Bottlebomber, I know of a few people who have had their houses blow up over butane extractions. The bottom line.. doing the BULK of a butane extraction INDOORS is completely UNSAFE. And for legal purposes, it should not be promoted on this forum.

If anyone wants to do a SAFE butane extraction, make sure to carry out the BULK extraction OUTDOORS.

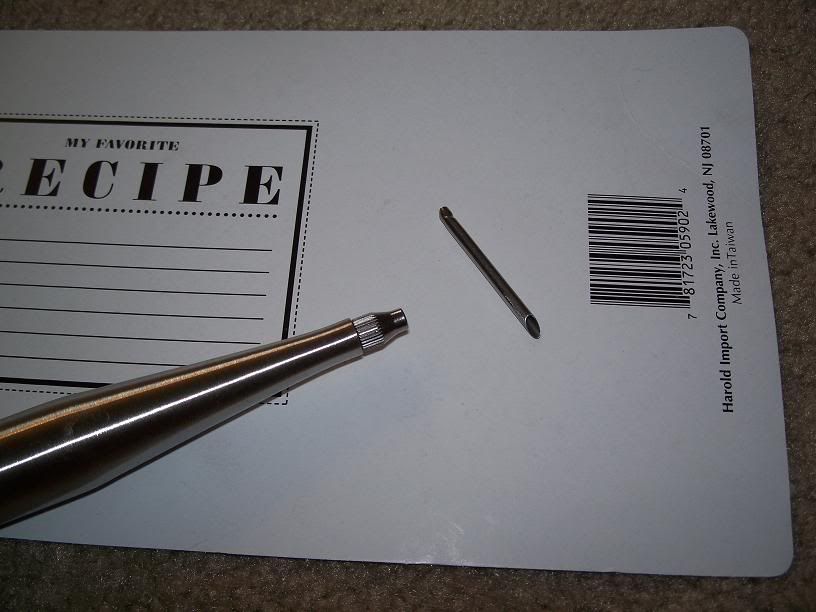

A suitable-cheap extraction tube is a SS turkey baster that can be bought from bed, bath, and beyond for around $5. All you need to do is break of the needle (which just so happens to fit most butane can tips perfectly), remove the rubber bulb, pack it tightly full of hops, and zip-tie a coffee filter onto the wider end of the apparatus.

A pyrex plate can then be placed in a preheated bath of water and carried OUTSIDE (140-160F is about what I shoot for with my water baths). Spraying about 1/2 of a 300ml can is enough for a full extraction (suitable brands include Colibre, Vector, and Lucienne). Make sure to hold the extraction tube with a cloth or oven mits because it will get extremely cold during the spray. Once the bulk amount of liquid has evaporated to a resiny film, then it is safe to bring inside and put your water bath on the stove for the final purge.

The bubbles are full of butane and are in fact still flammable, but it wont be in such a great concentration to cause an explosion. Keep the temperatures to about 150F throughout the purge.. which can last about 10-20 minutes depending on the yield. The bubbles can be manually raised throughout the process with a metal poker or a knife. By doing this final purge, you are removing the remaining amount of butane still contained within your tincture. If you see a yellow foam, it is just butane being removed.. stirring it multiple times with poker can release these bubbles during the final purge.

As a final note, overcooking your extract can rid your product of terpenes which imparts a lot of aroma into your tincture. The goal is to get a product full of aroma, yet doesn't have any residual impurities left behind from the butane. This will take practice to know when your product is done.

Don't be stupid.. butane is extremely flammable with explosive results in an enclosed space. Something as simple as a heater kicking on can set off an irreversible chain reaction.