There isn’t a ton out there on this forum regarding the catalyst system so I thought I would give a daily update on my first brew using it. Actually... first brew in about 4 years.

Details:

Honey Badger Amber (my own concoction)

Partial mash

2 lbs Vienna Malt

1 lb Caramel/Crystal 40L

1 lb Caramel/Crystal 75L

1 oz Willamette @ 60 minutes

3 lbs LDE @ 15 minutes

0.5 oz Willamette @ 10 minutes

0.5 oz Cascade @ 5 minutes

2 lb Honey (local farm) @ 5 minutes

0.5 oz Cascade @ 1 minute

0.5 oz Willamette @ 0 minutes

Safeale US-05

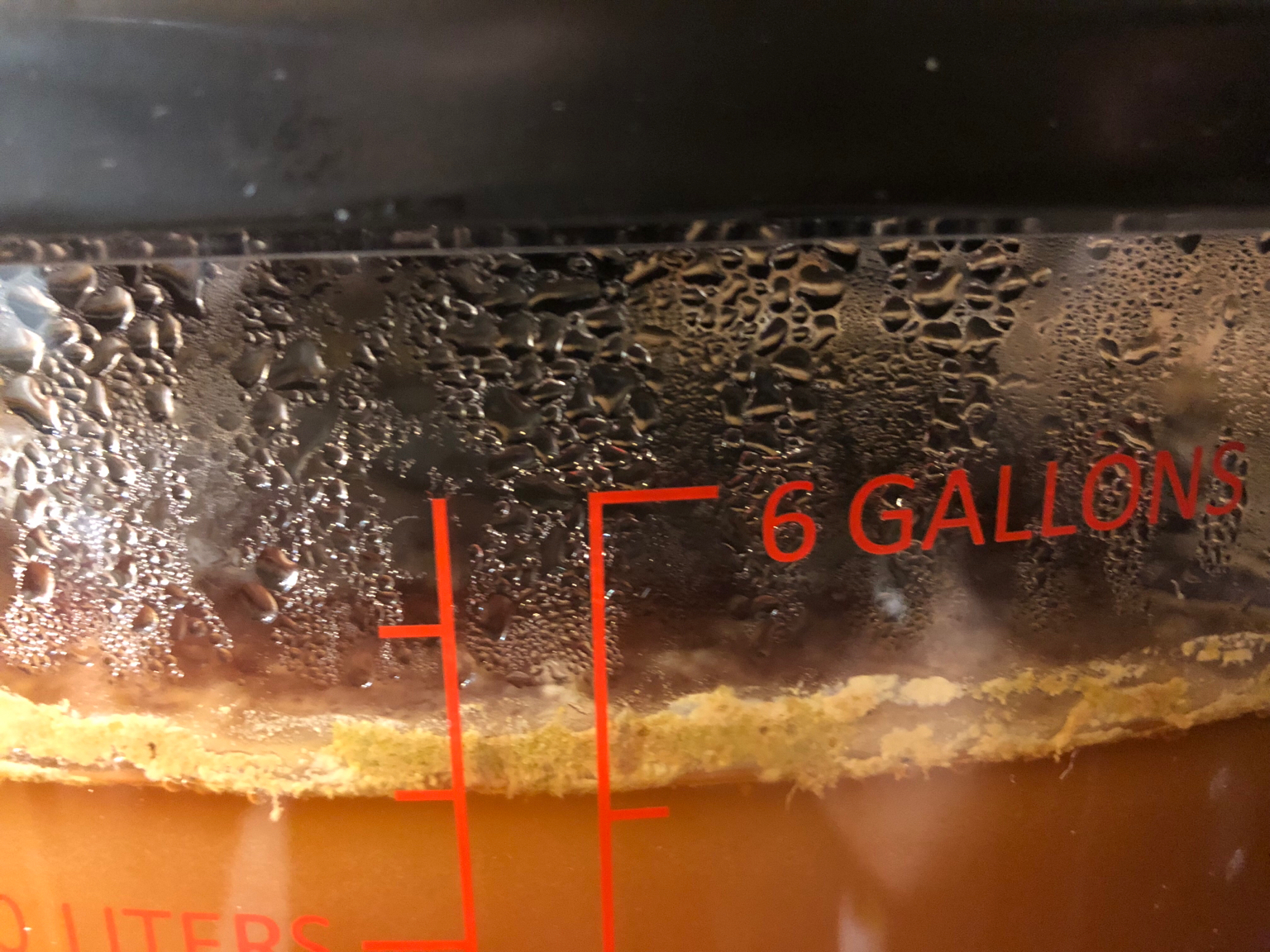

Added to the fermenter at 1.05 SG

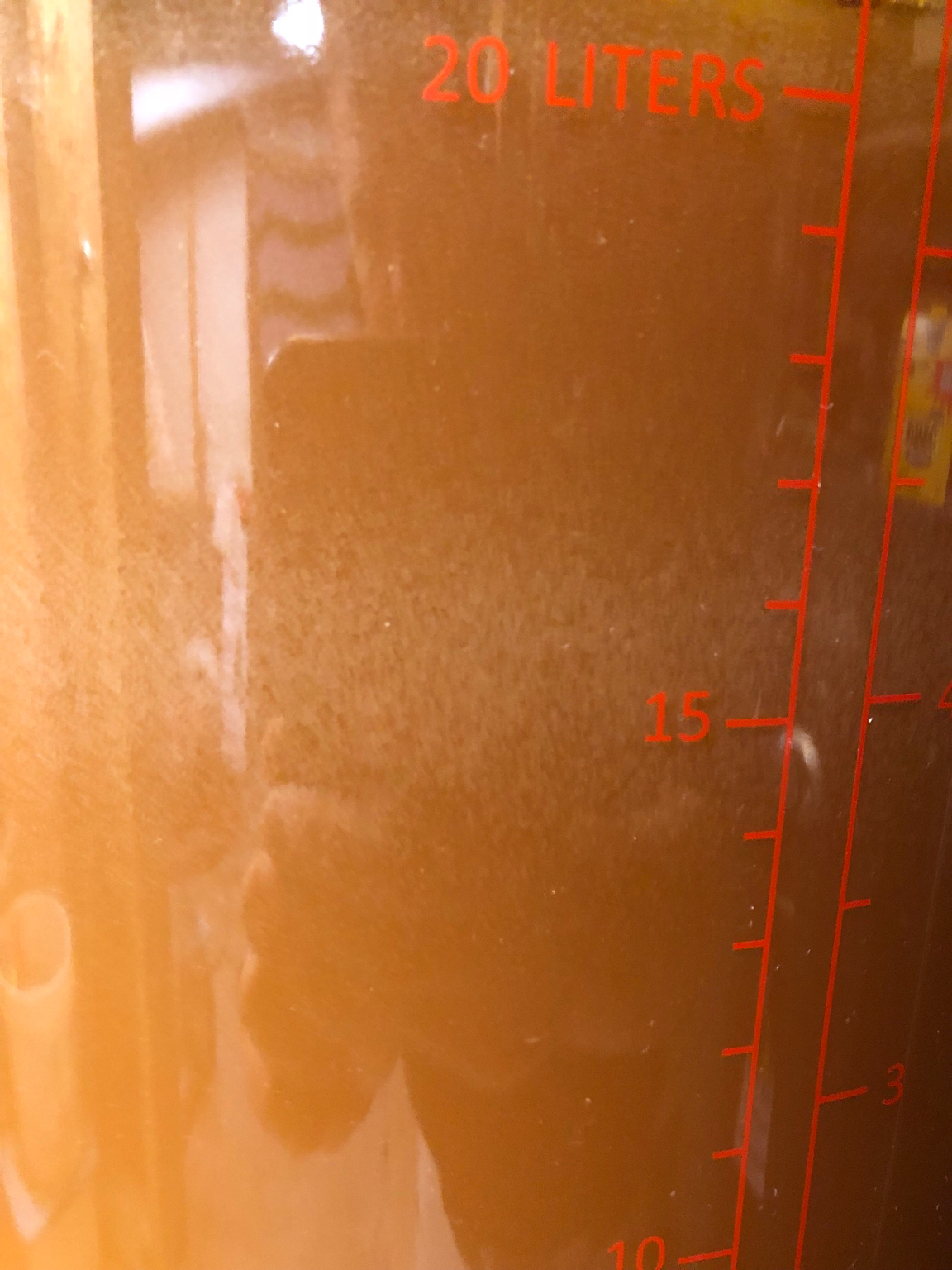

Day 0 (immediately following brew, yeast pitched in)

Details:

Honey Badger Amber (my own concoction)

Partial mash

2 lbs Vienna Malt

1 lb Caramel/Crystal 40L

1 lb Caramel/Crystal 75L

1 oz Willamette @ 60 minutes

3 lbs LDE @ 15 minutes

0.5 oz Willamette @ 10 minutes

0.5 oz Cascade @ 5 minutes

2 lb Honey (local farm) @ 5 minutes

0.5 oz Cascade @ 1 minute

0.5 oz Willamette @ 0 minutes

Safeale US-05

Added to the fermenter at 1.05 SG

Day 0 (immediately following brew, yeast pitched in)

Last edited: