Hey all,

Just thought I would share my build as it is finally under way! Before we go any further, the reasoning behind this build: I live in a downtown apartment where I don't have easy outdoor access for propane brewing or 240v in the apartment. I started off doing 1 to 3 gallon all grain brews on my stove top, which worked pretty well. But when I tried to go 5g, the stove just wouldn't cut it, and while I have got by with partial boils (adding water at chilling and a accounting for higher boil gravities and lower hop utilization), I find the process less consistent than I would like. Additionally I felt like I was adding at least an hour to hit strike and boil temps. I also dislike disassembling threaded components, scrubbing them, and removing and replaces thread sealant (leaks in an apartment kitchen are a pain). So I wanted to design a system that would let me do 3 to 5 gallon full boil BIAB batches, preferably using as few threaded connections as possible.

Previous setup:

I have designed, ordered and received my custom Spike eBIAB kettle with all 1.5" TC connections. 4 in total: 2 at 2" from the bottom for my element, and pick up tube, one at 4" which I will use for my temp sensor (could be used for a second 120v element later if desired), and one 2" from the top lip for both mash recirculation and later to be swapped for whirlpool return.

I decided I like the integrated 1.5" TC 5500w ripple element at brewhardware. When run at 120v this yields a watt density of only 15w/in. Additionally as I'm using a single vessel, being able to remove the cord is nice. Bobby at brewhardware was also kind enough to wire up a cable for me at no additional charge. I just payed for the components and he put it all together for me.

The pickup tube I intend to order from Jaybird over at NorCal. I already spoke with him on the phone after exchanging some emails about custom parts and he is also fantastic to deal with! Great guy. I still need to measure for and the pickup tube and order it, but the whirlpool return I have and looks fantastic. The pickup tube will be a side pickup resting on the lip of the bottom of the kettle to help avoid trub carryover.

For now I have a thermowell that I will use to monitor temps with my Chef Alarm, but I will soon have a custom 120v EZBoil controller from BrauSupply with the additional relay output wired to an additional alarm. Also looking forward to playing with that... I mean dialing it in...

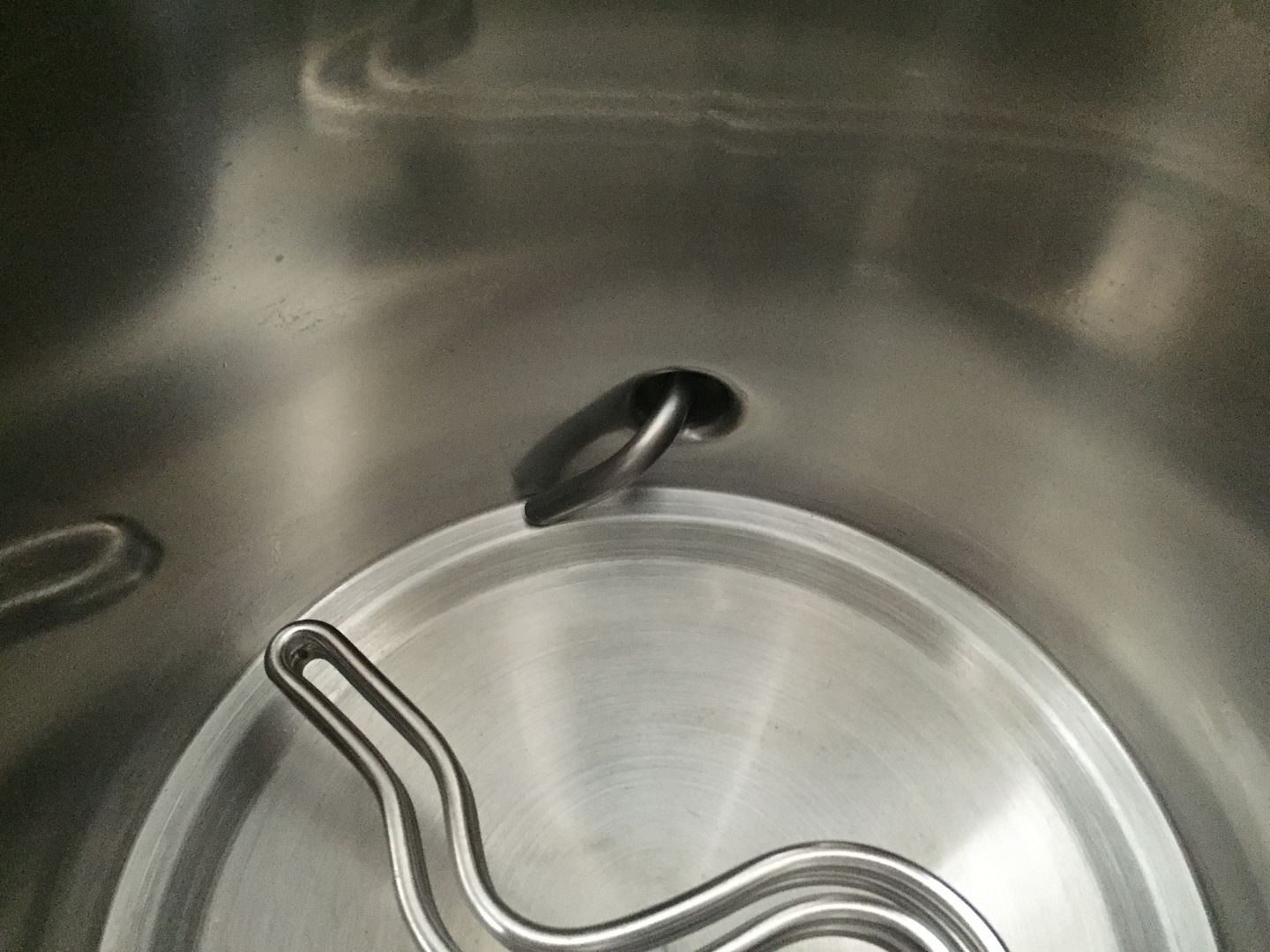

For mash recirculation, I have a loc line set up with the only threaded connection (via a full thread female TC adapter). It wasn't too expensive and i can experiment with it easily enough. Although I may decide to forgo mash recirculation if it becomes more trouble than it's worth.

All ball valves will be easy clean with TC bodies so I have no excuse for not cleaning after each batch. These are quite bulky but the welded TC ports on the Spike kettle are strong and I think this should work well.

So far I have test fit everything. And that went smoothly. I have also time trialed raising 7g of tap water (80F here in Memphis) to strike temp (165F) and boil with the kettle on my large coil stove burner and with the element plugged straight into a independent 120v GFCI plug. I am quite happy with the times considering I couldn't even get 7g to boil really before.

80F --> 165F in 32 minutes (35 with lid off)

165F --> boil in 18 minutes (25 with lid off)

Notes so far:

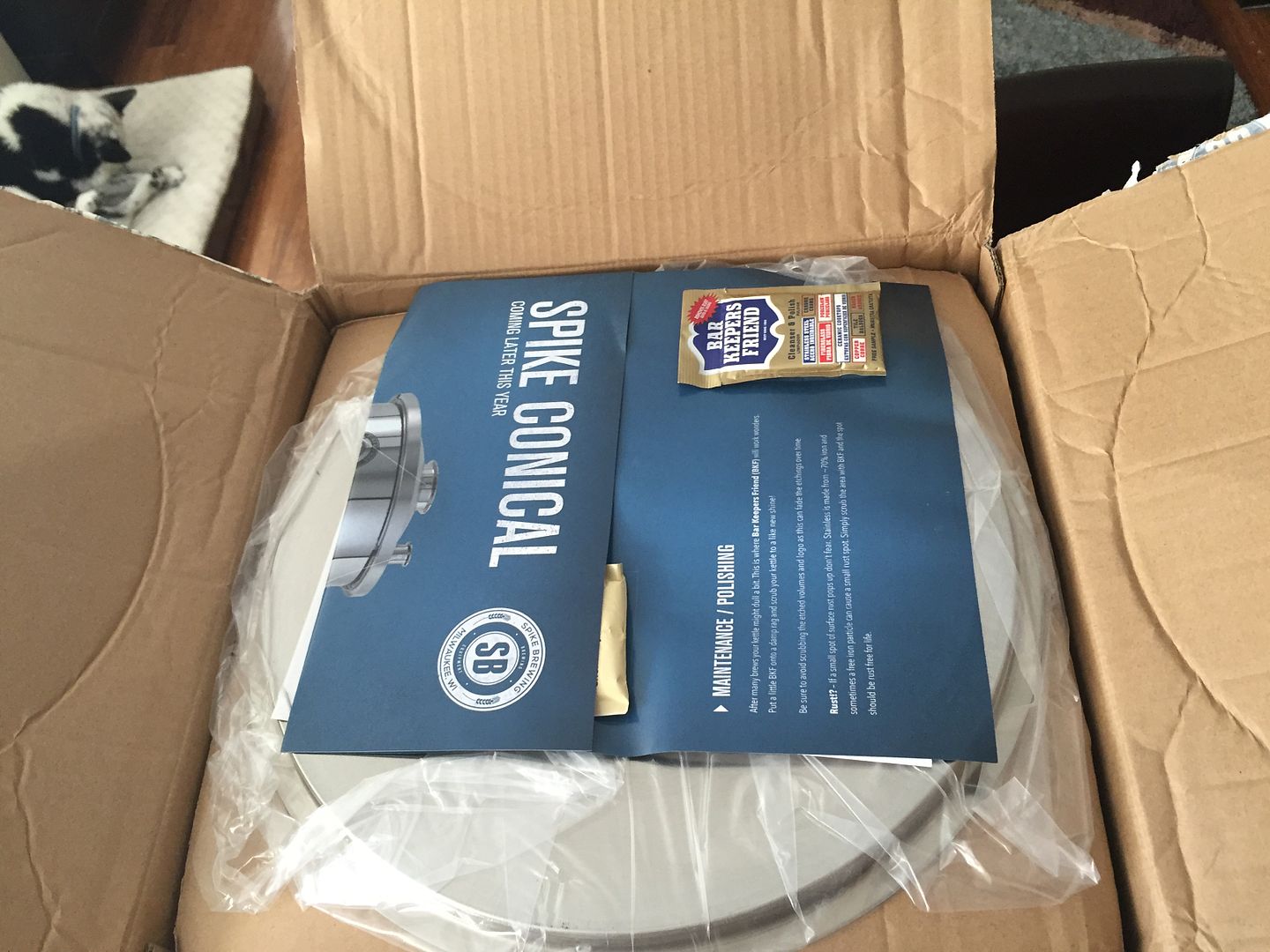

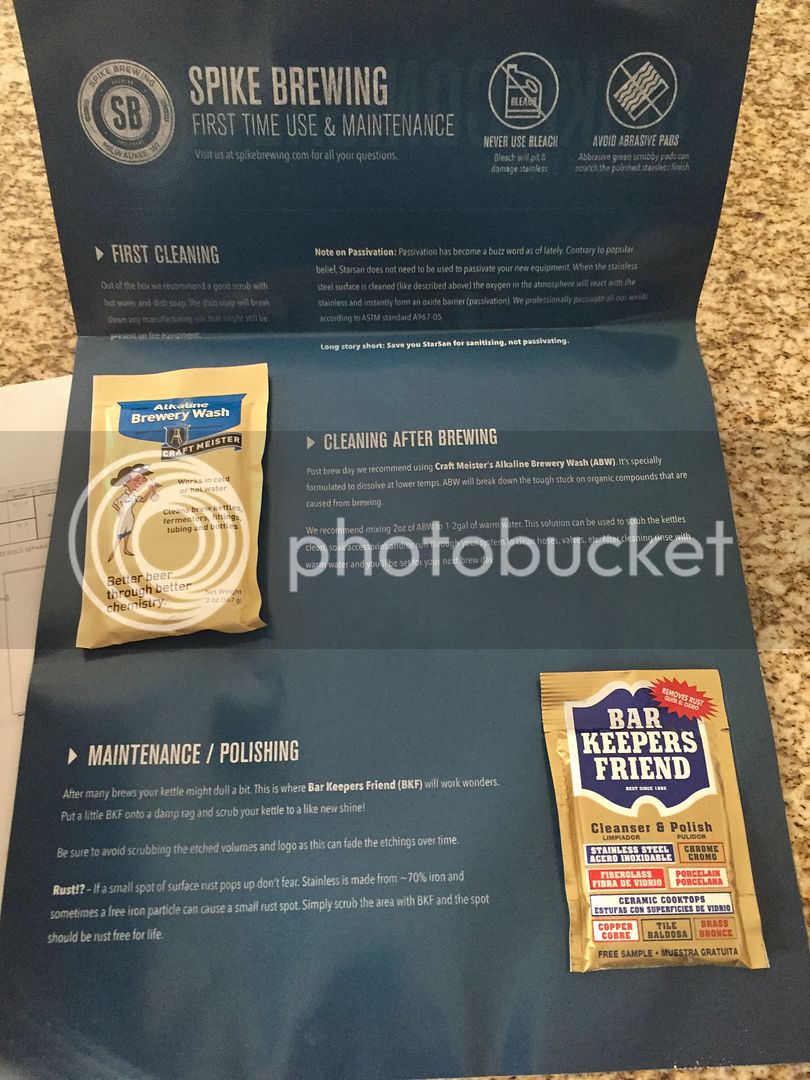

The custom Spike kettle: Spine was really responsive and easy to work with in designing a kettle to suite my personal needs. As I'm am on the stove, all connections are within 180 degrees. The heights I was able to choose with the help of Spikes experience. I got the same $20 discount on my custom order that they are doing on their standand kettles now which was a nice surprise. Overall building and shipping took about 2 weeks from my payment. Shipping could have gone better. The box arrived with the whirlpool TC poking out through the hand hold on one side and suffered a few scrapes and a very minor ding. Again VERY small and I believe to be cosmetic. But could have been avoided in my opinion. Otherwise the kettle looks great. Welds are far far cleaner than my heavy duty kettle from more beer. With no big blobs the try and scrub around. All the ports look great. Only the port I intend to attach my element to is slightly off true (angled up just a few degrees), though you'd be hard pressed to notice. The handles are comfortable, lid is solid and without seems/ rivets to clean. The positioning of the gallon markings works great with my port placement, and it seems Spike has now gone all the way down to 1g which I'm not sure the did before. Overall, very happy with the kettle. Also worth noting Spikecwas dead on with predicting at what volume each port would land which made designing/ planning much easier.

Element: so far so good. Fits the kettle nicely. Is completely submerged by 2g. Seems to function well in initial tests. Prongs seem they may be bent slightly outward from center, and plugging into the cord is slightly tricky. But I'm not experienced with this type of connection do may just be me.

Thermowell: actually the second I bought. First was from pro flow dynamics. That one arrived very poorly packed, was off true, and had a opening too small for all but my stick thermometers. Which may be sufficient for some. But the one I replaced it with from brewers hardware stands out as clearly at better made product. So seams, straight, and with a opening suitable for my inkbird probe or any prove I have for that matter. This is completely submerged at about 3.5g or just under.

Whirlpool: fits nicely and is submerged at 4g. Solid construction from NorCal. Arrived very well packed by the way. Otherwise remains to be tested though.

Well just though I'd share my experiences so far. Let me know what you all think!

Jeff

Just thought I would share my build as it is finally under way! Before we go any further, the reasoning behind this build: I live in a downtown apartment where I don't have easy outdoor access for propane brewing or 240v in the apartment. I started off doing 1 to 3 gallon all grain brews on my stove top, which worked pretty well. But when I tried to go 5g, the stove just wouldn't cut it, and while I have got by with partial boils (adding water at chilling and a accounting for higher boil gravities and lower hop utilization), I find the process less consistent than I would like. Additionally I felt like I was adding at least an hour to hit strike and boil temps. I also dislike disassembling threaded components, scrubbing them, and removing and replaces thread sealant (leaks in an apartment kitchen are a pain). So I wanted to design a system that would let me do 3 to 5 gallon full boil BIAB batches, preferably using as few threaded connections as possible.

Previous setup:

I have designed, ordered and received my custom Spike eBIAB kettle with all 1.5" TC connections. 4 in total: 2 at 2" from the bottom for my element, and pick up tube, one at 4" which I will use for my temp sensor (could be used for a second 120v element later if desired), and one 2" from the top lip for both mash recirculation and later to be swapped for whirlpool return.

I decided I like the integrated 1.5" TC 5500w ripple element at brewhardware. When run at 120v this yields a watt density of only 15w/in. Additionally as I'm using a single vessel, being able to remove the cord is nice. Bobby at brewhardware was also kind enough to wire up a cable for me at no additional charge. I just payed for the components and he put it all together for me.

The pickup tube I intend to order from Jaybird over at NorCal. I already spoke with him on the phone after exchanging some emails about custom parts and he is also fantastic to deal with! Great guy. I still need to measure for and the pickup tube and order it, but the whirlpool return I have and looks fantastic. The pickup tube will be a side pickup resting on the lip of the bottom of the kettle to help avoid trub carryover.

For now I have a thermowell that I will use to monitor temps with my Chef Alarm, but I will soon have a custom 120v EZBoil controller from BrauSupply with the additional relay output wired to an additional alarm. Also looking forward to playing with that... I mean dialing it in...

For mash recirculation, I have a loc line set up with the only threaded connection (via a full thread female TC adapter). It wasn't too expensive and i can experiment with it easily enough. Although I may decide to forgo mash recirculation if it becomes more trouble than it's worth.

All ball valves will be easy clean with TC bodies so I have no excuse for not cleaning after each batch. These are quite bulky but the welded TC ports on the Spike kettle are strong and I think this should work well.

So far I have test fit everything. And that went smoothly. I have also time trialed raising 7g of tap water (80F here in Memphis) to strike temp (165F) and boil with the kettle on my large coil stove burner and with the element plugged straight into a independent 120v GFCI plug. I am quite happy with the times considering I couldn't even get 7g to boil really before.

80F --> 165F in 32 minutes (35 with lid off)

165F --> boil in 18 minutes (25 with lid off)

Notes so far:

The custom Spike kettle: Spine was really responsive and easy to work with in designing a kettle to suite my personal needs. As I'm am on the stove, all connections are within 180 degrees. The heights I was able to choose with the help of Spikes experience. I got the same $20 discount on my custom order that they are doing on their standand kettles now which was a nice surprise. Overall building and shipping took about 2 weeks from my payment. Shipping could have gone better. The box arrived with the whirlpool TC poking out through the hand hold on one side and suffered a few scrapes and a very minor ding. Again VERY small and I believe to be cosmetic. But could have been avoided in my opinion. Otherwise the kettle looks great. Welds are far far cleaner than my heavy duty kettle from more beer. With no big blobs the try and scrub around. All the ports look great. Only the port I intend to attach my element to is slightly off true (angled up just a few degrees), though you'd be hard pressed to notice. The handles are comfortable, lid is solid and without seems/ rivets to clean. The positioning of the gallon markings works great with my port placement, and it seems Spike has now gone all the way down to 1g which I'm not sure the did before. Overall, very happy with the kettle. Also worth noting Spikecwas dead on with predicting at what volume each port would land which made designing/ planning much easier.

Element: so far so good. Fits the kettle nicely. Is completely submerged by 2g. Seems to function well in initial tests. Prongs seem they may be bent slightly outward from center, and plugging into the cord is slightly tricky. But I'm not experienced with this type of connection do may just be me.

Thermowell: actually the second I bought. First was from pro flow dynamics. That one arrived very poorly packed, was off true, and had a opening too small for all but my stick thermometers. Which may be sufficient for some. But the one I replaced it with from brewers hardware stands out as clearly at better made product. So seams, straight, and with a opening suitable for my inkbird probe or any prove I have for that matter. This is completely submerged at about 3.5g or just under.

Whirlpool: fits nicely and is submerged at 4g. Solid construction from NorCal. Arrived very well packed by the way. Otherwise remains to be tested though.

Well just though I'd share my experiences so far. Let me know what you all think!

Jeff