bioguy

Well-Known Member

- Joined

- Mar 24, 2005

- Messages

- 170

- Reaction score

- 23

I need your creativity and experience for my parti-gyle brewery build. Because my brewery evolved and was not intelligently designed it is a bit convoluted. Please bear with me. I finally found the money to invest in a pump, and I need a little help with the design of the plumbing. I'm going to tell you how I currently brew. It's a little different from most of the systems I see you guys using.

I use the parti-gyle method to brew three - 5 gallon batches at a time. For example, I recently brewed a Barley Wine, strong IPA, and a weak pale ale. I'll use this as my example

I have 3 brew kettles which are approximately 7 gallons.

I have 2 mash tuns made out of coolers with slotted manifolds -- one is 12 gallons, rectangular, the other is 10 gallons, circular. I need both to mash 44 lbs of grain.

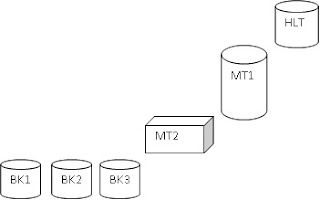

I have an additional 5 gallon cooler (circular) which I use as a hot liquor tank. These are arranged so gravity can help (as shown in the picture below)

1. Fill all 3 kettles with water and bring to mash-in temp.

2. Mash 44 pounds of grain with appx. 15 gallons of water.

3. Mash tun 1 drains into mash tun 2. I recirculate from MT2 into MT1.

4. MT 2 drains into boil kettle (BK) 1. Meanwhile, I add sparge water from BK 2 (heated during mash).

5. Once I have my wort in BK1, I move any remaining sparge water in BK2 to a hot water tank located uphill from MT1. Fill BK2.

6. Move sparge water from BK3 into HLT

7. Fill BK3.

8. By the time BK3 is full, I'm usually done with my boil on kettle 1. This drains down to the basement through PEX tubing into a counterflow chiller and then into a waiting 6.5 gallon carboy.

9. BK2 and BK3 get drained similarly once they are finished.

------------

What I'd like help with is figuring out how to plumb this to use the March Pump I bought.

Each vessel is equipped with a valve at the bottom to drain.

I would like to underlet my mash tuns when I mash in.

Keeping the cost down is a fairly high priority, but brewing good beer without destroying my back is up there too.

Thanks for any help you can give me.

I use the parti-gyle method to brew three - 5 gallon batches at a time. For example, I recently brewed a Barley Wine, strong IPA, and a weak pale ale. I'll use this as my example

I have 3 brew kettles which are approximately 7 gallons.

I have 2 mash tuns made out of coolers with slotted manifolds -- one is 12 gallons, rectangular, the other is 10 gallons, circular. I need both to mash 44 lbs of grain.

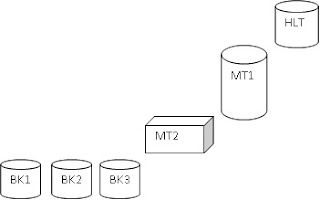

I have an additional 5 gallon cooler (circular) which I use as a hot liquor tank. These are arranged so gravity can help (as shown in the picture below)

1. Fill all 3 kettles with water and bring to mash-in temp.

2. Mash 44 pounds of grain with appx. 15 gallons of water.

3. Mash tun 1 drains into mash tun 2. I recirculate from MT2 into MT1.

4. MT 2 drains into boil kettle (BK) 1. Meanwhile, I add sparge water from BK 2 (heated during mash).

5. Once I have my wort in BK1, I move any remaining sparge water in BK2 to a hot water tank located uphill from MT1. Fill BK2.

6. Move sparge water from BK3 into HLT

7. Fill BK3.

8. By the time BK3 is full, I'm usually done with my boil on kettle 1. This drains down to the basement through PEX tubing into a counterflow chiller and then into a waiting 6.5 gallon carboy.

9. BK2 and BK3 get drained similarly once they are finished.

------------

What I'd like help with is figuring out how to plumb this to use the March Pump I bought.

Each vessel is equipped with a valve at the bottom to drain.

I would like to underlet my mash tuns when I mash in.

Keeping the cost down is a fairly high priority, but brewing good beer without destroying my back is up there too.

Thanks for any help you can give me.