Alteruser_404

New Member

- Joined

- Jun 16, 2020

- Messages

- 4

- Reaction score

- 0

Hello,

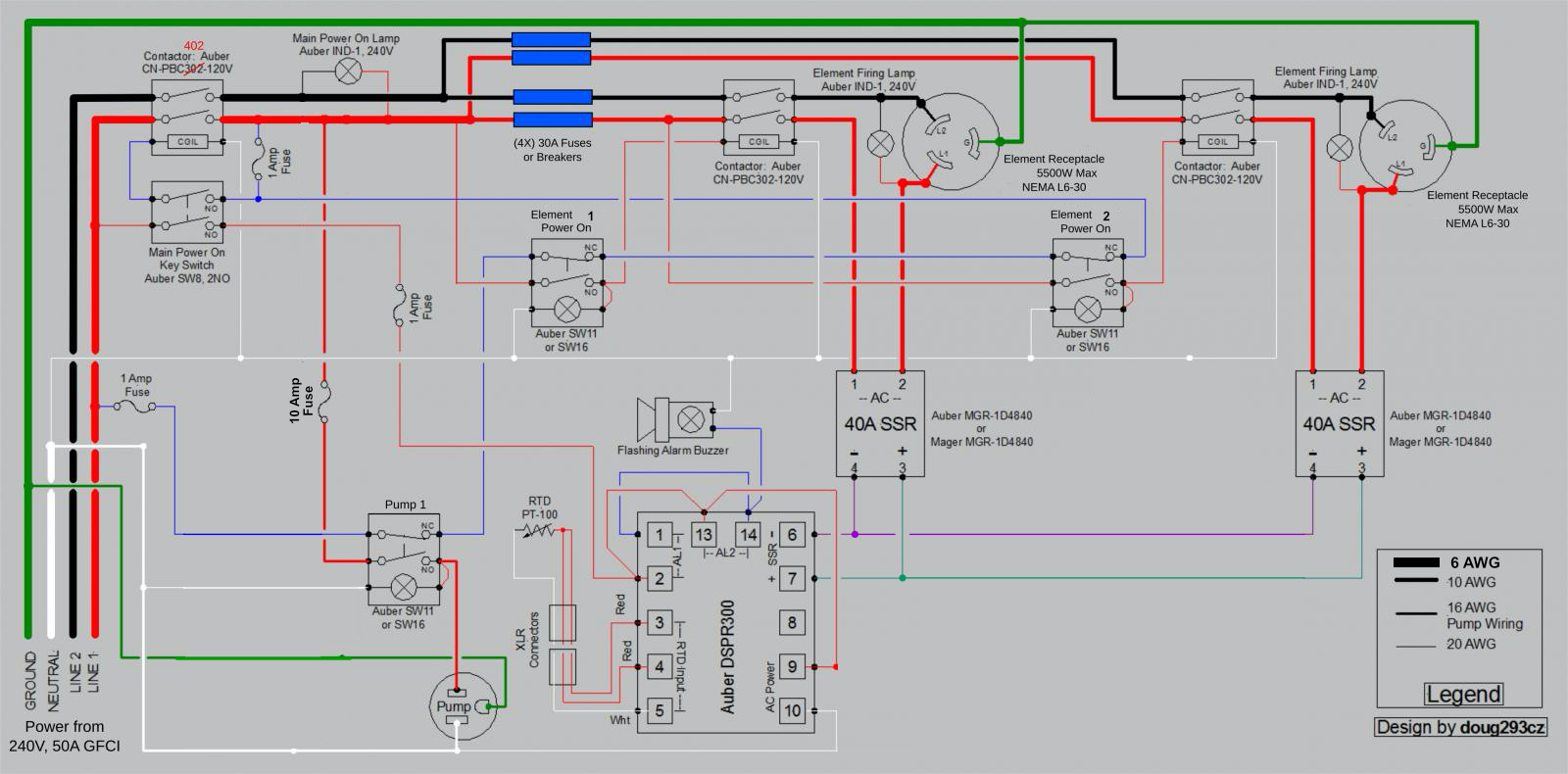

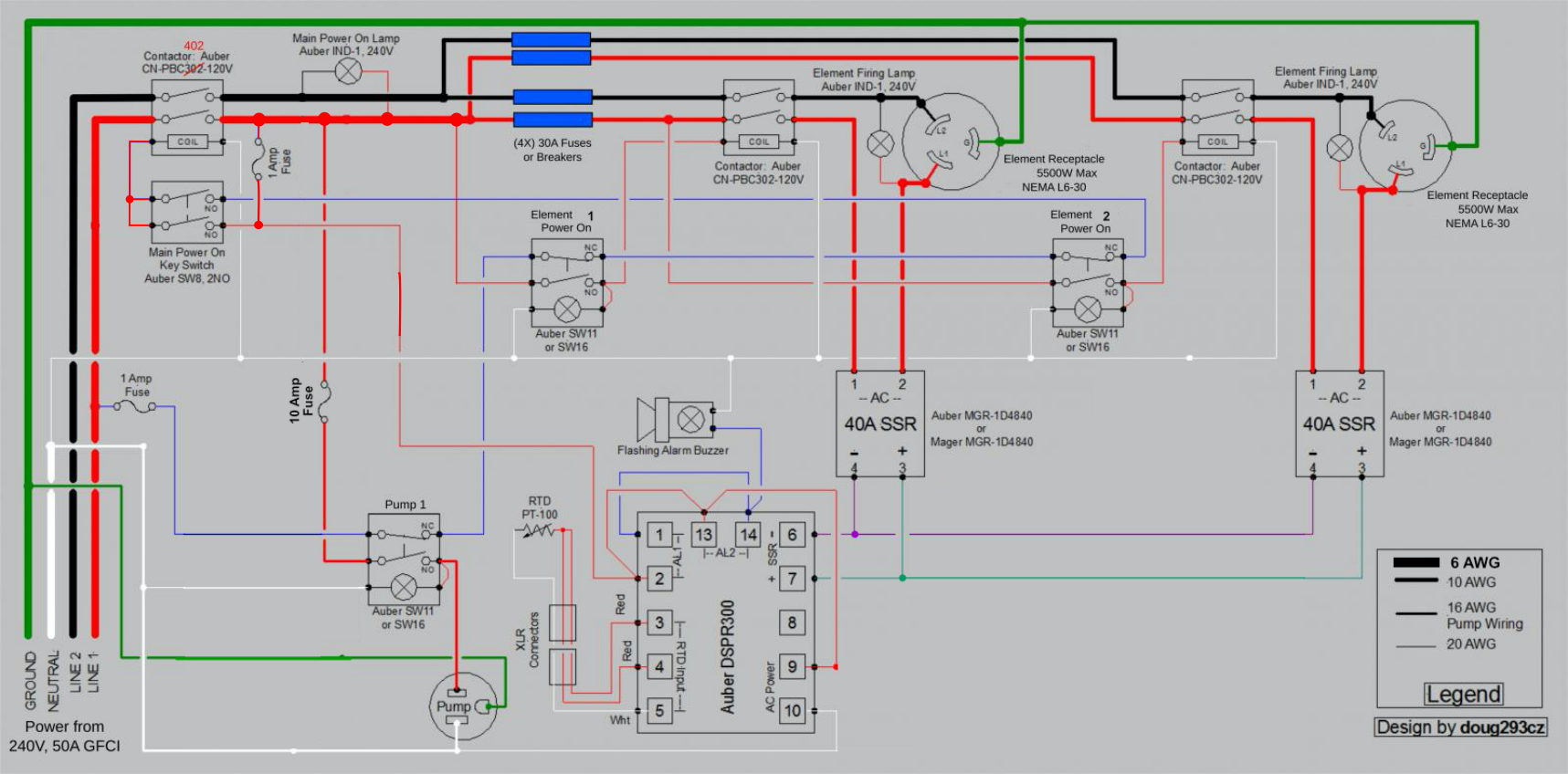

I'm trying to get a 1bbl system functional again as the controller that was purchased with the unit keeps killing elements and has caused enough trouble. after months of back and forth with the vendor of the system, we have had enough and are looking to just build our own unit. I've built some homebrew single element 240v PIDs but am struggling with the concept for 2 elements in one tank. The system is a BIAB style, so we don't need a mash tun or HLT to be heated, only 2 5500w 240v ripple elements. My original thought was to get 1 PID, 2 relays, and run two sets of sensor wires off the PID to the SSR, that way both of them would fire off the single PID and be controlled by one temp probe. This sounds a bit too easy so perhaps I am thinking it is more complicated than it needs to be. any help would be greatly apprecieted.

I'm trying to get a 1bbl system functional again as the controller that was purchased with the unit keeps killing elements and has caused enough trouble. after months of back and forth with the vendor of the system, we have had enough and are looking to just build our own unit. I've built some homebrew single element 240v PIDs but am struggling with the concept for 2 elements in one tank. The system is a BIAB style, so we don't need a mash tun or HLT to be heated, only 2 5500w 240v ripple elements. My original thought was to get 1 PID, 2 relays, and run two sets of sensor wires off the PID to the SSR, that way both of them would fire off the single PID and be controlled by one temp probe. This sounds a bit too easy so perhaps I am thinking it is more complicated than it needs to be. any help would be greatly apprecieted.