dzlater

Well-Known Member

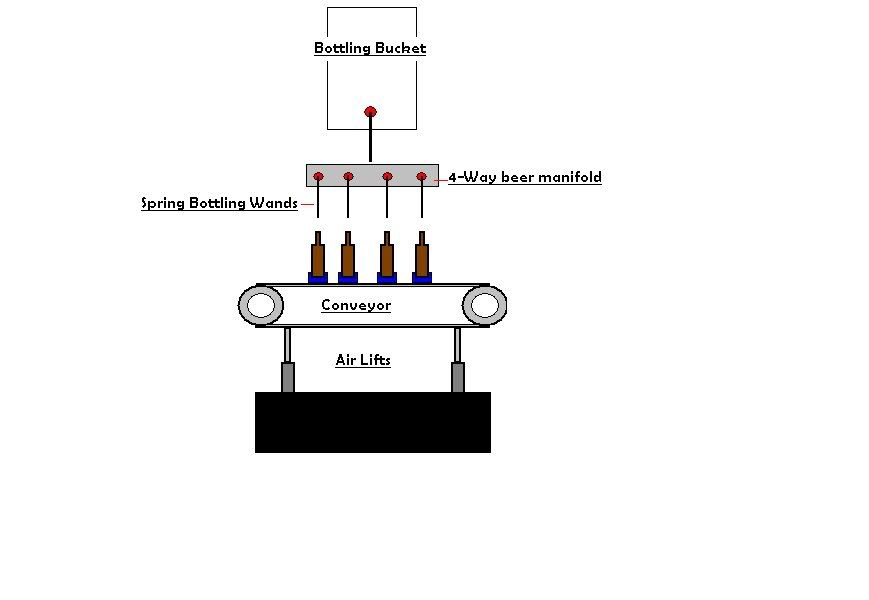

Theory of Operation

1. Use Proximity Sensors to stop conveyor when bottles are aligned under Bottling wands.

2. Air Lifts then lift conveyor table up to pre-determined height to allow bottling wands to begin dispensing beer

3. A set of contacts placed on a determined Height of one of the bottling wandswould give continuity when the beer reaches that level. These contacts closing will trigger the conveyor to begin lowering via the airlifts, stopping the flow of beer.

4. Another Proximity Sensor will determine when the conveyor is parked at its low position. Beginning the conveyor to cycle in the next 4 empty bottles and repeat the process.

5. You would need some sort of bottle catcher that would allow the bottles to slide to a capping area (manual station or another automated machine) to catch the full bottles. Or manually unload the while the next four are filling.

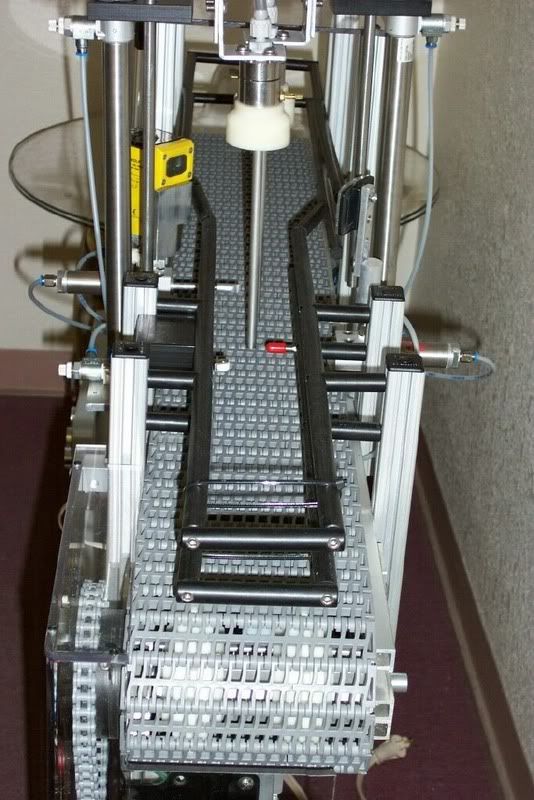

*There are cups on the conveyor that hold bottles for consistent alignment.

*All tubing from bottling bucket to manifold and manifold to bottling wands is solid tubing as to not allow any flexing.

*PLC Controlled

* This design would require consistency in bottles. ie All SA's, All Sierra Nevadas, ect

Most of this could be made from hardware store/locally available stuff.

A simple DC motor to turn conveyor

Rocker switches from radio shack

You supply the PLC or Arduino or whatever you have from control

I'll like to make this now just to see if I can........

My thought was similar but not quite as automated. ( I have no clue what a proximity sensor is )

Instead of a conveyor belt just have a tray set in a track that you could manually manually slide under the bottling wand manifold.

Lower the wands instead of raising the bottles, and fill. The slide rack of full bottles under a series if bench cappers that have their handles linked together. Then using an actuator or manually cap all the bottles at once. Does that make any sense ?