So I finally started my very own single tier brew rig and wanted to chronical it to get some feedback as I went through it.

Keggles

My keggles were welded by a friend who builds cryogenic systems for a living. A very impressive welder if I do say so. He also motivated me to try my hand at welding, so I bought a cheap welder on CL for $60.

Two of the three kegs welded. I ended up settling on four couplings on each keg.

-valve

-sight glass

-thermometer- I got 3 Ashcroft thermometers for $23 total. Killer Deal!

-recirculation

I even decided to try my hand at polishing a keg. The result is really cool, but it took about 3 hours. Still haven't decided if I'm going to do the other two.

All of my connections are stainless steel cam lock fittings from Pro Flow Dynamics.

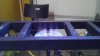

Rig

I am going to have 3 Banjo burners with two of them controlled by two Honeywell Y8610 kits. I do need some advice on how and where to mount the Y8610 modules. There will be a panel with all the switches to control the burners and pump that can be automated at a later date.

Here is the metal I picked up at the local scrap yard for $100. It is 2"x3" steel that is just over 1/16" thick. I know it is way overkill, but is was super cheap!

I got all of the metal cut with the help of a friend who let me borrow his chop saw.

Keggles

My keggles were welded by a friend who builds cryogenic systems for a living. A very impressive welder if I do say so. He also motivated me to try my hand at welding, so I bought a cheap welder on CL for $60.

Two of the three kegs welded. I ended up settling on four couplings on each keg.

-valve

-sight glass

-thermometer- I got 3 Ashcroft thermometers for $23 total. Killer Deal!

-recirculation

I even decided to try my hand at polishing a keg. The result is really cool, but it took about 3 hours. Still haven't decided if I'm going to do the other two.

All of my connections are stainless steel cam lock fittings from Pro Flow Dynamics.

Rig

I am going to have 3 Banjo burners with two of them controlled by two Honeywell Y8610 kits. I do need some advice on how and where to mount the Y8610 modules. There will be a panel with all the switches to control the burners and pump that can be automated at a later date.

Here is the metal I picked up at the local scrap yard for $100. It is 2"x3" steel that is just over 1/16" thick. I know it is way overkill, but is was super cheap!

I got all of the metal cut with the help of a friend who let me borrow his chop saw.