NoNothing

Well-Known Member

I recently moved to TN and I don't have a basement. I miss my constant 65* MI basement wall for brewing.

Yeast are not liking fluctuating temps in the house from 70-75 in the summer and Im sure how cold we keep it in the winter cannot be great.

Solution? Fermentation chamber!

I typically will brew 2-3 beers at a time and make a day of it, so I need some space. Son of a fermentation chamber won't cut it.

Our garage is attached but non-heated. It goes from 90+ in the summer to around 40-50 in the winter. It has a window with a steel structure for an AC unit, and I happen to have a spare.

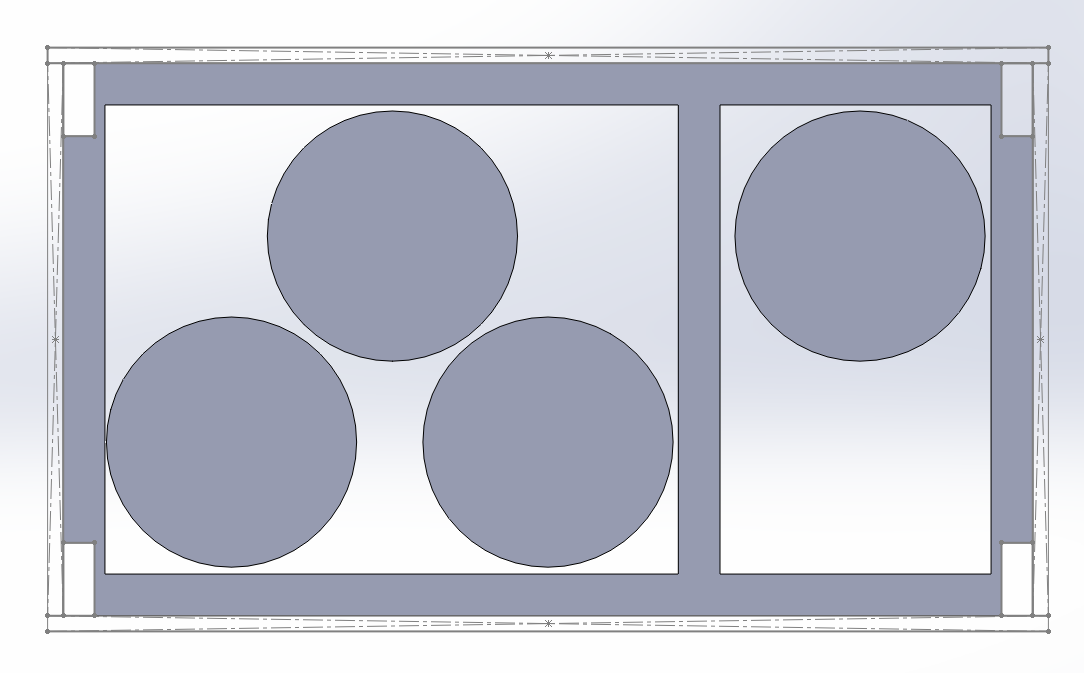

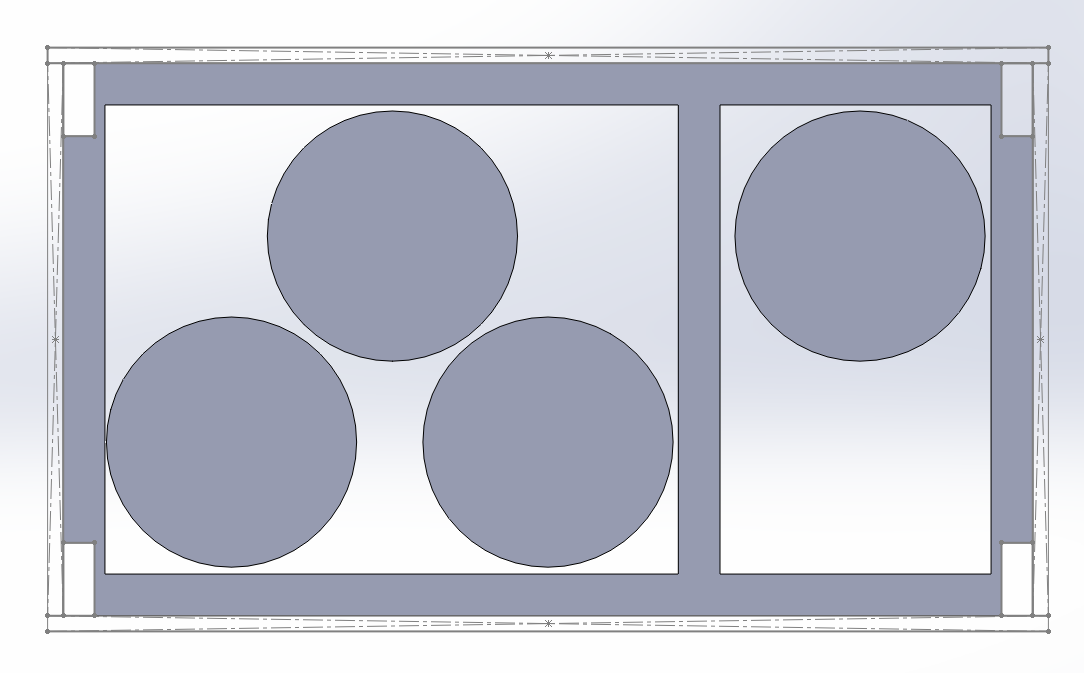

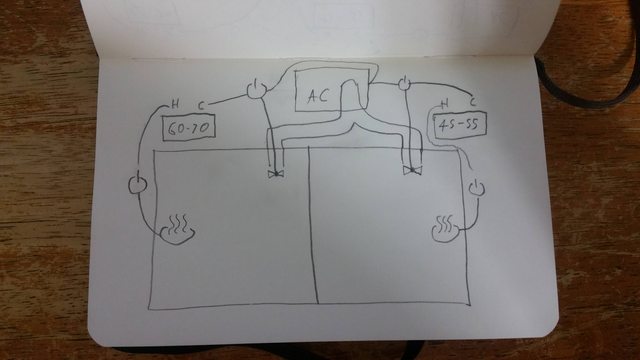

My plan is to build a 28x48" structure with 2" thick foam board insulating from the inside to ferment in. I've modeled it out and I can split it at 14" lengthwise to get 1 fermenter in one chamber and 3 in the other.

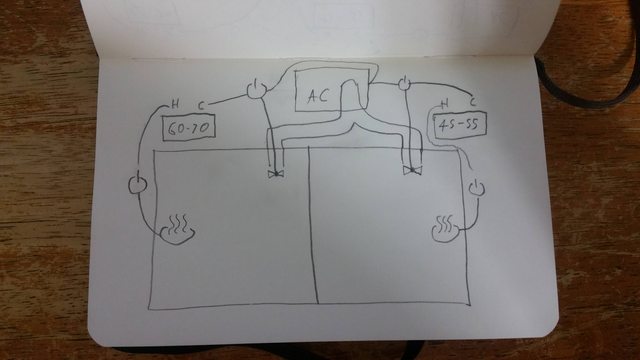

My question comes down to cooling. I plan on using a window AC unit for cooling with the thermostat bypassed and using a temp controller within the chamber itself. Might replace that with a fan and ambient air in the winter. Heat will be handled either by a pad, various keg wraps, or some reptile lamps. My plan is to have the smaller area be for lagering and the larger for ales.

If I cool directly into the lagering side with a fan exhausting into the ale side low on the wall and exhausting from ale -> lager side high will that be sufficient to keep 2 areas at different temps?

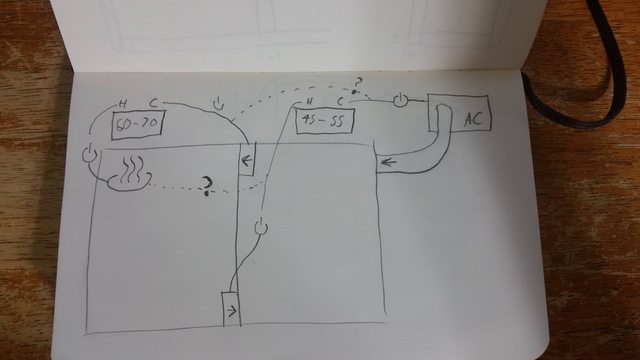

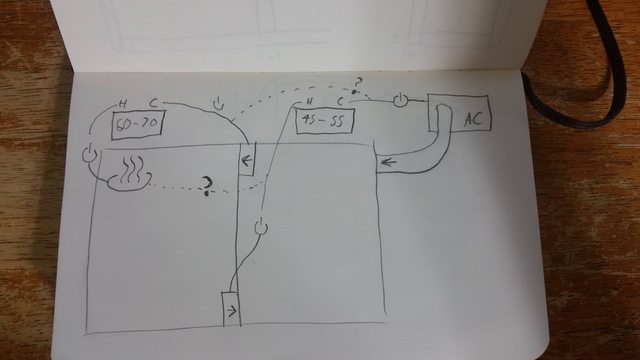

Another plan is to duct the AC separately into each chamber with a 12v relay and automotive door actuators or servo and arduino acting as control/relay opening a duct on each side so I can cool them individually or both. Both chambers would also have separate heat, no fans blowing between both of them. There's a LOT more involved in that. I already plan to 3D print the duct connection from the AC output to 3-4" PVC/ducting and then into the chamber. 3D printing some sort of duct that can be opened/closed is not impossible, but its a lot more moving parts and I'll certainly have some leakage. This version would have fans just to blow air around.

So my main question, is option 1, controlling with fans and having heat at one chamber and cool on another sufficient?

I know individual control is ideal, but then we're adding quite a bit more complication. Not to mention I need to figure out an actuated flap

Yeast are not liking fluctuating temps in the house from 70-75 in the summer and Im sure how cold we keep it in the winter cannot be great.

Solution? Fermentation chamber!

I typically will brew 2-3 beers at a time and make a day of it, so I need some space. Son of a fermentation chamber won't cut it.

Our garage is attached but non-heated. It goes from 90+ in the summer to around 40-50 in the winter. It has a window with a steel structure for an AC unit, and I happen to have a spare.

My plan is to build a 28x48" structure with 2" thick foam board insulating from the inside to ferment in. I've modeled it out and I can split it at 14" lengthwise to get 1 fermenter in one chamber and 3 in the other.

My question comes down to cooling. I plan on using a window AC unit for cooling with the thermostat bypassed and using a temp controller within the chamber itself. Might replace that with a fan and ambient air in the winter. Heat will be handled either by a pad, various keg wraps, or some reptile lamps. My plan is to have the smaller area be for lagering and the larger for ales.

If I cool directly into the lagering side with a fan exhausting into the ale side low on the wall and exhausting from ale -> lager side high will that be sufficient to keep 2 areas at different temps?

Another plan is to duct the AC separately into each chamber with a 12v relay and automotive door actuators or servo and arduino acting as control/relay opening a duct on each side so I can cool them individually or both. Both chambers would also have separate heat, no fans blowing between both of them. There's a LOT more involved in that. I already plan to 3D print the duct connection from the AC output to 3-4" PVC/ducting and then into the chamber. 3D printing some sort of duct that can be opened/closed is not impossible, but its a lot more moving parts and I'll certainly have some leakage. This version would have fans just to blow air around.

So my main question, is option 1, controlling with fans and having heat at one chamber and cool on another sufficient?

I know individual control is ideal, but then we're adding quite a bit more complication. Not to mention I need to figure out an actuated flap

Last edited by a moderator: