Hi All,

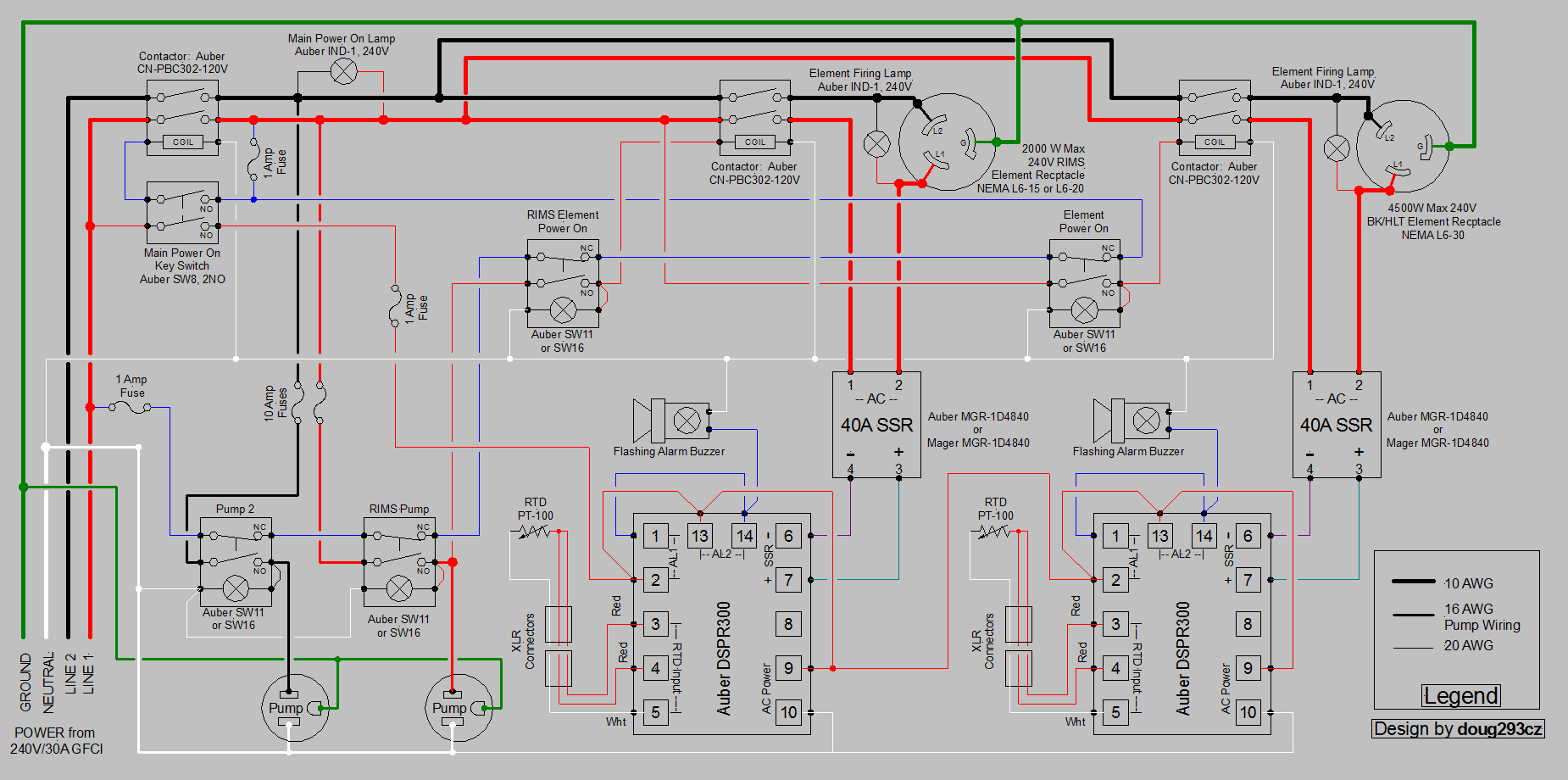

I have finally decided to make the jump from propane fired 3 vessel AG brewing, to fully electric/HERMS/PID controlled brew setup in my basement. As an engineer, and a guy who likes to build stuff, I've decided to build up my own panel. Here are the projected specs:

3 vessel eHERMS with 2x 5500W elements (likely to be stout kettles, but not 100% sure on that, definitely up for some other reccomendations)

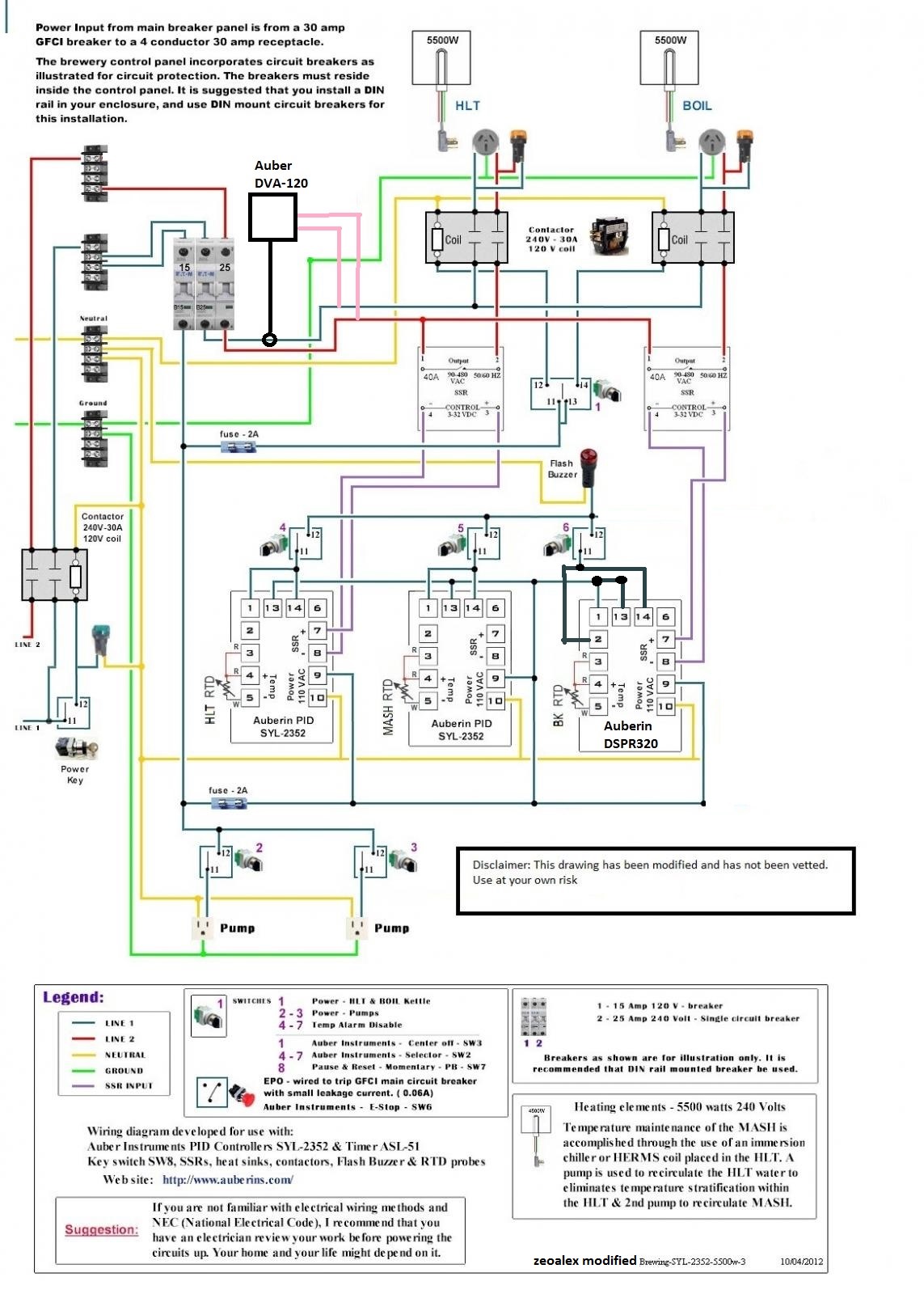

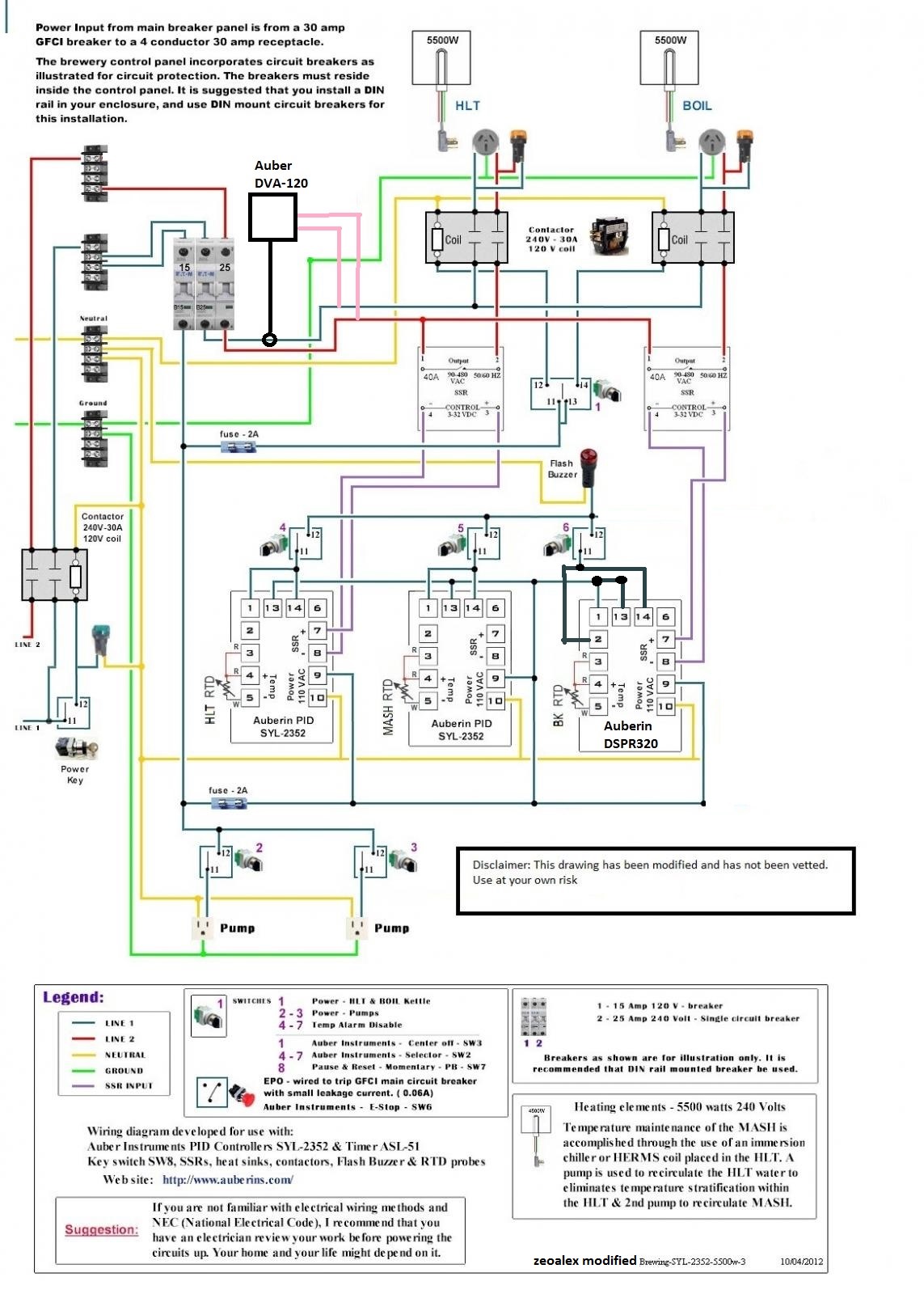

For some reason I seriously struggled to find a diagram with exactly what I was looking for. I did end up finding a pre-modified P-J drawing that has basically everything i wanted, but I still decided to modify it with the following:

Removed E-stop - This drawing has a short-to-ground E stop setup which I've read is sort of frowned upon, and I don't know if an E-stop is really going to be necessary. Worst case I'll add one in, via a contactor

Added DVA-120, I believe to be wired in correctly to see the voltage/amperage across the heating elements

Swapped the BK PID for an Auber EZBoil DSPR320 and wired the second alarm.

A few questions just to make sure my understanding of everything is correct:

Everything north of the SSR's (ie: Any wiring coming out of 25A fuses) should be 10AWG correct? since that sees 240V?

Everything south of the SSR's (anything coming out of the 15A fuse) can be 14AWG?

the SSR Input wiring can be 14AWG or smaller?

Thanks for the once-over! I'm excited to get this project moving!

I have finally decided to make the jump from propane fired 3 vessel AG brewing, to fully electric/HERMS/PID controlled brew setup in my basement. As an engineer, and a guy who likes to build stuff, I've decided to build up my own panel. Here are the projected specs:

3 vessel eHERMS with 2x 5500W elements (likely to be stout kettles, but not 100% sure on that, definitely up for some other reccomendations)

- 240A 14-30R Dryer outlet

- 30A GFCI Breaker

- 2x 120V pumps (showing as wired to rotary switches - may change to NO buttons)

- 1x 3 position switch to choose which element is firing

- 2x Auber PID controls for HLT and MLT (May swap out for a MYPIN TA4, haven't fully decided)

- 1x Auber EZboil DPSR320

- 3x Auber RTDs (planning on using 6" RTDs)

- 3x rotary switches for PID alarm on/off

- 1x flash buzzer

- 2x indicator lights between Contactor and heating element (shouldn't energize from leakage, the elements should never be unplugged)

- 1x main power indicator light

- 1x keyed main power switch

- 1x auber DVA-120 LED vold/ammeter

For some reason I seriously struggled to find a diagram with exactly what I was looking for. I did end up finding a pre-modified P-J drawing that has basically everything i wanted, but I still decided to modify it with the following:

Removed E-stop - This drawing has a short-to-ground E stop setup which I've read is sort of frowned upon, and I don't know if an E-stop is really going to be necessary. Worst case I'll add one in, via a contactor

Added DVA-120, I believe to be wired in correctly to see the voltage/amperage across the heating elements

Swapped the BK PID for an Auber EZBoil DSPR320 and wired the second alarm.

A few questions just to make sure my understanding of everything is correct:

Everything north of the SSR's (ie: Any wiring coming out of 25A fuses) should be 10AWG correct? since that sees 240V?

Everything south of the SSR's (anything coming out of the 15A fuse) can be 14AWG?

the SSR Input wiring can be 14AWG or smaller?

Thanks for the once-over! I'm excited to get this project moving!

Last edited: