- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

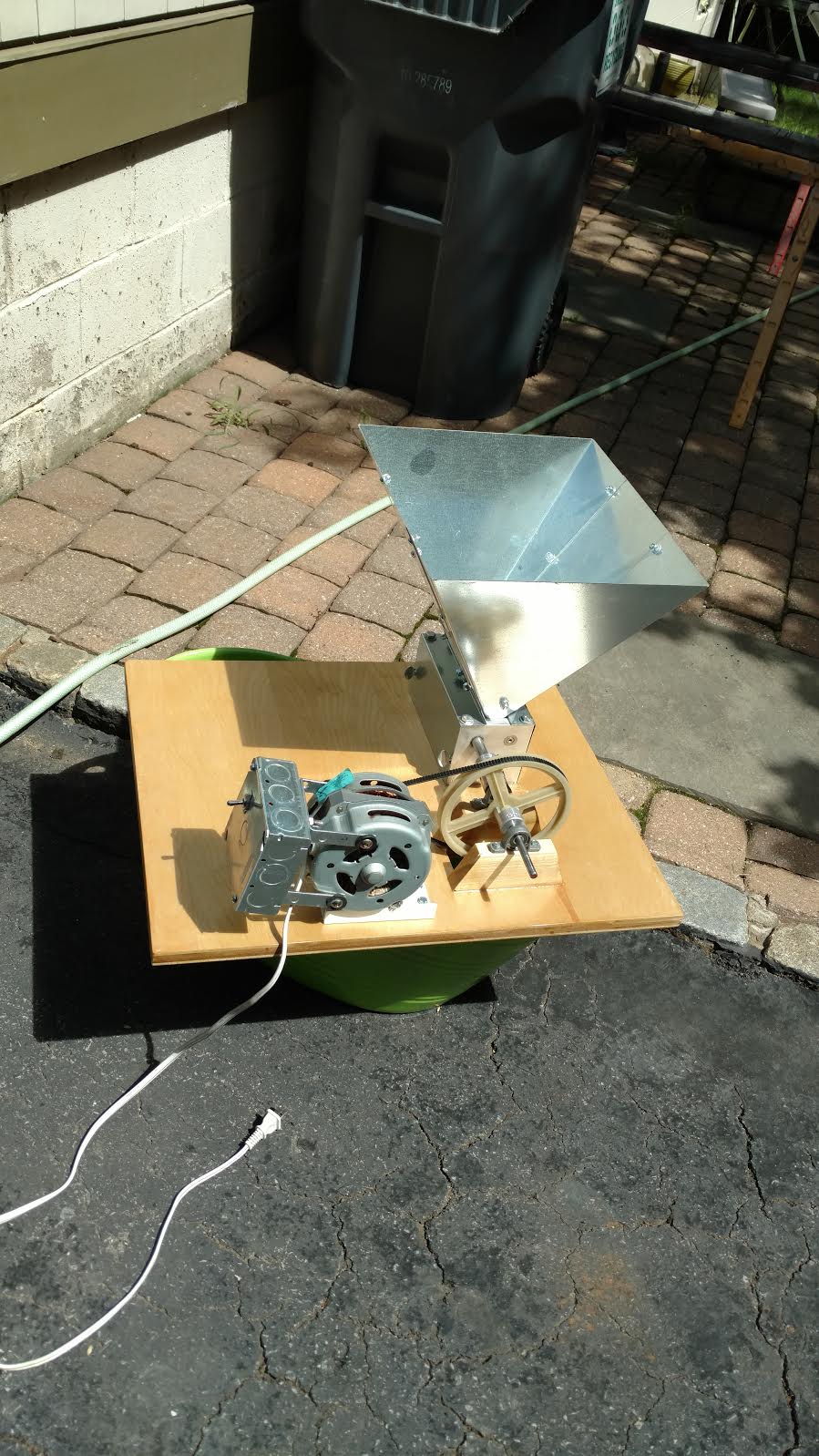

This past weekend, I finally put together my motorized grain mill. I bought the Cereal Killer mill about a year ago (very happy with it btw) and up until now, I've been either hand-cranking (ugh!) or hovering over the bucket+mill wielding a cordless drill (very functional, but a pain in the knees).

I've been trolling many threads here on HBT looking for ideas and inspiration to finally getting my mill motorized. many, many thanks to all those who came before me. Fantastic ingenuity and a will to help others is one of the best things about this forum.

I feel like the stars aligned for me on this build. I was browsing ebay, looking for "cheap motors", when I came across motors and parts for bread machines. I thought to myself "hmm, bread machines need quite a bit of torque to be able to knead dough prior to cooking it.. that should be plenty to mill grain, I wonder how I can use one of those."

What I finally settled on, was this:

Welbilt ABM2200T Bread Machine 120V 60 Hz Motor

and

Welbilt Bread Maker Machine ABM-100-3 TIMING BELT & Gear

(both $30 -- shipped)

I figured I could mount the motor/gear assembly and use a lovejoy coupler to mount it to my mill's shaft or "something".

when the parts finally arrived, my plans changed.

The gear/belt assembly is basically a bearing plate (gasketted on the face to keep bread out of the bearing) with a shaft lightly press-fit through the bearing. C-Clips are used to keep the shaft from moving much and to help provide spacing for the Gear. The gear is slid on the shaft. There is then a slotted metal plate that fits into the square recess on the gear and also mates with a slotted section on the main shaft. This metal plate is what allows the gear to transfer motion to the shaft (which ultimately turns the kneading thing in the bread maker)

This is where the stars started to align for me. the Shaft that the gear was on, looked awfully close to the same size as my Cereal Killer's shaft. and in fact, after disassembling the gear I found that they were exactly the same size (I know, I know I could have used a micrometer.. if I had one), even further than that, the little metal plate slipped onto the mill's shaft/groove perfectly.

(placing the gear on the Cereal Killer shaft)

(placing the metal clip on the Cereal Killer shaft)

(adjusting the gear and clip on the Serial Killer shaft so that the clip is in the rectangle recess and held against the lip on the end of the slot/shaft)

(wrapping electrical tape around the shaft in back of the gear -- to keep the gear from sliding back on the shaft. this will likely need to be changed in the future to a C-clip or something more stout than electrical tape)

The rest of the build is pretty basic..

I cut up the top of an old microwave cart to allow the mill, and motor to be bolted down.

wired up a simple light switch to the motor.

I've been trolling many threads here on HBT looking for ideas and inspiration to finally getting my mill motorized. many, many thanks to all those who came before me. Fantastic ingenuity and a will to help others is one of the best things about this forum.

I feel like the stars aligned for me on this build. I was browsing ebay, looking for "cheap motors", when I came across motors and parts for bread machines. I thought to myself "hmm, bread machines need quite a bit of torque to be able to knead dough prior to cooking it.. that should be plenty to mill grain, I wonder how I can use one of those."

What I finally settled on, was this:

Welbilt ABM2200T Bread Machine 120V 60 Hz Motor

and

Welbilt Bread Maker Machine ABM-100-3 TIMING BELT & Gear

(both $30 -- shipped)

I figured I could mount the motor/gear assembly and use a lovejoy coupler to mount it to my mill's shaft or "something".

when the parts finally arrived, my plans changed.

The gear/belt assembly is basically a bearing plate (gasketted on the face to keep bread out of the bearing) with a shaft lightly press-fit through the bearing. C-Clips are used to keep the shaft from moving much and to help provide spacing for the Gear. The gear is slid on the shaft. There is then a slotted metal plate that fits into the square recess on the gear and also mates with a slotted section on the main shaft. This metal plate is what allows the gear to transfer motion to the shaft (which ultimately turns the kneading thing in the bread maker)

This is where the stars started to align for me. the Shaft that the gear was on, looked awfully close to the same size as my Cereal Killer's shaft. and in fact, after disassembling the gear I found that they were exactly the same size (I know, I know I could have used a micrometer.. if I had one), even further than that, the little metal plate slipped onto the mill's shaft/groove perfectly.

(placing the gear on the Cereal Killer shaft)

(placing the metal clip on the Cereal Killer shaft)

(adjusting the gear and clip on the Serial Killer shaft so that the clip is in the rectangle recess and held against the lip on the end of the slot/shaft)

(wrapping electrical tape around the shaft in back of the gear -- to keep the gear from sliding back on the shaft. this will likely need to be changed in the future to a C-clip or something more stout than electrical tape)

The rest of the build is pretty basic..

I cut up the top of an old microwave cart to allow the mill, and motor to be bolted down.

wired up a simple light switch to the motor.

Last edited: