Belgian Samurai

Well-Known Member

- Joined

- Dec 15, 2020

- Messages

- 112

- Reaction score

- 33

Ok, I know there are so many posts on this topic, some of which I've read, but I'm still trying to wrap my mind around it.

From what I've gathered, it is dependent on beer style (FG) as well keezer temp, but let's I don't want to complicate it with long mathematical equations. I heard that 36-38° is optimal for pouring beer with minimal/no foam.

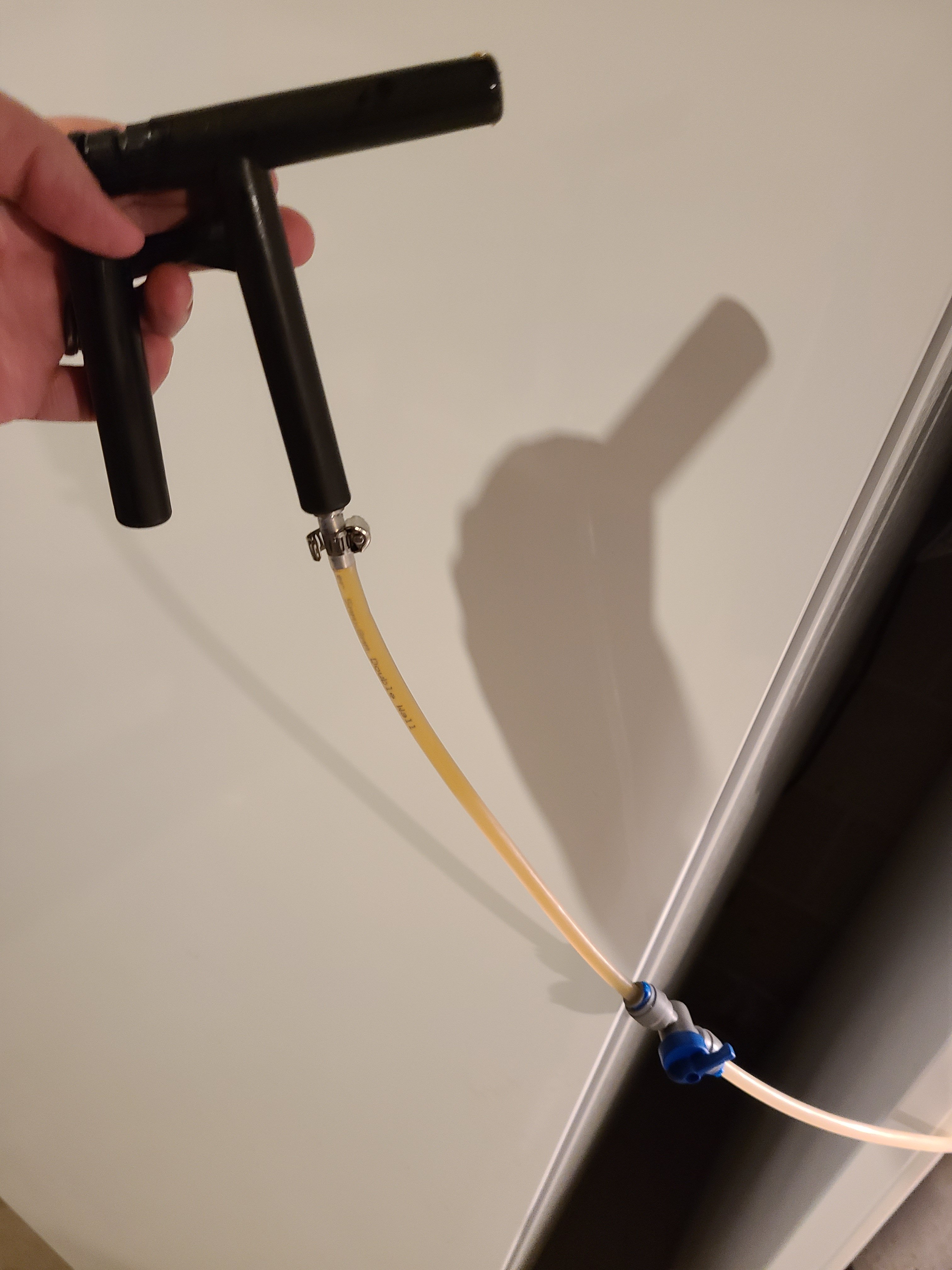

I also read that you measure distance from the back of tap to the center of the top of the keg, but as you see, that is a pretty short throw, so ... I am using 5mm EVA-Barrier tubing. How long should my line be?

As you can see, I don't even know if I'm correctly asking the question.

Thanks!

From what I've gathered, it is dependent on beer style (FG) as well keezer temp, but let's I don't want to complicate it with long mathematical equations. I heard that 36-38° is optimal for pouring beer with minimal/no foam.

I also read that you measure distance from the back of tap to the center of the top of the keg, but as you see, that is a pretty short throw, so ... I am using 5mm EVA-Barrier tubing. How long should my line be?

As you can see, I don't even know if I'm correctly asking the question.

Thanks!