Just listened to one of the 2016 conference seminars on oxidation...... if you think it is depressing trying to figure out how to eliminate oxygen pick up transferring from fermenter to keg.... Give this a listen (if you can access it without being an AHA member???). You will be ready to give up entirely.

He talks about the impact of oxidation at every phase. The most depressing part is when he talks about the introduction of oxygen during the mash and the fact that enough oxygen is introduced in standard mashing processes to be well over the threshold. Big production breweries are actually going to nitrogen flushed mash tuns.

At that point I just thought.... well, that is never going to happen on the homebrew level.

https://www.homebrewersassociation....on16 - Identifying and Avoiding Oxidation.mp3

To be honest, while I acknowledge that the "industry standard" for oxygen in beer is very, very low. I don't think there are any home brewers achieving that over the course of their entire process. And, if some are, it is a tiny, tiny piece of a single percentage.

I would be curious if at some point there is simply a threshold that is above industry standard, but below what 90%+ beer drinkers can ever really notice as a detrimental effect in their beer. Basically, if no one can taste a certain level of a "problem", is it actually a problem?

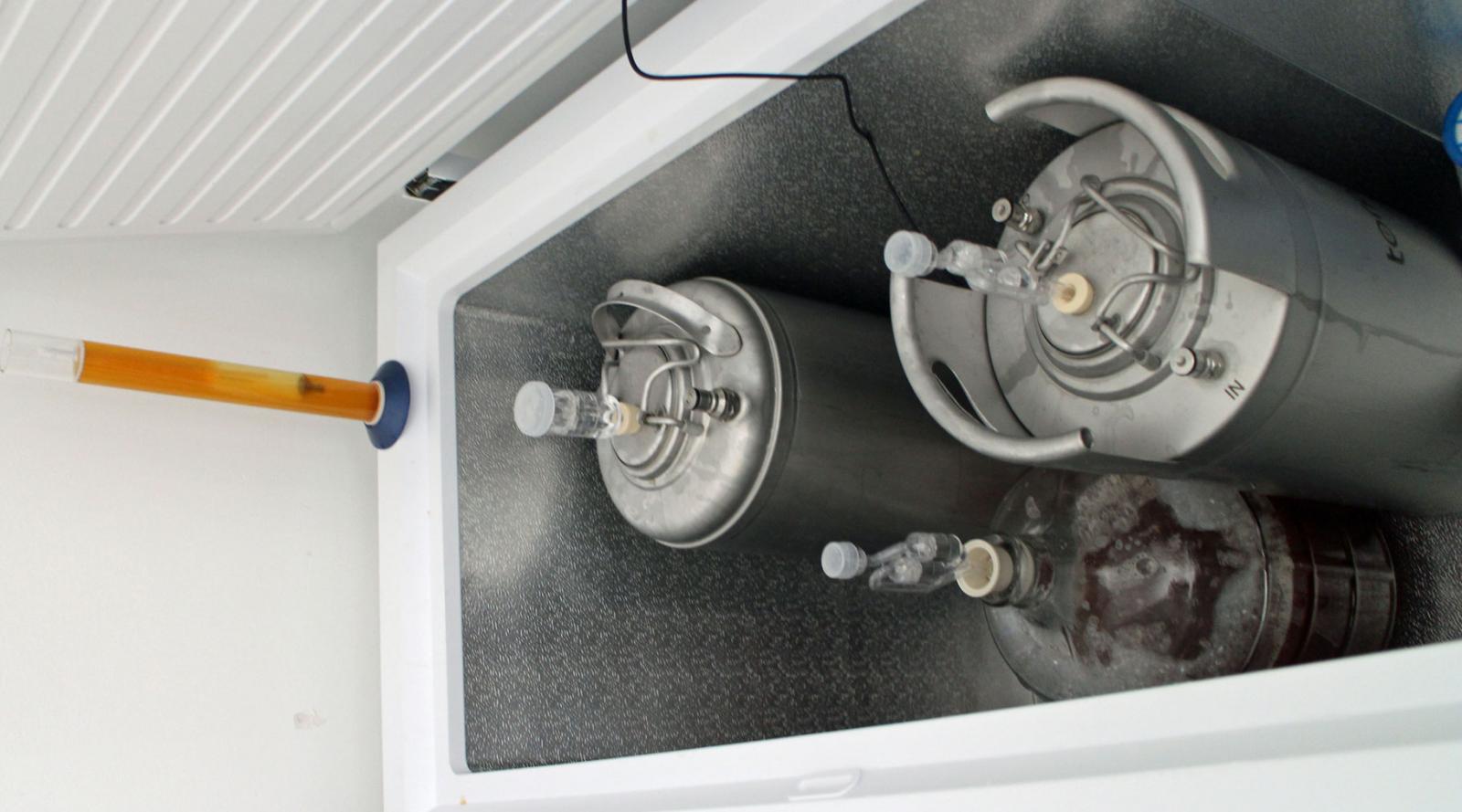

With that said, everyone should take as much care as they can not to introduce oxygen - especially at the points they can control. I like the tip someone mentioned about turning the keg upside down and venting out the CO2 post to get the last bit of star san out in a keg with a short tube (I use one for dry hopping sometimes). Filling the keg with star san and pushing out with CO2 is absolutely the way to go - simple, efficient, effective.

) down to the bottom of the gas in pickup. Oversizing batches by a gallon or two helps still end up with full kegs.

) down to the bottom of the gas in pickup. Oversizing batches by a gallon or two helps still end up with full kegs.