mneilson

Well-Known Member

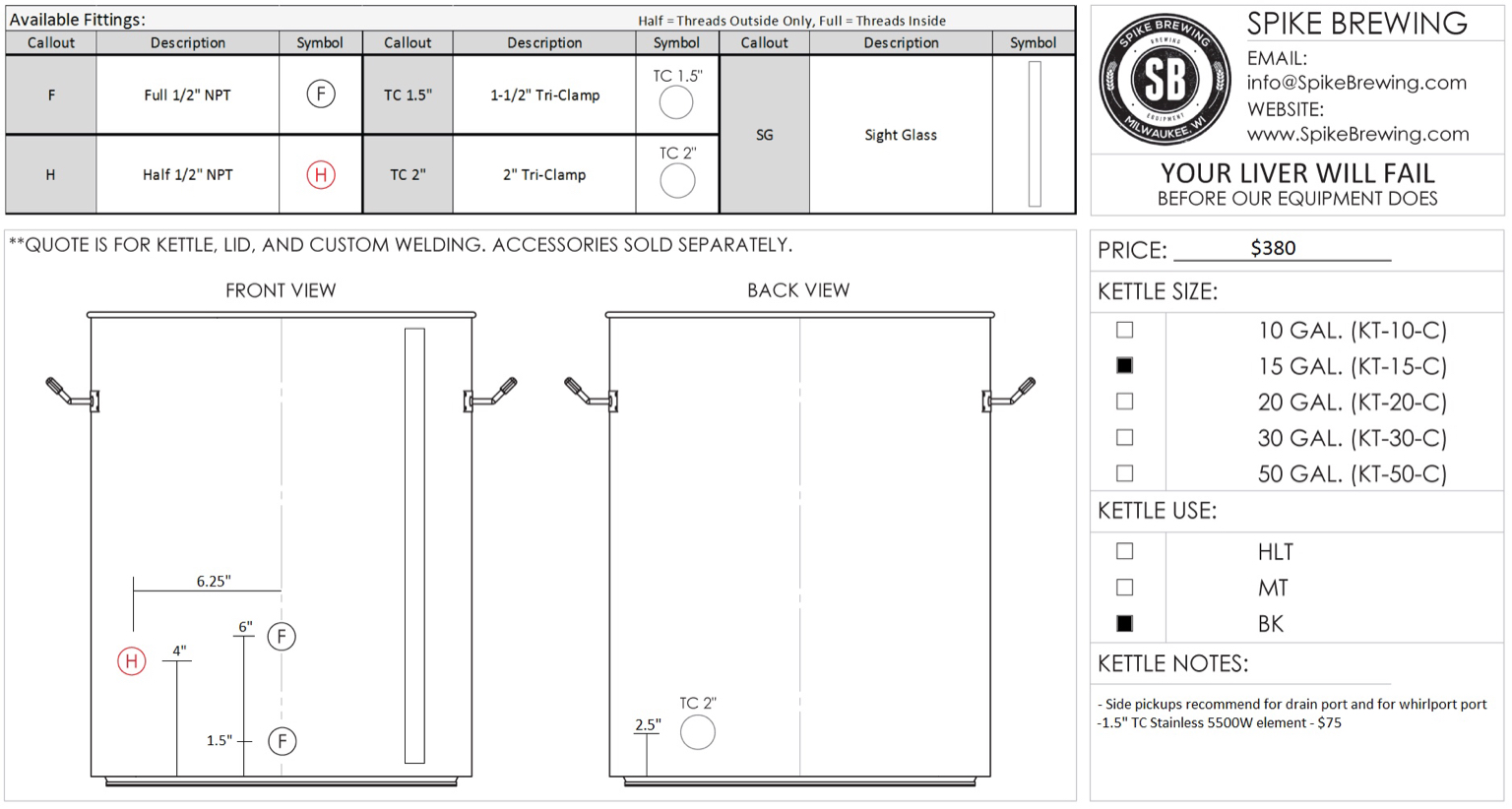

For the last year or so I've been debating about getting a new brew kettle (10 gallon, to be used for 2-6 gallon batch sizes either with single-vessel BIAB or cooler MIAB), and I have gone back and forth about remaining with a propane-fired kettle or moving to an electric system. I really like the idea of electric brewing (being able to schedule heating on a timer, lack of unsupervised flame, etc.), but I also like the portability associated with direct-fire kettles (e.g., homebrew club group brew events). Lately I've been wondering about if it's possible to have the best of both worlds: a kettle (e.g., one of the Spike 10 gallon) with a tri-clamp ferrule placed near the bottom to allow for both:

Does anyone have experience designing or using a dual-fuel system like this? Any drawbacks or complications that I'm not considering?

- direct fire (with a tri-clamp cap and high temperature silicone gasket on the ferrule), and

- electric (with a removable element housed in a tri-clamp enclosure; e.g., Brew Hardware Hot Pod).

Does anyone have experience designing or using a dual-fuel system like this? Any drawbacks or complications that I'm not considering?