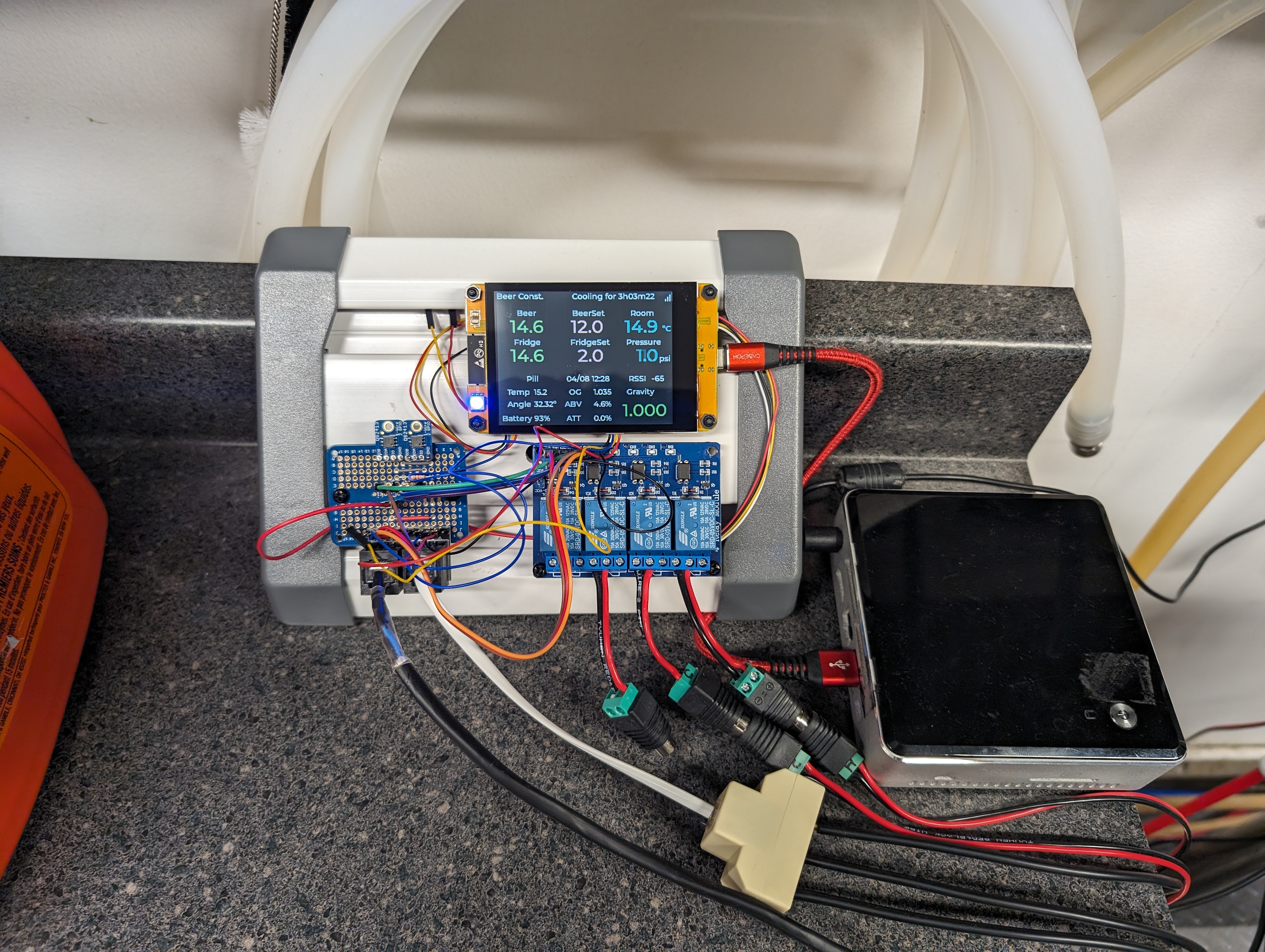

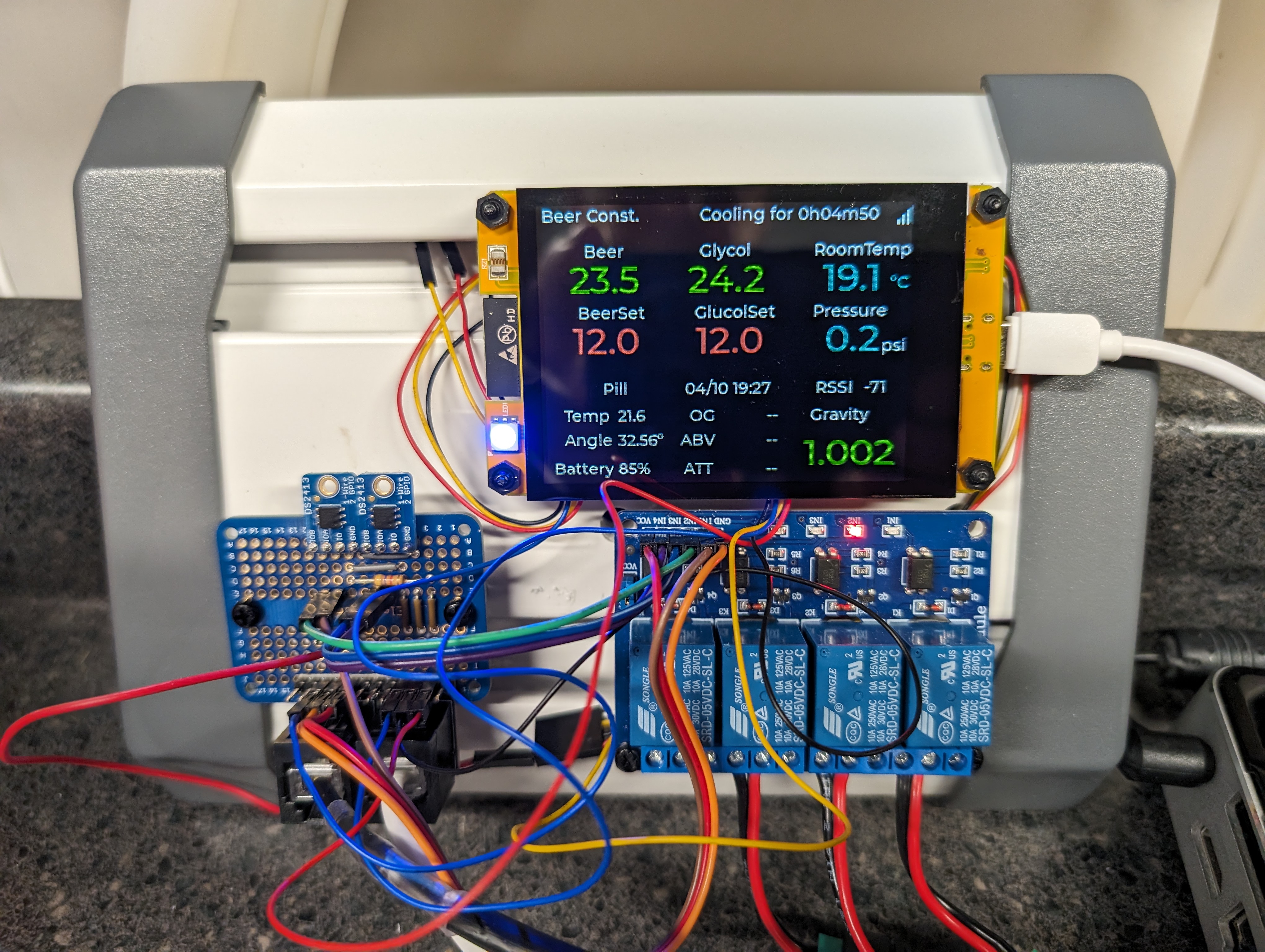

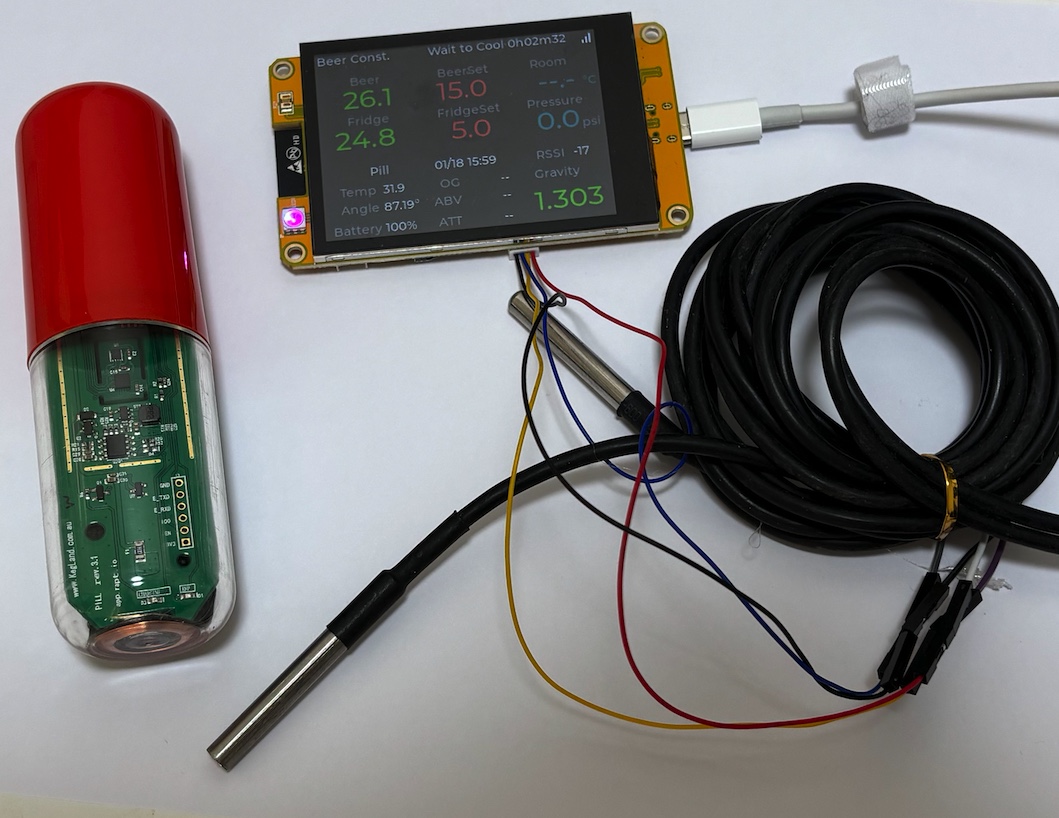

I know, I know. The old 20x4 LCD looks like coming from last century. We now have cheap TFT display with touch control. So, here it is.

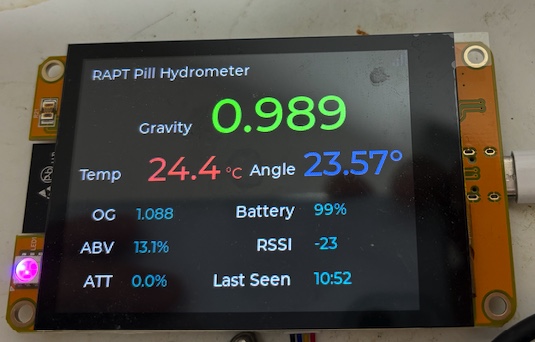

Forgive my bad naming skill/taste. BrewPiLessGx is a BrewPiLess with Graphics interface. So the display enables us to

- Set control mode and temperature with touched screen

- Select network and enter pass phrase

- Display the infomration in the way as desired. I created a JSON format for describing what and how the information is shown. It is so flexible that I am thinking about creating an editor for it.

(I am bad at hard ware building. It would take too long to verify. Therefore, I will make a beta release soon, so that people interested can try it.)

To Be continue...