This is the second part of my bar build. The actual building of the bar can be found here: https://www.homebrewtalk.com/showthread.php?t=596537

My bar is in the finished portion of my basement. On the other side of the wall is the unfinished part of my basement, which is where the keezer will be, and the faucets will be through the wall.

The faucets:

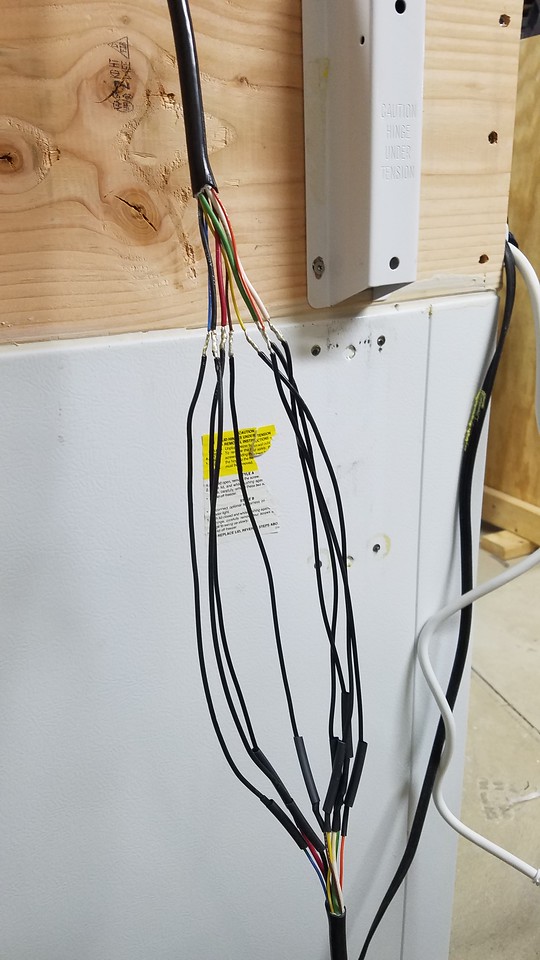

The other side of the wall

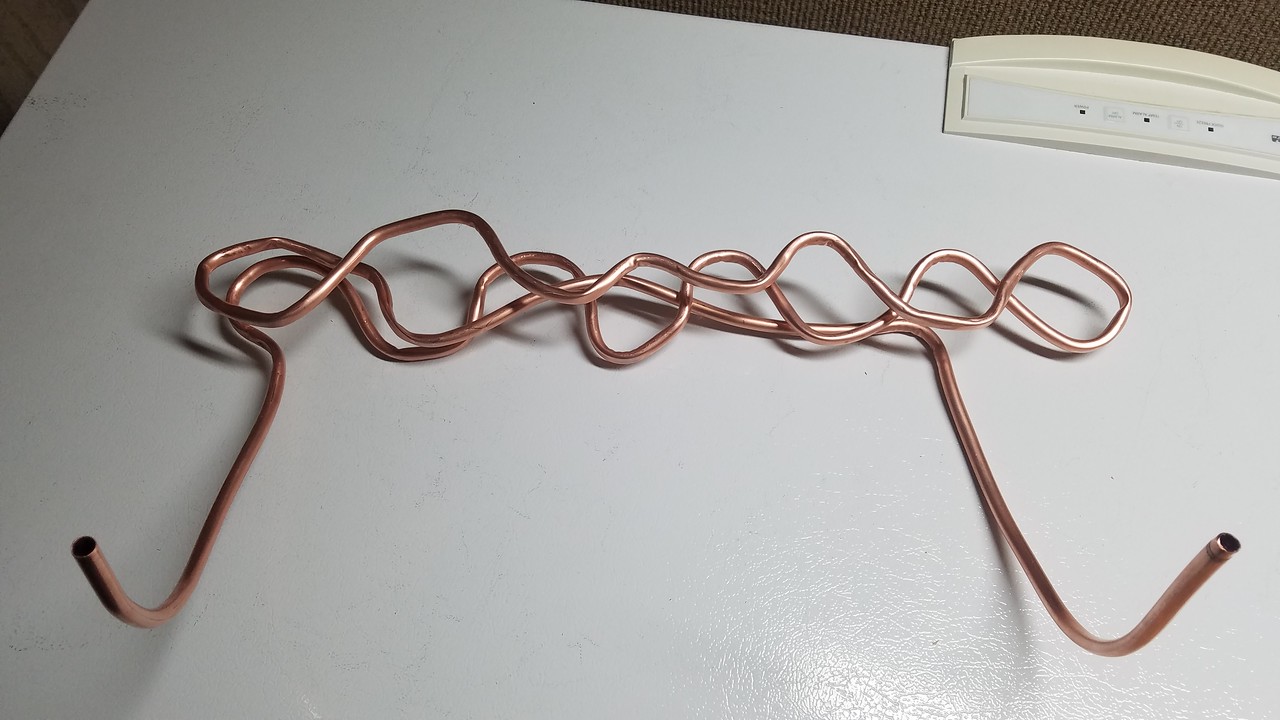

I am using a 20 cubic foot chest freezer that I will be putting a 10" collar on. I will then be using PVC tubing to connect the lines to a box I'm building around the shanks. I will be using both water and air cooling to ensure cool lines and clean first pours.

The first thing to do was to make space for the box I'm building around the back of the shanks.

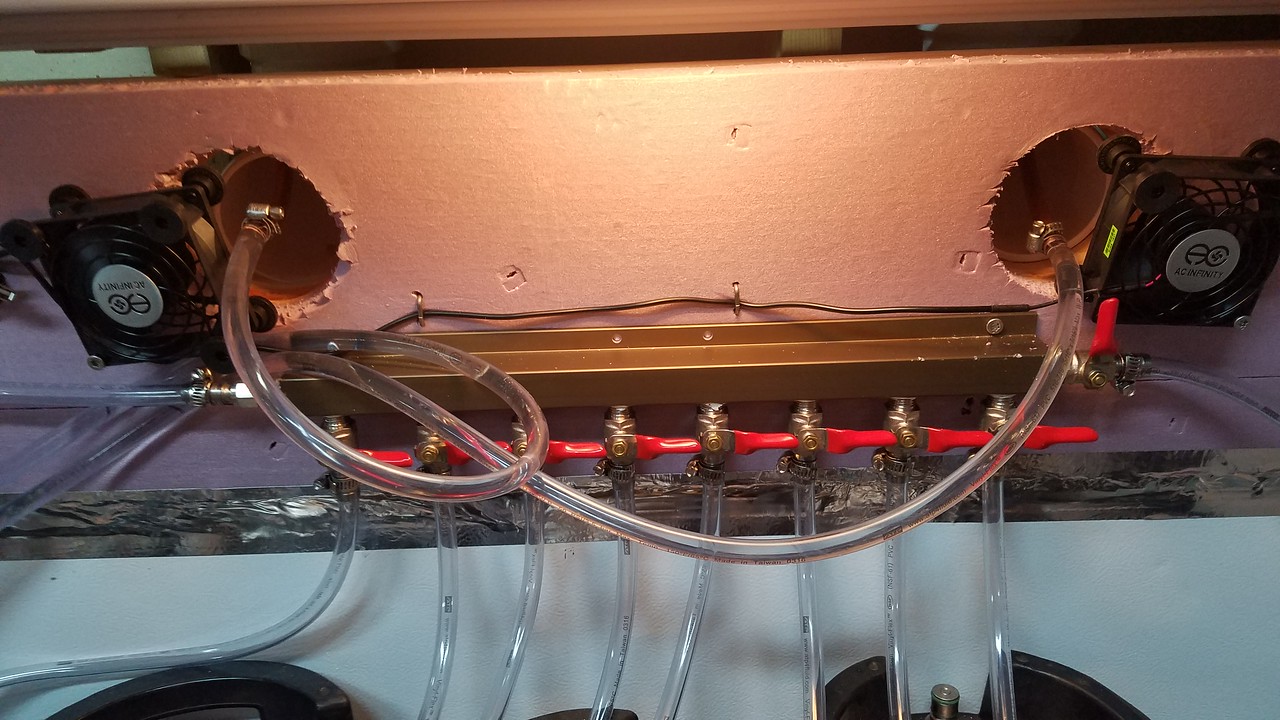

And then build the box. The box was insulated with 1" foam board insulation. I used both liquid nails and staples to hold it together. I cut out two holes for the 3" PVC pipes that are going to house the beer lines and cooling lines.

I also put a thin piece of plywood over the foam board insulation so that I could adequately tighten the shank nuts.

I then taped over everything with foil tape

I then added a door with more foam board insulation, and then covered that with the foil tape as well.

The PVC pipes and signage were added

My bar is in the finished portion of my basement. On the other side of the wall is the unfinished part of my basement, which is where the keezer will be, and the faucets will be through the wall.

The faucets:

The other side of the wall

I am using a 20 cubic foot chest freezer that I will be putting a 10" collar on. I will then be using PVC tubing to connect the lines to a box I'm building around the shanks. I will be using both water and air cooling to ensure cool lines and clean first pours.

The first thing to do was to make space for the box I'm building around the back of the shanks.

And then build the box. The box was insulated with 1" foam board insulation. I used both liquid nails and staples to hold it together. I cut out two holes for the 3" PVC pipes that are going to house the beer lines and cooling lines.

I also put a thin piece of plywood over the foam board insulation so that I could adequately tighten the shank nuts.

I then taped over everything with foil tape

I then added a door with more foam board insulation, and then covered that with the foil tape as well.

The PVC pipes and signage were added