Glad you got it going. Kurt also contributed and we had a nice discussion on GitHub about how to fix it. That's what makes this community strong!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fermentrack: Fermentation monitoring & BrewPi-www Replacement for Raspberry Pi

- Thread starter Thorrak

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'm getting closer. The output from DisplayLcd.cpp is reaching the Print_P function in IicLcd.h no problem but when Pilink calls for the display.getline(), the returned contents are garbled.

Any luck mrspin? I have similar issues, flashing a pre-compiled version everything is good, but I need to configure it for glycol. When I compile my own with the changes to the temp control values I need, my screen gets garbled, with a bunch of the characters that should be there on screen with some not shown.

I am using an LCD and that is garbled along with the virtual screen in Fermentrack.

Necropolis

Member

- Joined

- Jul 25, 2014

- Messages

- 17

- Reaction score

- 11

Not sure if this is the best place to post this, but:

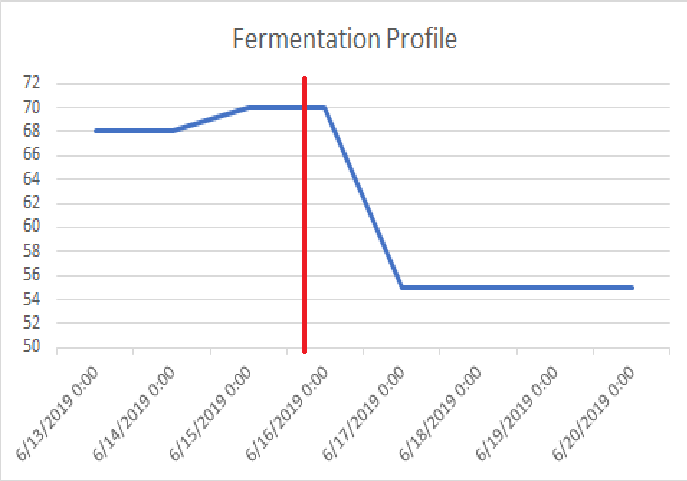

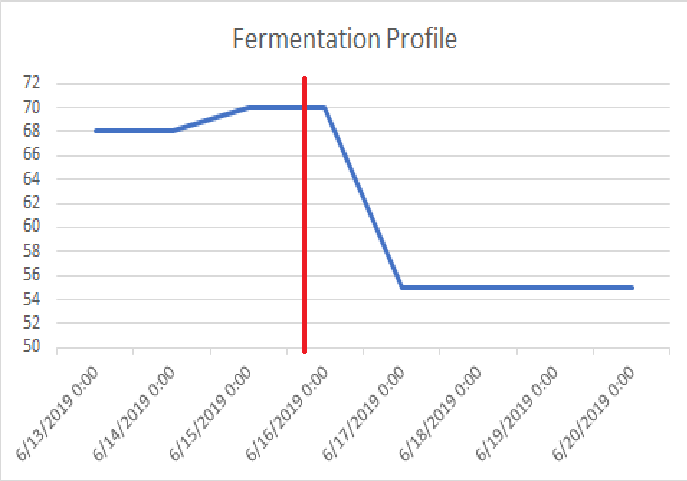

It would be cool to see where in the current profile a beer is - which set point.

It's pretty tricky to quickly figure that out as it stands.

It would be cool to see where in the current profile a beer is - which set point.

It's pretty tricky to quickly figure that out as it stands.

I’m just a spectator here but ... not quite following. You know the date and time and you can see the temp. What prevents you from making a logical connection to a temp step?

Necropolis

Member

- Joined

- Jul 25, 2014

- Messages

- 17

- Reaction score

- 11

You can - but there's no quick way to see what the profile is from the dashboard page - so if you don't remember how many set points your profile has you are a bit lost when looking at the dashboard.I’m just a spectator here but ... not quite following. You know the date and time and you can see the temp. What prevents you from making a logical connection to a temp step?

You can also switch profiles at any time and start them at any setpoint (without restating the logging) - if you do this then you have no idea where in the profile your beer is.

Ah, I got ya. I don't use that interface so I'm not familiar with the display. So if you had the chart and a representation of the current date/time would that be what you are after?

- Joined

- Nov 26, 2013

- Messages

- 7,843

- Reaction score

- 15,217

C'mon, man

Surely you can do better'n a dippy red line

A bouncing hop cone on the graph. That's what you want to do...

Surely you can do better'n a dippy red line

A bouncing hop cone on the graph. That's what you want to do...

Hey this isn't my project, I’m just the instigator.

PeteZA

Active Member

I have a little heater like the one your talking about. I have not hooked it up yet beceuse I too have a heating pad and was thinking of swapping it out. I did discover three safety features. 1) tip over switch: I removed this switch to bypass, the heater will be attached to a base it has no way of tipping. 2)Overheating switch: I did not remove this beceuse I figured if something were to go wrong the overheating circuit will shut off the entire unit. 3) time delay circuit: this one is tricky and I have not figured this one out yet. Its tied into the overheat circuit, basically the unit will not turn back on until the power switch is turned off then back on. This then switches on the time delay circuit. I have not timed the delay aspect but the user manual says 2 minute delay before the heater switches back on to protect the heating element from damage. I'm thinking of removing the time delay and run through the overheating circuit. What brand is the heater? I wonder if its similar to the one I have.

So at this stage my issue seems far more rudimentary. I'm a tad out of my depth here but fermentrack is showing it should be on a heating cycle. The heater is not on... When I measure the voltage at the relay it's showing 230v on both relays. I'd have assumed if it was firing the heater that it would show 230v but what's confusing AF is that it's also showing the same on the cooling relay. And just to be clear the fridge isn't on, so my assumption is that I am likely an idiot and measuring this all wrong...

- Joined

- Nov 26, 2013

- Messages

- 7,843

- Reaction score

- 15,217

Depends on what you measure.

A relay has two "bits", one is power that can or cannot be applied, and the other bit is switch, on or off. THe switch side is 5v and if it's off, then the power (230) side does not get turned on.

So measuring the power side will show that power is there, waiting to be used, but if the relay is "off" that power will not be passed through the relay to the heat/fridge. You need to measure the switching side to see if the switch is on or off.

A relay has two "bits", one is power that can or cannot be applied, and the other bit is switch, on or off. THe switch side is 5v and if it's off, then the power (230) side does not get turned on.

So measuring the power side will show that power is there, waiting to be used, but if the relay is "off" that power will not be passed through the relay to the heat/fridge. You need to measure the switching side to see if the switch is on or off.

PeteZA

Active Member

Awesome, thanks for that, between this, and earlier advice about just shorting IN2 and ground, I realised my problem was truly elementary... I had assigned the heater to the wrong pin... fkn idiot... But on the plus side, problem now solved!

matridium

Well-Known Member

- Joined

- Dec 5, 2018

- Messages

- 119

- Reaction score

- 30

Relays can be a pain if your new to the.. especially multiple pole relays. The kind used here are not too bad. Glad your figuring it out. Question I've had and have not had time to look it up. What does invert pin mean. Why and when should I invert the pin?Awesome, thanks for that, between this, and earlier advice about just shorting IN2 and ground, I realised my problem was truly elementary... I had assigned the heater to the wrong pin... fkn idiot... But on the plus side, problem now solved!

Not sure if this is the best place to post this, but:

It would be cool to see where in the current profile a beer is - which set point.

It's pretty tricky to quickly figure that out as it stands.

Makes sense. Let me figure out how, I'll get an issue opened to track against it.

EDIT - ...probably exactly as @LBussy recommended. If someone figures out how to do a hopping hop though...

I have been using fermentrack for a few beer now. I received and installed a Tilt Hydrometer. Since doing this the temperature axis now reads in 100 f intervals. Before installing the tilt my set interval was 5 F It is very difficult to pinch/expand on my phone to get a more precise reading. How can I set the standard interval to 5 f. Also is there a way to set the tilt intervals to .01 intervals?

I have been using fermentrack for a few beer now. I received and installed a Tilt Hydrometer. Since doing this the temperature axis now reads in 100 f intervals. Before installing the tilt my set interval was 5 F It is very difficult to pinch/expand on my phone to get a more precise reading. How can I set the standard interval to 5 f. Also is there a way to set the tilt intervals to .01 intervals?

You probably have outliers in your temperature data. Not much can be done at the moment to correct this, though you can click the icon in the legend to hide the temp data coming from the Tilt which might help.

The axis labels currently automatically set themselves based on your data. There isn’t currently an option to default them.

You probably have outliers in your temperature data. Not much can be done at the moment to correct this, though you can click the icon in the legend to hide the temp data coming from the Tilt which might help.

The axis labels currently automatically set themselves based on your data. There isn’t currently an option to default them.

Yes by taking out the gravity sensor temp from the graph it goes back to 10 degree intervals

Thanks for the temporary fix. Does this have something to do with the tilt. Can I reset the tilt or something to clear the outlier temp?

The problem is the outlier readings get stuck in the same array of persistent data that the graphing sources. One can run into the same paradigm in the original BrewPi when a ds18b20 probe read fails and returns "185°F". What would need to be done is to delete the corresponding record from the dataset so the scaling code doesn't see it. I've done as much in BrewPi as proof of concept but it's a totally manual edit-the-file thing...

Cheers!

Cheers!

There’s some statistical methods which could be applied to the numbers, either discarding outliers or smoothing via the various algorithms. Been playing with that a bit on Tilt. If I get it to work as I want in BrewPi I’ll submit a PR here with it.

Any luck mrspin? I have similar issues, flashing a pre-compiled version everything is good, but I need to configure it for glycol. When I compile my own with the changes to the temp control values I need, my screen gets garbled, with a bunch of the characters that should be there on screen with some not shown.

I am using an LCD and that is garbled along with the virtual screen in Fermentrack.

Yes - I had to comment out the LCD code to get it to work properly (I don't use an external LCD anyway). Something isn't right with the uploaded code vs. the binaries

Yes - I had to comment out the LCD code to get it to work properly (I don't use an external LCD anyway). Something isn't right with the uploaded code vs. the binaries

I can try that and see how it works from me... I use the screen so maybe I'll comment it out and if that works then dive into how that code works.

Anyone else know whats going on here?

Sunspots?

Stand

Well-Known Member

Swamp gas from a weather balloon.

matridium

Well-Known Member

- Joined

- Dec 5, 2018

- Messages

- 119

- Reaction score

- 30

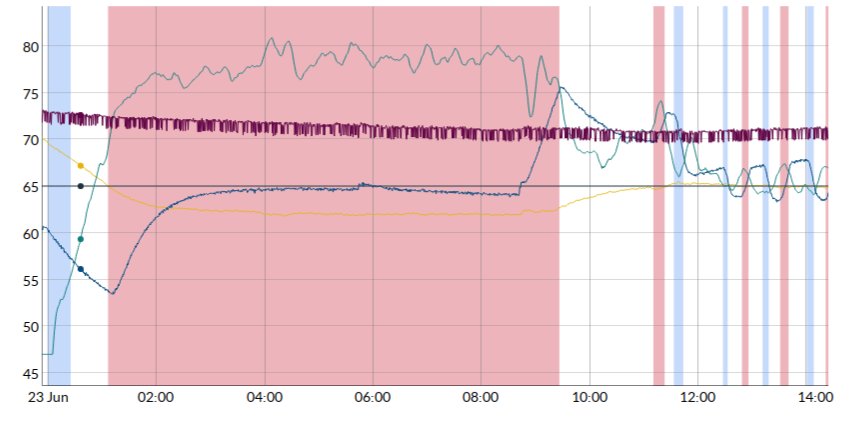

So I brewed a New England IPA last night and got it into the chamber and all setup with a brewing profile and started logging. It was not til this morning I noticed the fridge was plugged into the wall and not the chill side of the relay board. I'm impressed with how the software and control tried its hardest to maintain the beer constant. I set the beer to 65F and the beer was at 62.4... I pitched the yeast last night. This morning no fermentation I'm thinking the low temp slowed things way down. The yeast is safale so4.. its range is 53-73. Now what to do? Should I change over to beer constant temp and ramp up to 72f and hole it starts?

Nah, let it rise slowly to 65. It will go if the starter was good.

matridium

Well-Known Member

- Joined

- Dec 5, 2018

- Messages

- 119

- Reaction score

- 30

This IPA was a kit that came yeast in a pouch. I did not mKe a starter beceuse I'm just testing fermentrack out. So I wanted a quick kit and get testing. Hopefully it will take off.Nah, let it rise slowly to 65. It will go if the starter was good.

In that case nobody knows what will happen.

Is there any reason we should ever accept readings above, say, 101 deg C (i.e. - anyone see any reason not to auto-reject those data points?)

It’s a hamfisted solution, but those are the best kind.

@LBussy and I replied in the other thread

It’s a hamfisted solution, but those are the best kind.

my raspberry pi refuses to boot some kernal panic is there anyway to get my ispindle calibration point or fermentation logs before I reformatt sd card?

@LBussy and I replied in the other thread

matridium

Well-Known Member

- Joined

- Dec 5, 2018

- Messages

- 119

- Reaction score

- 30

So all is good the fermentation started about 18 hours after pitching. By the way the software tried really hard to get the beer to 65FIn that case nobody knows what will happen.

I don’t think so. The sensors fault at 85 though so are people using different sensors for sous vide?Is there any reason we should ever accept readings above, say, 101 deg C (i.e. - anyone see any reason not to auto-reject those data points?

If you do this in the script rather than firmware, you can allow user setting to clamp the readings. You could also apply a filter rather than a clamp (or both) to discarded those readings that are spurious.

The challenge with the filter is that a startup spike would not be caught. The question is: do people get these in the middle of a run for any reason? If so, filter. If not, clamp.

I don’t think so. The sensors fault at 85 though so are people using different sensors for sous vide?

The DS18B20 data sheet states

"Measures temperatures from -55°C to

+125°C. Fahrenheit equivalent is -67°F to

+257°F"

So I don't think the sensors themselves would have an issue with the higher temperatures.

Hrm ... I wonder why those are the "fault" temps that get sent then. Oh well, mystery solved.

Necropolis

Member

- Joined

- Jul 25, 2014

- Messages

- 17

- Reaction score

- 11

Makes sense. Let me figure out how, I'll get an issue opened to track against it.

EDIT - ...probably exactly as @LBussy recommended. If someone figures out how to do a hopping hop though...

Awesome - many thanks!

Hrm ... I wonder why those are the "fault" temps that get sent then. Oh well, mystery solved.

Quick google research shows that it shouldn't be powered parasitically at temperatures above 85°c. Maybe it's related.

Last edited:

afaik, none of the popular temperature controller/monitor packages support parasitic mode.

BrewPi didn't, and if BrewPiLess Fermentrack etc basically cloned the guts of BrewPi's firmware, they don't either...

Cheers!

BrewPi didn't, and if BrewPiLess Fermentrack etc basically cloned the guts of BrewPi's firmware, they don't either...

Cheers!

Thanks Trippr, I was strictly relating it to the error code lee referenced, not the software packages. But you do bring up a good point in that a sensor in parasitic mode won't even be recognized by a brewpi package.

My bad, I didn't mean to imply more than the lack of parasitic mode support.

fwiw, here's a very interesting line from the maxim ds18b20 spec:

"The power-on reset value of the temperature register is +85°C."

So, one might surmise compromised power might be where those false readings come from. Indeed, with all the screwing around I've done with ds18b20s on RPi's and Arduinos I can confirm if you eff with power while probes are being read a 185°F/85°C reading is likely to appear...

Cheers!

fwiw, here's a very interesting line from the maxim ds18b20 spec:

"The power-on reset value of the temperature register is +85°C."

So, one might surmise compromised power might be where those false readings come from. Indeed, with all the screwing around I've done with ds18b20s on RPi's and Arduinos I can confirm if you eff with power while probes are being read a 185°F/85°C reading is likely to appear...

Cheers!

matridium

Well-Known Member

- Joined

- Dec 5, 2018

- Messages

- 119

- Reaction score

- 30

Is there a way to append a profile while you using the profile and resume logging. I would like to modify a profile and keep logging the beer under the same file. I see there is pause logging if I pause and I edit the current profile? Will I have to load a new profile and start a new log?

CadiBrewer

Well-Known Member

Nope, the logging and the profile are independent of each other. You don't even need to pause the logging. Just create your profile and start it and the logging will document it all. You can even create a profile and start somewhere within the profile.

Stand

Well-Known Member

Is there a way to append a profile while you using the profile and resume logging. I would like to modify a profile and keep logging the beer under the same file. I see there is pause logging if I pause and I edit the current profile? Will I have to load a new profile and start a new log?

I literally just did this because I chilled my wort 2 degrees lower than I intended. Just set beer constant at current temperature and edit the profile. Restart profile when you've made the changes.

The log will keep going as CadiBrewer said, and it won't show any disruption to the logs. I've taken to making a Part 1 and Part 2 Profile because I'm going to temperature ramp and then cold crash based on FG rather than a set schedule.

I can't imagine NOT having this level of control anymore. It's ruined me.

Cheers!

Last edited:

Similar threads

- Replies

- 9

- Views

- 3K

- Replies

- 450

- Views

- 30K