specialkayme

Well-Known Member

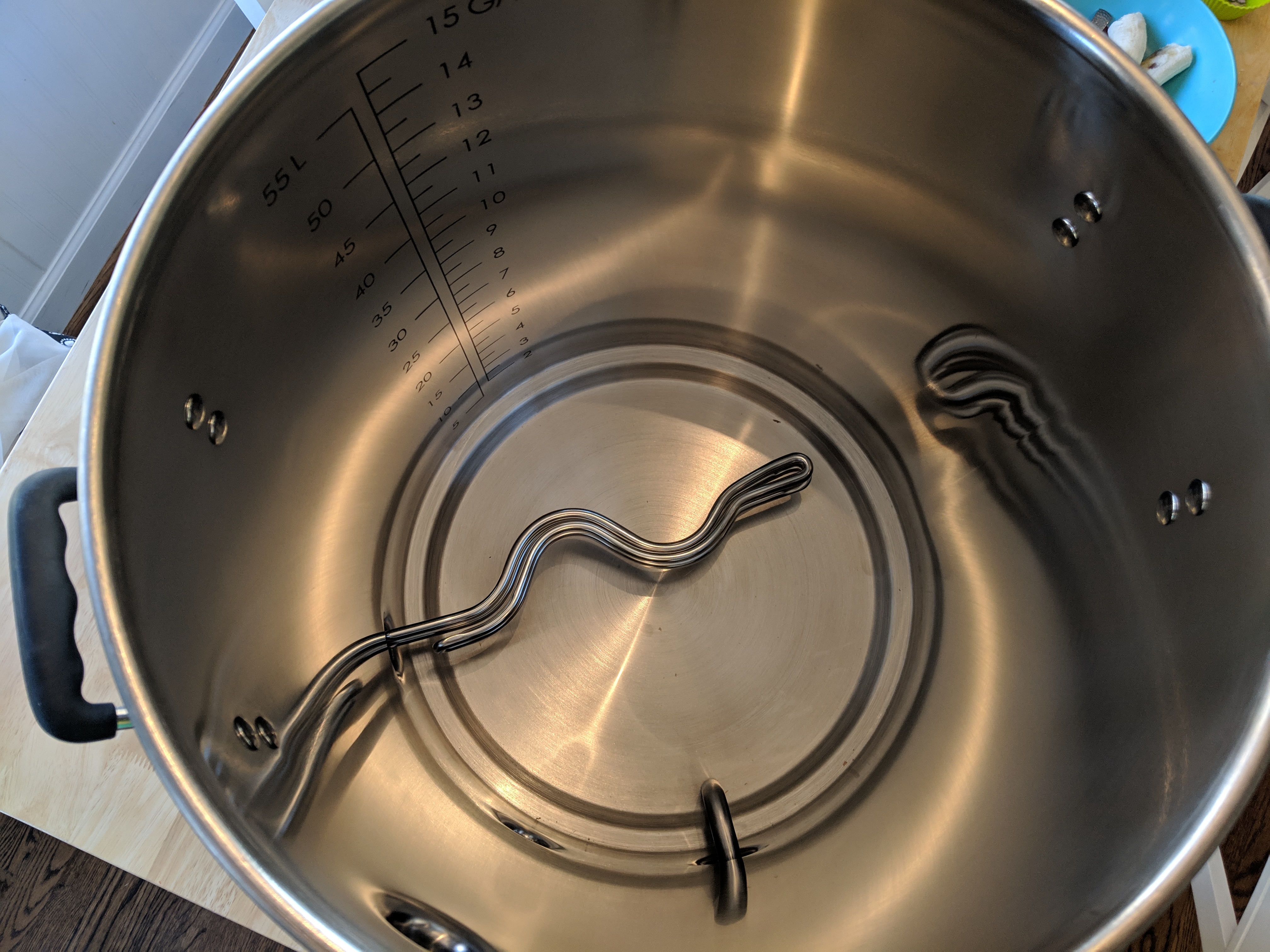

After much pondering, I think I'm going to order a custom Spike kettle in order to turn it into a one vessel eBIAB system. I've never had, or used a kettle with ports on it (I've always just used standard kitchen pots), so I was hoping I could get some insight and help on designing the kettle.

My design is to use the kettle as both the mash tun and the kettle with an electronic heating element. I have no plans to go fully automated, or use a temp controller, or a HERMS or similar system. I was hoping to do no sparge batches moving forward. So I was considering going with a 15 gal kettle size, in order to allow me to do full volume no sparge, high gravity batches. I assumed a 10 gallon kettle, with 7.5 gallons of water (for the odd 90 min boil) and 15 lbs of grain won't go over too well space wise. So the 15 gallon kettle will give me a little more flexibility (even though I realistically speaking don't ever plan on doing 10 gallon batches).

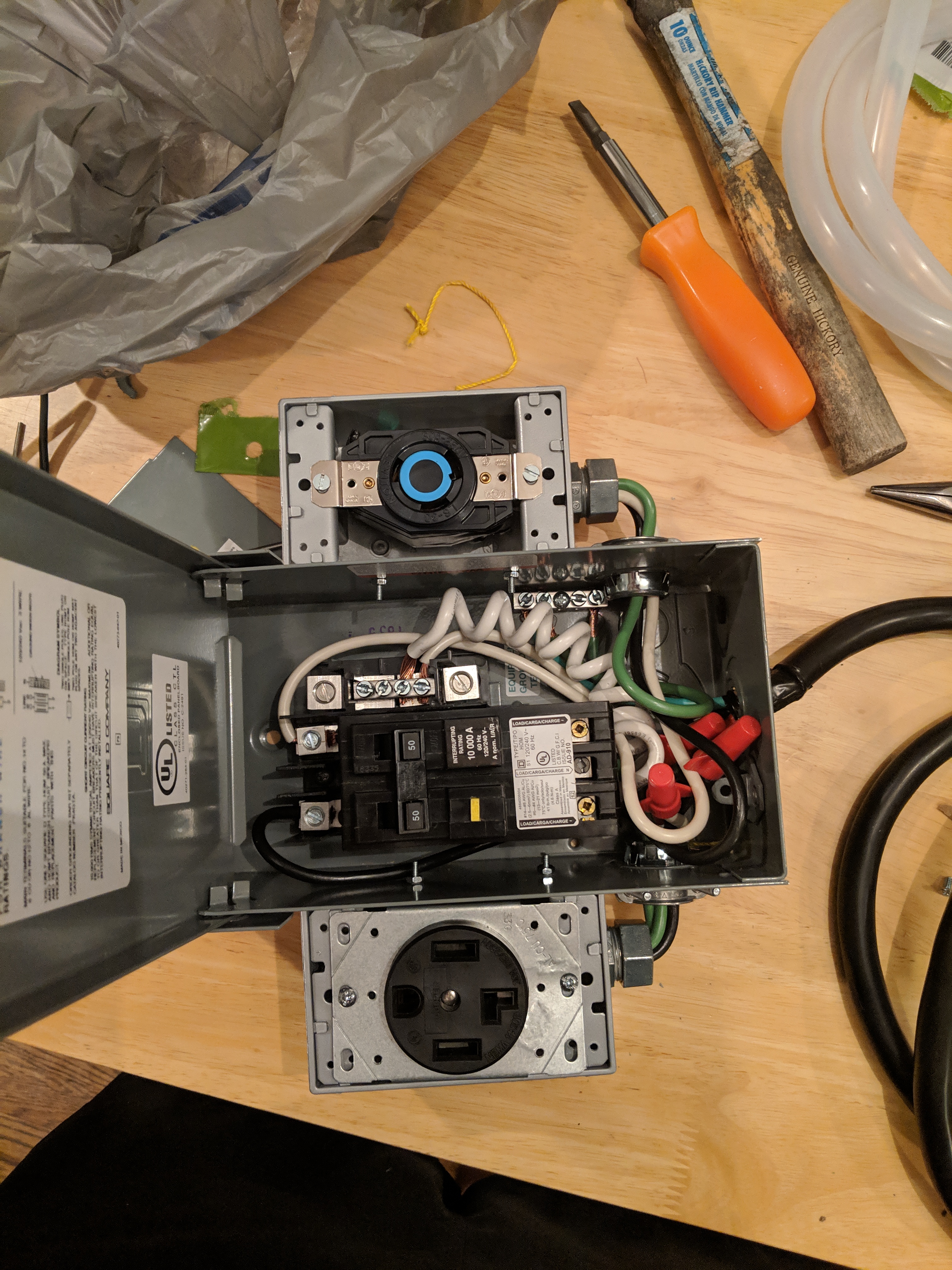

I'm also considering putting 4 ports on the kettle. Three down on the bottom and one on top. One bottom port will be for the valve, one bottom port will be for the 220v heating element, one bottom port will be "extra" and the top port will be "extra" as well. The extra bottom port is for the odd case that I can't get the 220v heating element to work and I can hook up two 110v heating elements, or if I want to set up a pump in the future to do some type of re-circulation (I have no plans at the moment, but I'd rather pay the extra $40 for it now and have the ability to do it than not have the option later), or to just use as a thermometer port. The top port will be for the return of any re-circulation, or whirlpool like function. All ports in TC fittings.

Keeping that in mind, a few questions that I was hoping to get some insight on:

1. Do you think the 15 gallon kettle is overkill?

2. Where would you orient the valve bottom port (both left to right and vertical, such as 1.5" or 2" off the bottom)?

3. Where would you orient the other two bottom ports (both left to right and vertical)? Staggered in height, or not?

4. Where would you orient the top port?

5. Should I be looking at going for 1.5" or 2" TC ports?

6. What type of 220v heating element should I be looking for? I can do wiring myself, but welding is not in my ability.

7. Should I be considering getting a false bottom? I don't have any experience with these.

8. What type of pickup tube should I be considering?

9. Is there anything else I should be considering? I.e. what would you do differently if you were to build your kettle all over again?

Thanks for the thoughts and help.

My design is to use the kettle as both the mash tun and the kettle with an electronic heating element. I have no plans to go fully automated, or use a temp controller, or a HERMS or similar system. I was hoping to do no sparge batches moving forward. So I was considering going with a 15 gal kettle size, in order to allow me to do full volume no sparge, high gravity batches. I assumed a 10 gallon kettle, with 7.5 gallons of water (for the odd 90 min boil) and 15 lbs of grain won't go over too well space wise. So the 15 gallon kettle will give me a little more flexibility (even though I realistically speaking don't ever plan on doing 10 gallon batches).

I'm also considering putting 4 ports on the kettle. Three down on the bottom and one on top. One bottom port will be for the valve, one bottom port will be for the 220v heating element, one bottom port will be "extra" and the top port will be "extra" as well. The extra bottom port is for the odd case that I can't get the 220v heating element to work and I can hook up two 110v heating elements, or if I want to set up a pump in the future to do some type of re-circulation (I have no plans at the moment, but I'd rather pay the extra $40 for it now and have the ability to do it than not have the option later), or to just use as a thermometer port. The top port will be for the return of any re-circulation, or whirlpool like function. All ports in TC fittings.

Keeping that in mind, a few questions that I was hoping to get some insight on:

1. Do you think the 15 gallon kettle is overkill?

2. Where would you orient the valve bottom port (both left to right and vertical, such as 1.5" or 2" off the bottom)?

3. Where would you orient the other two bottom ports (both left to right and vertical)? Staggered in height, or not?

4. Where would you orient the top port?

5. Should I be looking at going for 1.5" or 2" TC ports?

6. What type of 220v heating element should I be looking for? I can do wiring myself, but welding is not in my ability.

7. Should I be considering getting a false bottom? I don't have any experience with these.

8. What type of pickup tube should I be considering?

9. Is there anything else I should be considering? I.e. what would you do differently if you were to build your kettle all over again?

Thanks for the thoughts and help.