I bought one of Yuri's conicals and months ago, but by the time i was set up to use it, summer had hit and the basement just wasn't cool enough. so we did a 100% rye mash, which has been turned into some wonderful whiskey.

We had some left after the run-off, and i was waiting until the weather cooled down to brew some beer in there. So we went to open it up the other day, expecting some foulness to clean up inside. Pop the lid, and there was still co2 in there! it smelled great, a little sour, but great. We took a sample, and it tasted like a lambic!

So my friend brought over some black berries and a lambic yeast blend (brett and lacto, i think). We'll blend with another wort later and make a gueuze/kriek type thing. After it's bottled, i'm going to destroy all the equipment we use as i'm not a big fan of brett

but i'm really curious as to how this turns out.

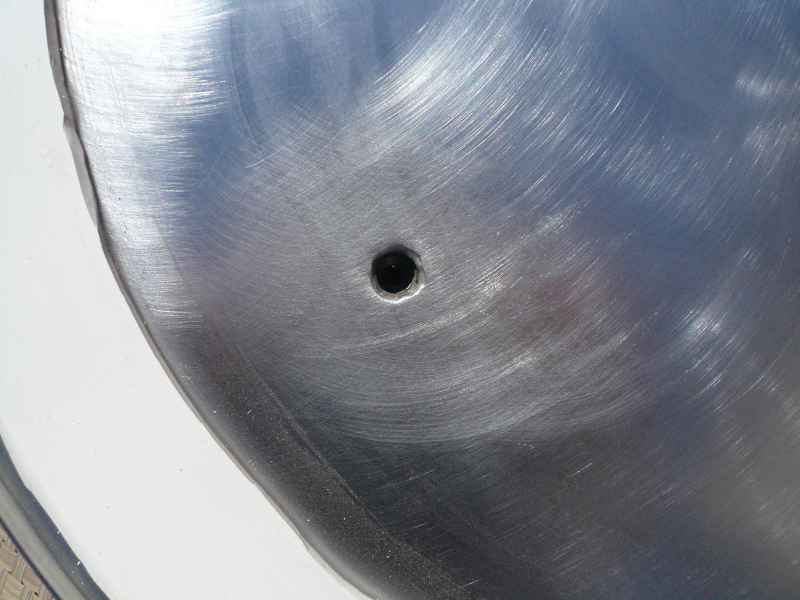

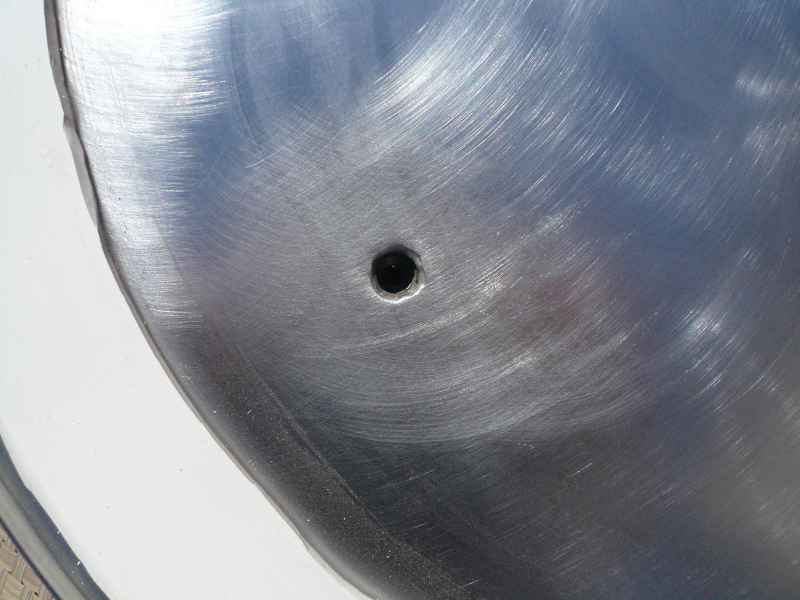

anyway, we dismantled and cleaned the conical out and, now that the weather is cool again, we brewed up my first 15 gallon batch of beer yesterday. i made my SMaSH Ale:

30 lbs of Vienna Malt (150°F mash)

2.5 oz 7% Northern Brewer @ 60 min

2.0 oz 7% Northern Brewer @ 20 min

2.0 oz 7% Northern Brewer @ Flameout

3 packs nottingham yeast

i ended up getting 90% efficiency! there was very little heat loss in the mash (we completely filled a 15.5 gallon keg) and the rest of the session went incredibly smooth. it only took us 6 hours compared to our regular 5 for 5 gallons. big batches are the way to go! We're going to do a batch every 2-3 weeks with this and keep kegs constantly full of tried and true recipes.

Yuri, thanks again! wonderful setup!