SilverZero

Well-Known Member

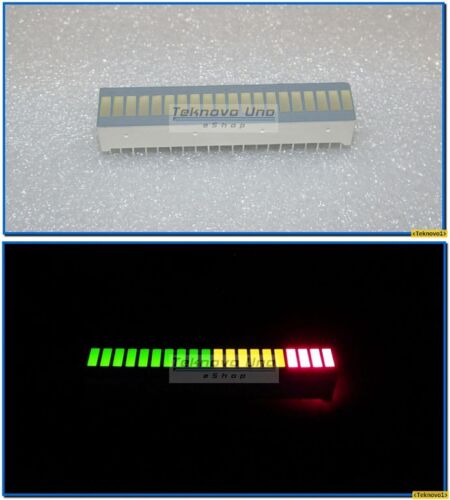

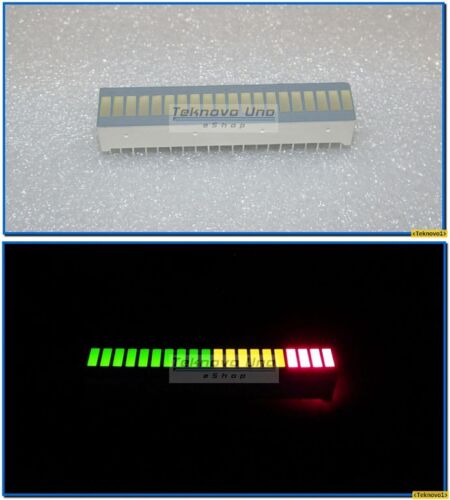

Hey all, I'm starting my control panel build and I'm incorporating an analog potentiometer-based PWM (LED dimmer from eBay with some mods to slow the pulse rate to about 1Hz) for the boil kettle. I'd like to add some sort of display to show the potentiometer position.

I was thinking of using an LED VU meter, but I'm not sure if I'd have to interface them via an Arduino and the analogRead function or what. I'm a beginner when it comes to programming but I could figure it out with the right keywords to Google. Or is there a more direct way to measure the potentiometer output?

I had also considered displaying on a two-digit 7-segment LED display but I couldn't find any displays like that, but if I could I'm sure I could use analogReadSerial and then output the 0-1023 values in increments from 0 to 11 (because of course it would go to 11).

I was thinking of using an LED VU meter, but I'm not sure if I'd have to interface them via an Arduino and the analogRead function or what. I'm a beginner when it comes to programming but I could figure it out with the right keywords to Google. Or is there a more direct way to measure the potentiometer output?

I had also considered displaying on a two-digit 7-segment LED display but I couldn't find any displays like that, but if I could I'm sure I could use analogReadSerial and then output the 0-1023 values in increments from 0 to 11 (because of course it would go to 11).

:rockin:

:rockin: