Travis H

Active Member

Looking to get back into doing some brewing again. Just wondering 3 vessel or BIAB system. Is there any real benefit to the 3vessel systems?

Biggest down side to BIAB is having to lift the bag/basket. If you have a spot for a pulley it's a non-issue.Looking to get back into doing some brewing again. Just wondering 3 vessel or BIAB system. Is there any real benefit to the 3vessel systems?

I am looking to do mostly 5-7 gallon batches. But maybe a few 12 gallon batchesBiggest down side to BIAB is having to lift the bag/basket. If you have a spot for a pulley it's a non-issue.

For the space and cost savings of AIO, 3 vessel is becoming uncommon. People do love their 3-vessel systesm, though.

What kind of budget are you on? For 5 gallon <$1000, the anvil/brewzilla are good. Bobby at brewhardware.com has a neat setup more in the <$1500 range that's worth taking a look at. (You need a pump and controller.)

I use a little 120V brewzilla. The time to boil isn't great, but otherwise I'm enjoying it vs my old setups. Kegland has a lot of neat accessories like a bluetooth thermometer.

If you have a 6/8ft ladder you hook your pulley to that over your boil kettle.Biggest down side to BIAB is having to lift the bag/basket. If you have a spot for a pulley it's a non-issue

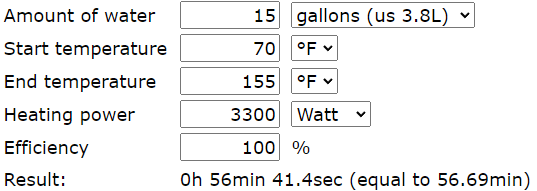

I also have the Brewzilla 120v and was not happy with the time to boil. My latest addition was one of the Hotrod Heat Sticks that Bobby sells at brewhardware.com. I throw it in when I get ready to boil and it cuts my ramp time to about 1/3 of what it was before. (from 30-45 min down to about 10-15 min). You can also use it for initial mash ramp up. Well worth the cost IMHO.I use a little 120V brewzilla. The time to boil isn't great, but otherwise I'm enjoying it vs my old setups.

I wouldn’t be put off by lack of 220v power supply. Once at mash and boil, a 110v system is going to be just as fine. Ramping up temperature is just going to take longer. No big deal breaker. Just time management.Only issue I have on going to an electric system is I live in a rental and I am not wanting to spend the money to run a 220 plug out to the garage. I have looked at them several times and would really like to go with a system like that but I just cant bring myself to spend the money on that electrical work to be able to use it

Do you have a 220 volt outlet anywhere? How far is it from the garage? You can buy or make an extension cord.I live in a rental and I am not wanting to spend the money to run a 220 plug out to the garage.

No 220 in the house at all that I have found. When moving in I even looked all around for oneDo you have a 220 volt outlet anywhere? How far is it from the garage? You can buy or make an extension cord.

No dryer? OK. Then maybe look at a dual voltage AIO and use a heat stick to supplement the element until you move?No 220 in the house at all that I have found.

Dryer is gasNo dryer? OK. Then maybe look at a dual voltage AIO and use a heat stick to supplement the element until you move?

Efficiency will certainly drop with an AIO, no sparge setup (68% BE for me). I too had issues with a stuck mash but no longer. The solution for me was to LET THE MASH SETTLE (after mixing) undisturbed for 10 minutes or so before recirculating. Once you do begin the recirculation, open the valve SLOWLY and maintain a relatively low volume flow. This will avoid creating a vacuum that will quickly compact the mash bed. I also add any flaked adjuncts separately and on top of the mash. I no longer need to use rice hulls, even on the thickest of NEIPA's.I went from a 3 vessel to an AIO and I am struggling with efficiency issues and stuck mashes which I never really suffered with on the 3 vessel system. Growing pains I know. I am currently running a Spike solo with 220V. Not a lot of commercial propane AOI's out there that I have seen, but I am sure they exist.

I have been toying with the idea of getting one of those. I have a 220 plug in the garage already that I think is still hooked up and the ease and knocking down a few hours on my brew day is enticing, but to be honest, I have not pulled the trigger yet simply because I like being a bit more involved. But, with that said, those AIO units look pretty darn cool.I couldn't imagine going back to propane after buying my Anvil Foundry. BIAB - no sparge, minimal cleanup. Not worrying about propane and all the space everything takes up. I can knock out a brew in 3.5 hours and don't have to babysit anything. I shudder looking back at missing a mash temp on propane and having to heat up some boiling water hoping I can adjust properly the first time. Nightmare. Now I just press a button and go sit back down.

They do look great and I like that its a lot easier to setup and control the temps for things. I am looking to start doing some 10-12 gallon batches. In the past I have done mostly 5 gallon batches, and brew day was only about 4 hours or so to do when using propan.I have been toying with the idea of getting one of those. I have a 220 plug in the garage already that I think is still hooked up and the ease and knocking down a few hours on my brew day is enticing, but to be honest, I have not pulled the trigger yet simply because I like being a bit more involved. But, with that said, those AIO units look pretty darn cool.

You are able to do a brew day with a propane burner and a kettle in only 4 hours? Wow, my day from start finish including cleanup is in the 5 to 7 hours, but I will admit, I am not the fastest and as the beer pours it tends to slow me down even more. LOLThey do look great and I like that its a lot easier to setup and control the temps for things. I am looking to start doing some 10-12 gallon batches. In the past I have done mostly 5 gallon batches, and brew day was only about 4 hours or so to do when using propan.

Get a 15 gallon kettle and BIAB. I can do 12 gal batches with sparging and fermcap. Much easier to clean 1 pot vs 3. And my efficiency doesn't suffer like when using an AIO system.They do look great and I like that its a lot easier to setup and control the temps for things. I am looking to start doing some 10-12 gallon batches. In the past I have done mostly 5 gallon batches, and brew day was only about 4 hours or so to do when using propan.

Pretty sure he does BIAB. Don't know how big his kettle is though.Get a 15 gallon kettle and BIAB.

My condo association sent out a letter forbidding open flames and propane tanks, soooo, I might be in the same boat. Electric in the garage! (But propane for now, until I get caught lol)Two things I’ve changed, in order, and couldn’t be paid to reverse.

1. Propane to electric

2. 3v to 1v BIAB.

I’m not saying it’s for everyone and I get there might be logistical issues but its been a godsend for me.

I have done mostly BIAB brewing. Mostly 3-5 gallon batches. Currently I have a basic 8 gallon kettle. I am looking at getting a 20 gallon kettle with the ports so I can hook up a pump. I am looking to be able to do 10-12 gallon batches but still do some in the 5-7 gallon batches.Pretty sure he does BIAB. Don't know how big his kettle is though.

My brew days run pretty long, but that's mostly because I'm an old fart so I take my time and also take a break whenever I can. I could probably cut it down to <5 hours if I really tried, but that's not really a goal.

No open flames??? How are you going to fix a steak or ribs?My condo association sent out a letter forbidding open flames and propane tanks, soooo, I might be in the same boat. Electric in the garage! (But propane for now, until I get caught lol)

Very sneakilyNo open flames??? How are you going to fix a steak or ribs?

Good answer!!!!!Very sneakily

I would think a smoker, gas grill, etc. wouldn't be considered open flame. Fire pit and propane burner, yes. Seems odd that they mentioned open flames and propane tanks. Makes you kind of wonder . . .No open flames??? How are you going to fix a steak or ribs?

True. A smoker an electric pellet feed smoker isnt really a true open flame, so that should be fine. But there again some of these HOA's have some of the most screwed up rules ever.I would think a smoker, gas grill, etc. wouldn't be considered open flame. Fire pit and propane burner, yes. Seems odd that they mentioned open flames and propane tanks. Makes you kind of wonder . . .

Like they've been spying on me? Mmmhmmm...I would think a smoker, gas grill, etc. wouldn't be considered open flame. Fire pit and propane burner, yes. Seems odd that they mentioned open flames and propane tanks. Makes you kind of wonder . . .

Gotta keep an eye out for THE MAN!!!!Like they've been spying on me? Mmmhmmm...

I brew ten gallon batches with a 25 gallon kettle. I'd recommend a larger kettle.I have done mostly BIAB brewing. Mostly 3-5 gallon batches. Currently I have a basic 8 gallon kettle. I am looking at getting a 20 gallon kettle with the ports so I can hook up a pump. I am looking to be able to do 10-12 gallon batches but still do some in the 5-7 gallon batches.

Yes, very important here! I brew near the kitchen so one line goes onto that circuit and the other from a separate breaker circuitBe careful with 2 x 120v elements. 3200w of heat is over the ~2000w normal load of a single outlet panel breaker. Make sure each element is plugged into its own breaker. Just a PSA

I've recently told myself to back off on these conversations because they do seem to get a little heated and everyone really wants to defend the choices they've made. I'll be restrained for now.. I couldn't agree more with these two points.Two things I’ve changed, in order, and couldn’t be paid to reverse.

1. Propane to electric

2. 3v to 1v BIAB.

I’m not saying it’s for everyone and I get there might be logistical issues but its been a godsend for me.

I have done mostly BIAB brewing. Mostly 3-5 gallon batches. Currently I have a basic 8 gallon kettle. I am looking at getting a 20 gallon kettle with the ports so I can hook up a pump. I am looking to be able to do 10-12 gallon batches but still do some in the 5-7 gallon batches.