Brew day today and I have some time to document the process, so what the heck.

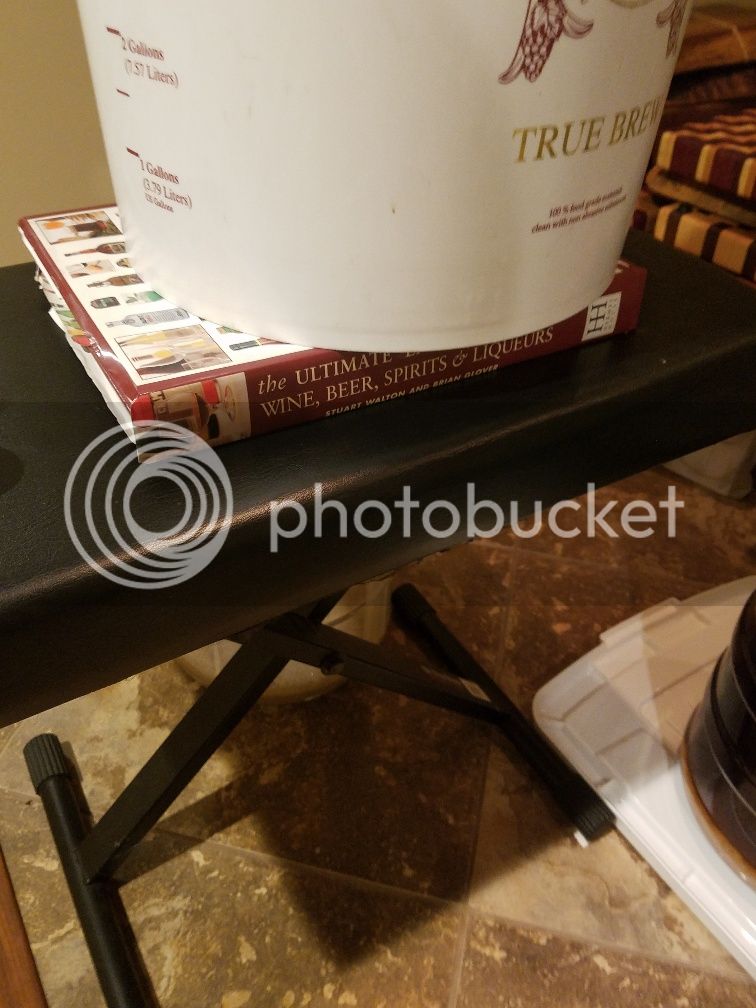

The setup:

Simple 32 qt turketfryer with basket, propane burner, homemade immersion chiller, cleanser, Starsan, bucket and thermometer / timer.

The recipe:

I have 10# of West Branch Ohio grown and malted 2 row, so we are going to make a local single malt and single hop pale ale. 4 oz of 9.5 % AA centennials will be used in this, 1/2 in the boil, half at flameout.

Water is important. The German's use theirs, the English use theirs, I like to use mine. Unfortunately it is extremely hard, so I have an RO system for drinking water with a 20 gal tank for storage. If I didn't have RO water, I would use distilled water. Need about 7 gallons for this recipe. I marked the inside of my bottling bucket with a sharpie so I can see the graduated marking on the outside and use this to measure.

I designed this recipe with 10# of barley being the gating factor. Based on the SG / IBU balance I want, Beersmith tells me a 4 gallon batch is optimal. If you are a beginner, an all grain kit from the LHBS is the way to go. I have two 2 oz packs of centennials I want to use, and once they are open I want to use them all, so I adjust the quantities and timing of the additions to get to the IBU's I want, with the smallest additions going first and building upon that.

A word of warning, now is a good time to open your hops and smell them. If they smell like grapefruit and citrus, heaven. If they smell cheesy, take them back and get new ones.

Yeast will be some WLP001 American Ale yeast I resurrected from 2 years of storage in my fridge. You can easily use WLP from the tube, a smack pack or dry yeast and pitch this directly in the fermentor.

Finally, we'll throw a whirlflok tablet in with 15 minutes left in the boil to help this beer clear.

10# - 2 row Pale Ale malt

.5 oz - Centennial at 60 minutes

.5 oz - Centennial at 30 minutes

1 oz - Centennial at 15 minutes

2 oz Centennials at flame out

1 - whirlflok tablet at 15 minutes

4 gallon yield with targets of 1.058 SG and 47.1 IBU , 5.8% ABV.

The Mash:

I want a medium bodied pale ale mashed in at 152F. I want as much strike water as possible, so I have Beersmith setup with my pot size and reserving .2 gallons as a post mash addition, gets me to 24 quarts of strike water at 162F. My last three batches have all overshot their mash in temps by 3 degrees, and I'd rather be under on this one that over, so we will shoot for a 159F mash in temp to get to 152F and let it mash for 75 minutes.

And after about 5 minutes of stirring we hit 152 and cover it up.

I stir from the middle to the edge of the pot and lift my paddle up the edges to the brim\and make my way 360 degrees around the pot. Doughballs come up the side pretty easily and a few times around the cycle you'll see them completely disappear. I put the thermometer probe through a binder clip attached to the basket handle. A big plus for using the basket is clipping to the handle to get a good angle to the wort.

A word about the grain. I have a barley mill and it's been set to the same setting for years. It's pretty middle of the road and cracks all of the husks. I could go finer, but it works, and my 18V drill needs a newly charged battery to power through it now, so I haven't messed with adjusting it. Plus I still have a 10 gallon cooler setup and don't want to have to adjust it back.

I've also had grain crushed at the my LHBS and they do a nice job as well. I love having the barley crusher, but it is not a mandatory piece.

And it's now after noon, so that means:

After 45 minutes our mash temp has dropped to 143, so I fire up the pot for 5 minutes and stirring pretty constantly get it up to 148.

TBC.......

The setup:

Simple 32 qt turketfryer with basket, propane burner, homemade immersion chiller, cleanser, Starsan, bucket and thermometer / timer.

The recipe:

I have 10# of West Branch Ohio grown and malted 2 row, so we are going to make a local single malt and single hop pale ale. 4 oz of 9.5 % AA centennials will be used in this, 1/2 in the boil, half at flameout.

Water is important. The German's use theirs, the English use theirs, I like to use mine. Unfortunately it is extremely hard, so I have an RO system for drinking water with a 20 gal tank for storage. If I didn't have RO water, I would use distilled water. Need about 7 gallons for this recipe. I marked the inside of my bottling bucket with a sharpie so I can see the graduated marking on the outside and use this to measure.

I designed this recipe with 10# of barley being the gating factor. Based on the SG / IBU balance I want, Beersmith tells me a 4 gallon batch is optimal. If you are a beginner, an all grain kit from the LHBS is the way to go. I have two 2 oz packs of centennials I want to use, and once they are open I want to use them all, so I adjust the quantities and timing of the additions to get to the IBU's I want, with the smallest additions going first and building upon that.

A word of warning, now is a good time to open your hops and smell them. If they smell like grapefruit and citrus, heaven. If they smell cheesy, take them back and get new ones.

Yeast will be some WLP001 American Ale yeast I resurrected from 2 years of storage in my fridge. You can easily use WLP from the tube, a smack pack or dry yeast and pitch this directly in the fermentor.

Finally, we'll throw a whirlflok tablet in with 15 minutes left in the boil to help this beer clear.

10# - 2 row Pale Ale malt

.5 oz - Centennial at 60 minutes

.5 oz - Centennial at 30 minutes

1 oz - Centennial at 15 minutes

2 oz Centennials at flame out

1 - whirlflok tablet at 15 minutes

4 gallon yield with targets of 1.058 SG and 47.1 IBU , 5.8% ABV.

The Mash:

I want a medium bodied pale ale mashed in at 152F. I want as much strike water as possible, so I have Beersmith setup with my pot size and reserving .2 gallons as a post mash addition, gets me to 24 quarts of strike water at 162F. My last three batches have all overshot their mash in temps by 3 degrees, and I'd rather be under on this one that over, so we will shoot for a 159F mash in temp to get to 152F and let it mash for 75 minutes.

And after about 5 minutes of stirring we hit 152 and cover it up.

I stir from the middle to the edge of the pot and lift my paddle up the edges to the brim\and make my way 360 degrees around the pot. Doughballs come up the side pretty easily and a few times around the cycle you'll see them completely disappear. I put the thermometer probe through a binder clip attached to the basket handle. A big plus for using the basket is clipping to the handle to get a good angle to the wort.

A word about the grain. I have a barley mill and it's been set to the same setting for years. It's pretty middle of the road and cracks all of the husks. I could go finer, but it works, and my 18V drill needs a newly charged battery to power through it now, so I haven't messed with adjusting it. Plus I still have a 10 gallon cooler setup and don't want to have to adjust it back.

I've also had grain crushed at the my LHBS and they do a nice job as well. I love having the barley crusher, but it is not a mandatory piece.

And it's now after noon, so that means:

After 45 minutes our mash temp has dropped to 143, so I fire up the pot for 5 minutes and stirring pretty constantly get it up to 148.

TBC.......

Last edited: