Ckalnasy

Member

- Joined

- Feb 13, 2018

- Messages

- 9

- Reaction score

- 7

Hey guys, new to the forum and I figure I would share my bar build for the new house my wife and I bought end of last year. The basement had a pretty large rec room (close to 30x30) with a bar already in it. Plan was to update the bar, flooring, and new paint. We still have yet to paint the room and decorate everything and then move everything into the rest of the room. When finished the room will have the bar, a pool table area (previous owners left the pool table per my request), a couch/tv area, and a music area (I have a large drumset and lots of buddies who play guitar and we jam often).

Now to the bar…...

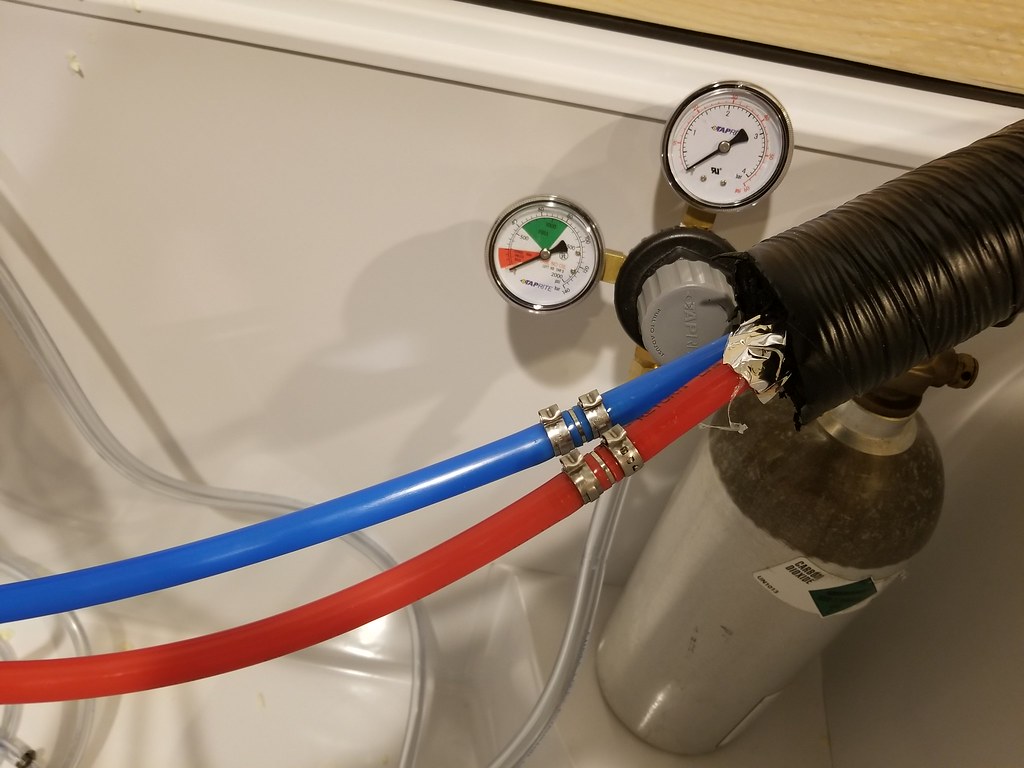

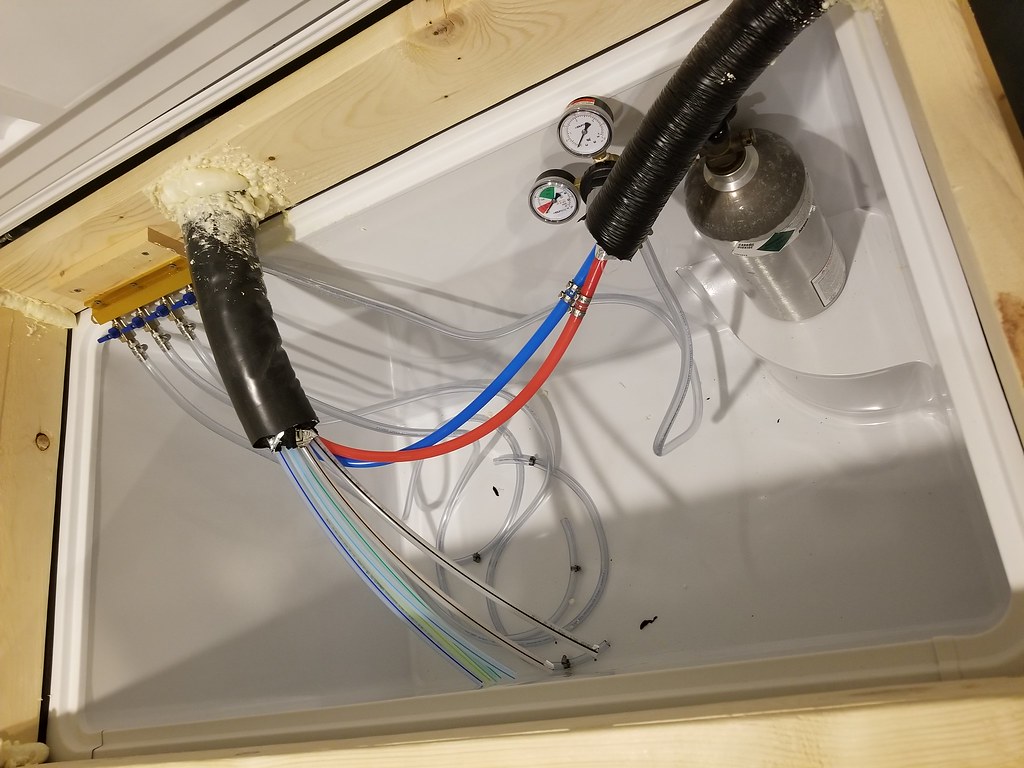

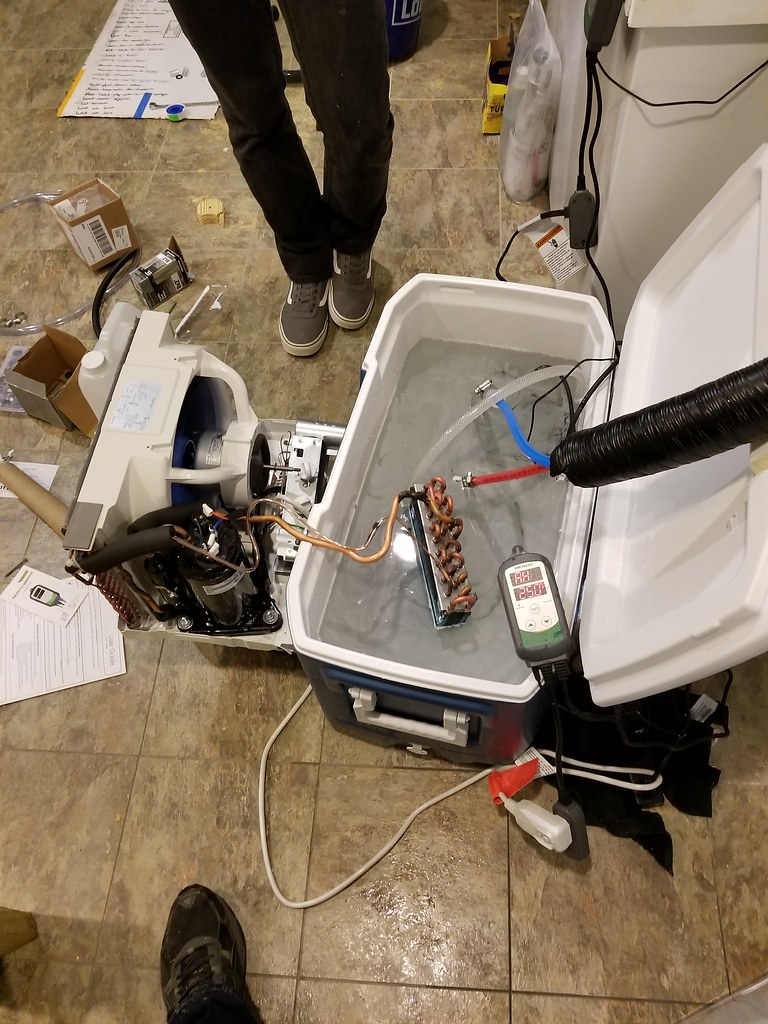

Originally we just wanted to replace the counter tops and that was going to be it, but the mini fridge area under the bar was small, so either cut up cabinets or stick a large fridge in the room off of this rec room. Quickly after having a pow wow with my brother, he dropped the idea of a kegerator system. Now, I already have a garage fridge that was converter into a double kegerator, so I knew the basics of what I was getting into. But, it quickly grew into a remote keezer system with a large trunk line and glycol, etc etc. Lets get to some pics!

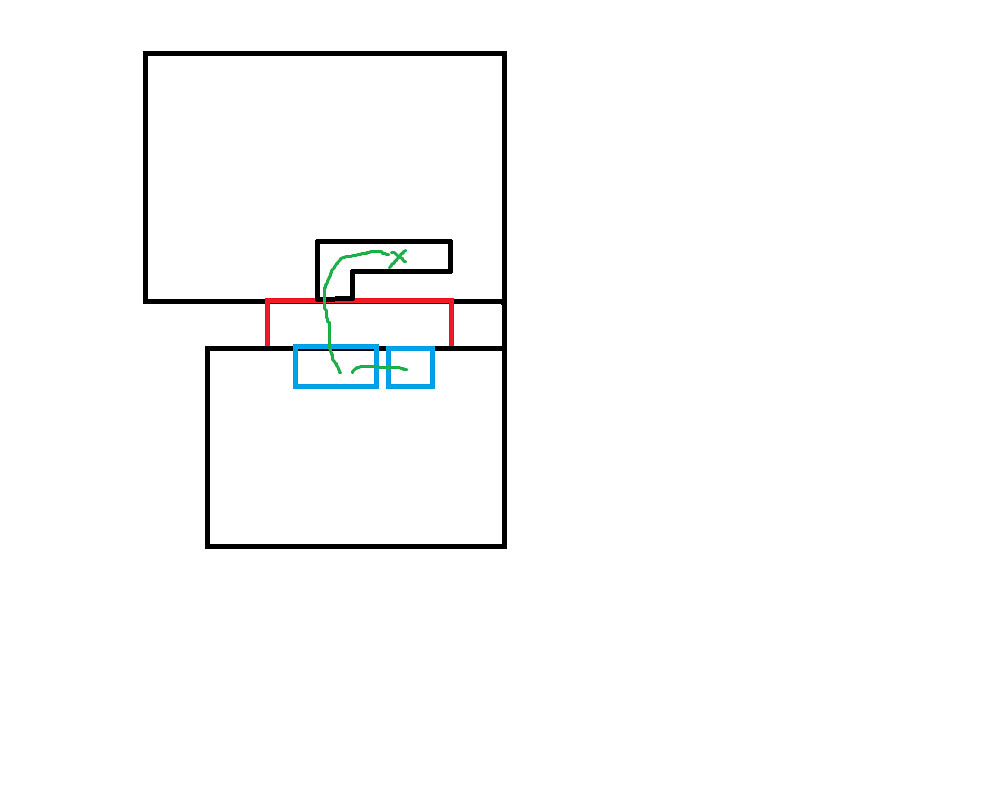

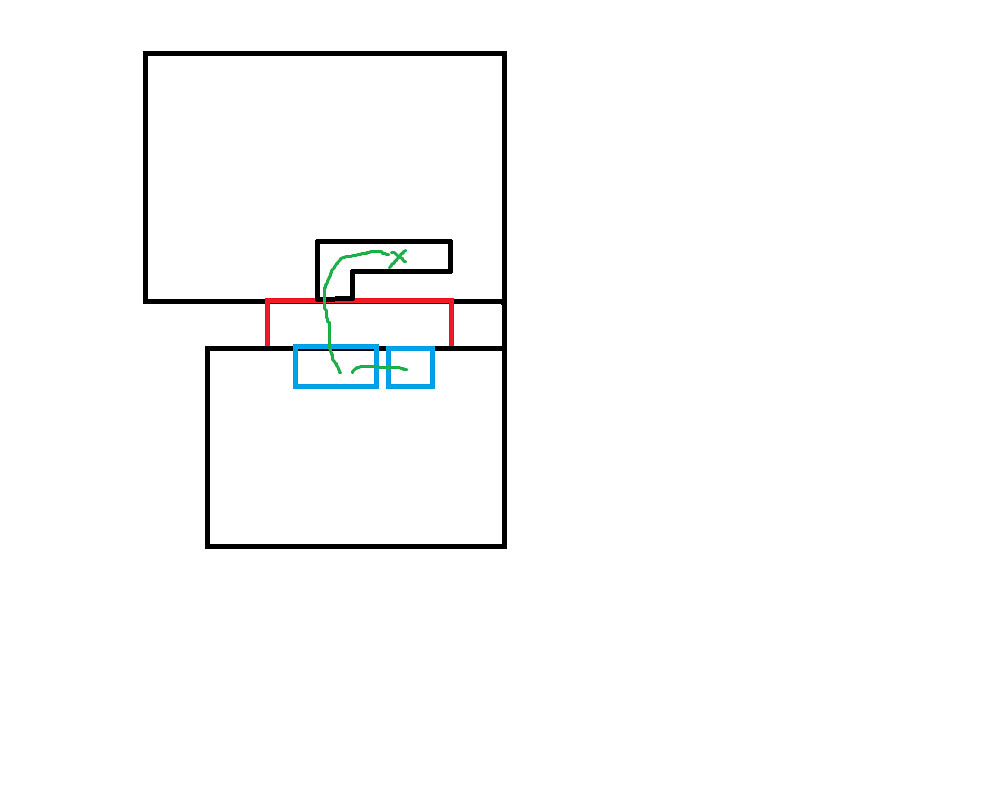

Here is a quick paint sketch I made of the area. The upper room is the rec room. The lower room is the extra storage room off of that. The black ‘L’ shape is the bar itself. In red is the staircase coming down into the basement and is also an unfinished room between the two that has the a/c system and is where the trunk line runs through. In blue is the keezer with the kegs and also the glycol freezer. And finally in green are the trunk lines. This should give you guys an idea of the layout.

Pictures of the bar area before demo….

So we started with getting the carpet up in the room as well as all of stick down tile. The stick down tile was an absolute pita to get up, so I used my torpedo heater to heat the tiles up, my buddy used a floor scraper to start getting it to come up and I will pull it the rest of the way.

Then we started to lay down the tile. 12x24 tiles in a herringbone-esque laying pattern.

And then time for some light gray grout…..

And then we removed the old countertops. This was the time we ran the trunk line for the keg system as it made the most sense with the counters off. We used a hole saw from the unfinished staircase room and drilled through the cabinet under the sink and then ran it around. Also took the cabinet drawer and shortened it by about 12” to leave plenty of room for the trunk line coming up and meeting with the tap tower.

Now to the bar…...

Originally we just wanted to replace the counter tops and that was going to be it, but the mini fridge area under the bar was small, so either cut up cabinets or stick a large fridge in the room off of this rec room. Quickly after having a pow wow with my brother, he dropped the idea of a kegerator system. Now, I already have a garage fridge that was converter into a double kegerator, so I knew the basics of what I was getting into. But, it quickly grew into a remote keezer system with a large trunk line and glycol, etc etc. Lets get to some pics!

Here is a quick paint sketch I made of the area. The upper room is the rec room. The lower room is the extra storage room off of that. The black ‘L’ shape is the bar itself. In red is the staircase coming down into the basement and is also an unfinished room between the two that has the a/c system and is where the trunk line runs through. In blue is the keezer with the kegs and also the glycol freezer. And finally in green are the trunk lines. This should give you guys an idea of the layout.

Pictures of the bar area before demo….

So we started with getting the carpet up in the room as well as all of stick down tile. The stick down tile was an absolute pita to get up, so I used my torpedo heater to heat the tiles up, my buddy used a floor scraper to start getting it to come up and I will pull it the rest of the way.

Then we started to lay down the tile. 12x24 tiles in a herringbone-esque laying pattern.

And then time for some light gray grout…..

And then we removed the old countertops. This was the time we ran the trunk line for the keg system as it made the most sense with the counters off. We used a hole saw from the unfinished staircase room and drilled through the cabinet under the sink and then ran it around. Also took the cabinet drawer and shortened it by about 12” to leave plenty of room for the trunk line coming up and meeting with the tap tower.