Ty520

Well-Known Member

- Joined

- Jul 21, 2020

- Messages

- 251

- Reaction score

- 150

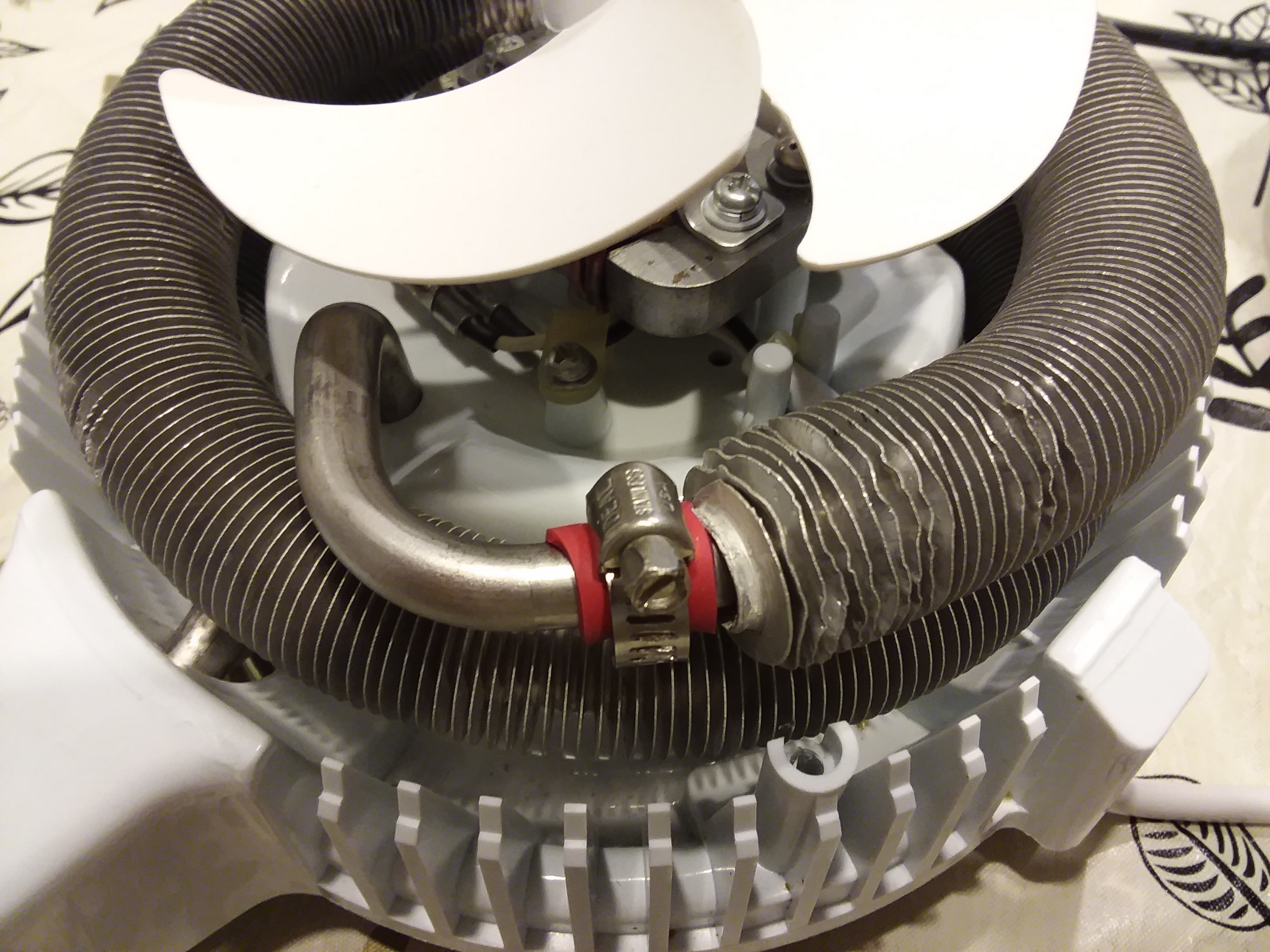

So I just bought an air still to experiment with distilling some of my wines and meads - I know it isn't an optimal rig, but it fits my budget, production and storage capacities for the time being; didn't want to sink a bunch of money into another hobby if it ends up going sideways. the good thing is that unlike some of the older air stills, it at least has control over the kettle temp.

After some talks with some more experienced distillers who have used an air still for micro experiments, I finally decided i needed to pull the trigger, fermented 1 gallon of cherry wine, and ran a stripping run. I was instructed to do it "fast and hot, and not make any cuts."

I began with the kettle set to 94*C (for note, i am at 2500 ft altitude). from the get-go, it emitted an unpleasant odor i can only describe as "fake butter." During research, this descriptor came up multiple times, so I wasn't completely worried.

Eventually, the flow began to slow down, and throughout the course of the run i gradually had to bump the temp up to maintain a flow of about 1 drip a second, finishing out at 98*C.

During the back end of distillation, though, it started to emit a smell I can only describe as "BBQ" - like that smell that lingers on your hands long after hitting up a BBQ joint

My assumption is that I ran it too hot? That being said, when I cleaned out the dregs, there was no signs of scorching/burning. so although it remains my lead hypothesis, I cannot be certain one way or another.

Another thought is that maybe it could have something to do with my wine base being composed of tart cherry, which is prefered in mead making...but perhaps too tart to maintain fresh, fruity aromas and flavors in a distillate?

After some talks with some more experienced distillers who have used an air still for micro experiments, I finally decided i needed to pull the trigger, fermented 1 gallon of cherry wine, and ran a stripping run. I was instructed to do it "fast and hot, and not make any cuts."

I began with the kettle set to 94*C (for note, i am at 2500 ft altitude). from the get-go, it emitted an unpleasant odor i can only describe as "fake butter." During research, this descriptor came up multiple times, so I wasn't completely worried.

Eventually, the flow began to slow down, and throughout the course of the run i gradually had to bump the temp up to maintain a flow of about 1 drip a second, finishing out at 98*C.

During the back end of distillation, though, it started to emit a smell I can only describe as "BBQ" - like that smell that lingers on your hands long after hitting up a BBQ joint

My assumption is that I ran it too hot? That being said, when I cleaned out the dregs, there was no signs of scorching/burning. so although it remains my lead hypothesis, I cannot be certain one way or another.

Another thought is that maybe it could have something to do with my wine base being composed of tart cherry, which is prefered in mead making...but perhaps too tart to maintain fresh, fruity aromas and flavors in a distillate?