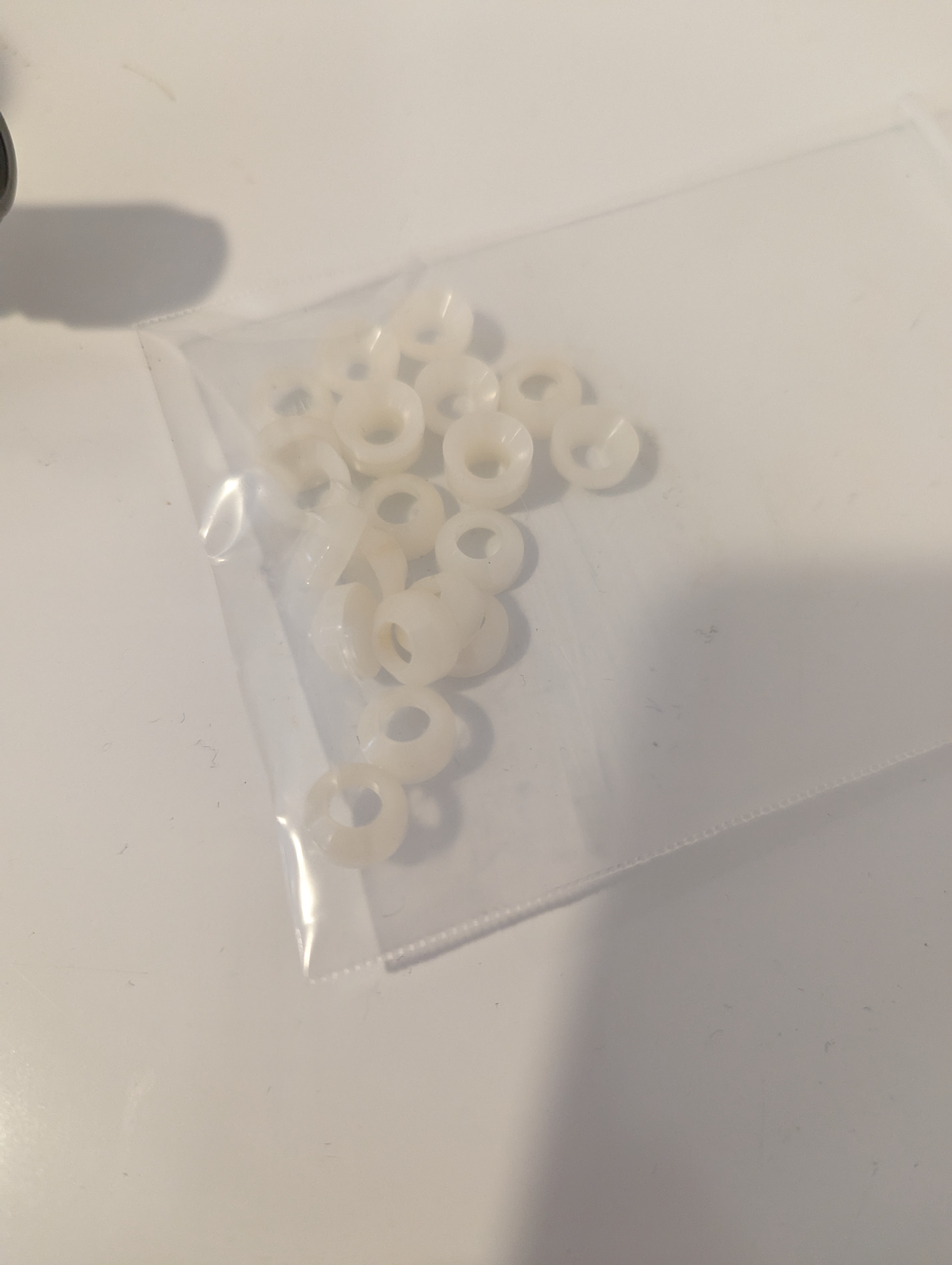

Should a plastic piece like so be inserted between:

I've read that they should or shouldn't be needed depending upon who you ask.

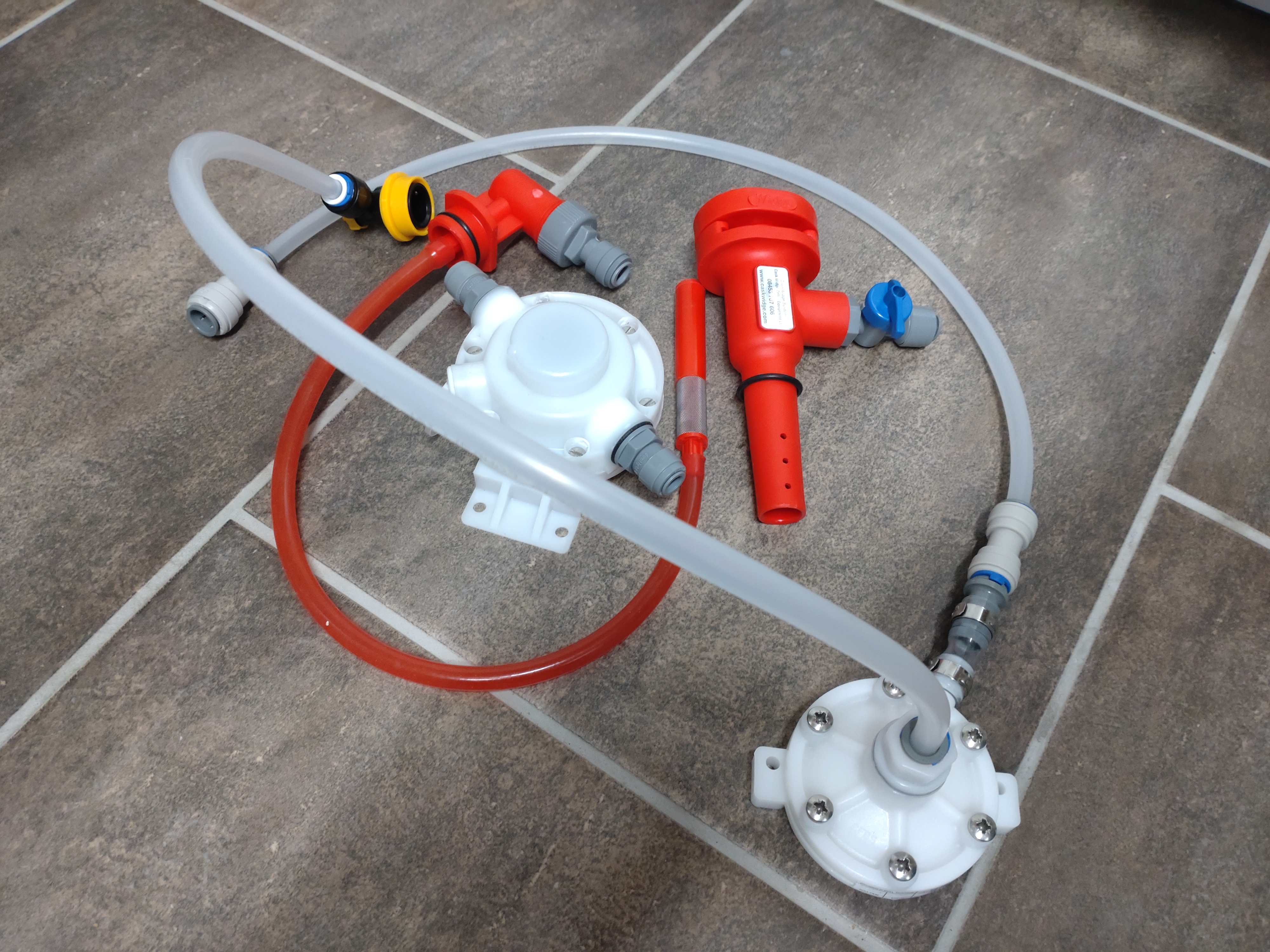

I realize with the ball lock taps they have a small rubber piece at the tip like so:

If going from a brass flare male end to a duo-tight female end there would be no such piece like that between them with adding a small plastic flare washer.

Also, does anyone have general advice on torque on these. Half past, quarter past hand tight, etc?

Should a plastic piece like so be inserted between:

I've read that they should or shouldn't be needed depending upon who you ask.

I realize with the ball lock taps they have a small rubber piece at the tip like so:

If going from a brass flare male end to a duo-tight female end there would be no such piece like that between them with adding a small plastic flare washer.

Also, does anyone have general advice on torque on these. Half past, quarter past hand tight, etc?