So, I kegged up a honey citra blonde about 5 days ago. I overcarbed at 35 psi for 2 days then turned it down to 12 psi. After one day at 12 psi, the beer tasted awesome! I mean like sweet, juicy and super chug able at 7.5% ABV. I put a little honey malt in the mash and could taste it. Plus the Citra hopS gave it a nice citrus juicy finish. Awesome mouth feel and probably one of the best beers I ever made. The next day, the beer has an off flavor now, dry to the tongue and an off bitter flavor. It lost its juiciness and the sweet honey hint is all gone. Could it be my CO2 bottle? I am using a steel bottle and made a mistake several months ago. I left the valve open to the atmosphere when it was empty for several weeks. Could it have rusted and now killing the beer? I am so upset at this point. 10 gallons of beer that probably going to get dumped. All this just before a bunch of friends where coming over this weekend to try this beer I was bragging about. Anyone experience a dirty and or rust CO2 bottle before? Before I tapped these kegs i pulled and cleaned the lines with LLC and hand cleaned the taps inside and out. I also soaked and scrubbed the kegs in oxyclean and a little TSP until everything was clean and brite. That includes pulling the valves and pick up tubes and giving them a good cleaning. I have not had good luck with the last few batches and am rethinking this whole hobby.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bad CO2 Bottle?

- Thread starter bgmac

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

snarf7

Well-Known Member

- Joined

- Apr 30, 2017

- Messages

- 379

- Reaction score

- 114

I don't think that could be the cause...when a CO2 tank is refilled, all the air is forced out and replaced with CO2. I suppose a rusty valve or regulator could be responsible but I've never experienced anything like that. Definitely don't dump it, if there's one thing I've learned it's that the beer changes daily and often things that you find offputting at first will fade or mellow with time

Was thinking I will let it go flat a little but keep it under a couple of psi of CO2 to keep it from being oxygenated. I ran a new beer line in on of the kegs and shook some CO2 out of the beer and it smoothed out a little. But still has about half of the off flavor that wasn’t there a day ago. I wonder if it’s carbonic acid. Thinking let it run low in CO2 pressure and replacing the beer lines along with the CO2 bottle might make it salvageable.

snarf7

Well-Known Member

- Joined

- Apr 30, 2017

- Messages

- 379

- Reaction score

- 114

Was thinking I will let it go flat a little but keep it under a couple of psi of CO2 to keep it from being oxygenated. I ran a new beer line in on of the kegs and shook some CO2 out of the beer and it smoothed out a little. But still has about half of the off flavor that wasn’t there a day ago. I wonder if it’s carbonic acid. Thinking let it run low in CO2 pressure and replacing the beer lines along with the CO2 bottle might make it salvageable.

Definitely worth a shot

GoeHaarden

The best advice is unsolicited

- Joined

- Feb 1, 2017

- Messages

- 1,328

- Reaction score

- 739

Was thinking I will let it go flat a little but keep it under a couple of psi of CO2 to keep it from being oxygenated. I ran a new beer line in on of the kegs and shook some CO2 out of the beer and it smoothed out a little. But still has about half of the off flavor that wasn’t there a day ago. I wonder if it’s carbonic acid. Thinking let it run low in CO2 pressure and replacing the beer lines along with the CO2 bottle might make it salvageable.

This! I bet you over carb'd and you're tasting that carbonic acid bite. I always just hook my kegs up to serving pressure and let it ride, but two days of high pressure seems a bit long. I always thought it was more like 36 hours at 35psi. I've never had an issue this way. I'd say pull it out to room temp, and pull your prv every so often. Once flat, then try again...setting to serving pressure seems, to me, like the easiest way to get the desired carbonation.

Feeling better. I pulled the kegs out of the fridge yesterday and took it off the CO2. I shook them a few times and relieved the pressure down till it was maybe a couple of pounds. After about 18 hours I put them back in the fridge still off the CO2. Thinking the warmer temps out of the fridge would speed up the CO2 release. I released the pressure to near zero a few times after they warmed up also. I let them cool for a few hours and took a taste. Now it just tastes like typical 3 and a half week green beer. Maybe just the slightest hint of the off taste from before but you really have to pay attention to notice it. Not as good as it was the first day but way better then it was yesterday. Today I ordered new serving lines and gas lines (even though I know they are clean with my LLC pump cleaner system I just used 4 days ago. Tomorrow I am going to swap the CO2 bottle at the local brew store an then set the CO2 level low, maybe 6 or 7 and see what happens after a day or two. It tastes better but lost the nice honey malt sweet hint it had on the first try. Maybe it was over carbed and or bad CO2? I will find out with a fresh gas bottle tomorrow.

how are you transfering the beer from the fermenter to the keg?

Follow up: After shocking all the old steel bottle CO2 out of the beer and recarbing on a new clean bottle, the beer turned out awesome! The off flavor was completely in the CO2. At 5 plus weeks, the beer has dropped 100% clear and has the slight sweet honey aftertaste I was looking for. Too bad there isn't much left. Friends preferred my beer over their craft macro bottled beer they brought over. Lesson learned, don't leave a CO2 bottle valve open when empty, especially if its steel. Probably rusted inside from humidity etc.

Even if it were rusted rust does not outgas and it has no smell whatsoever. Besides that, if your bottle complies with current food regs it should have a valve that will not relase the last few pounds of pressure even if you leave the shut-off valve completely open (although I realize as I'm writing that this might not be the case in your particular jurisdiction), this is to prevent air from getting in and getting mixed with the CO2 from the next recharge.

Whatever off-flavor you were detecting was probably due to the beer being too green and needing longer conditioning times.

Whatever off-flavor you were detecting was probably due to the beer being too green and needing longer conditioning times.

I am 100% positive it came from the CO2. Before I got a new CO2 bottle, I let a pint go flat and the off flavor was gone. All I know is that the steel bottle will be swapped for a new/re-certified bottle when I get a chance to run over to the local welding supply store.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

I'm with you. I don't like steel bottles I get from my local gas source. Twice they have told me they are out of aluminum 5lb bottles. I typically only use aluminum. These two times the beer got a fowl taste when I switched gas bottles. Now I refuse to take a steel bottle. I own two aluminum, so I always have a back up and never a need to take a steel bottle I can wait a few days for my local source to get aluminum empties.I am 100% positive it came from the CO2. Before I got a new CO2 bottle, I let a pint go flat and the off flavor was gone. All I know is that the steel bottle will be swapped for a new/re-certified bottle when I get a chance to run over to the local welding supply store.

The taste is an aweful taste like dimethyl sulfide or vegetable. I think of split peas soup. I've had beers I made for football tailgating. They were aweful on this CO2 gas in steel, good thing was I was the only person who could detect it taste wise. People thought I was being too critical of my own beer.

I'm with you. I don't like steel bottles I get from my local gas source. Twice they have told me they are out of aluminum 5lb bottles. I typically only use aluminum. These two times the beer got a fowl taste when I switched gas bottles. Now I refuse to take a steel bottle. I own two aluminum, so I always have a back up and never a need to take a steel bottle I can wait a few days for my local source to get aluminum empties.

The taste is an aweful taste like dimethyl sulfide or vegetable. I think of split peas soup. I've had beers I made for football tailgating. They were aweful on this CO2 gas in steel, good thing was I was the only person who could detect it taste wise. People thought I was being too critical of my own beer.

I agree with you. Going to try and find a place to swap the steel bottle for an aluminum bottle. I wont trust steel from now on.

Mic Carp

Loud Mic

I'm with you. I don't like steel bottles I get from my local gas source. Twice they have told me they are out of aluminum 5lb bottles. I typically only use aluminum. These two times the beer got a fowl taste when I switched gas bottles. Now I refuse to take a steel bottle. I own two aluminum, so I always have a back up and never a need to take a steel bottle I can wait a few days for my local source to get aluminum empties.

The taste is an aweful taste like dimethyl sulfide or vegetable. I think of split peas soup. I've had beers I made for football tailgating. They were aweful on this CO2 gas in steel, good thing was I was the only person who could detect it taste wise. People thought I was being too critical of my own beer.

I too have 2 5lb bottles and a 10lb for charging. If they don't have a new aluminum bottle at refil time, i just tell them to gimme a call when they get more in.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Not to over state the obvious. Maybe it's not the bottle but the gas in the bottle.Just what we need, a new homebrew myth, "steel gas contamination".

Do you know the difference between food grade CO2 and standard? I do not.

Maybe coincidentally the standard is in steel and the food grade in aluminum.

Robert65

Major Obvious (recently promoted)

As I recall, the fundamental requirement for food grade CO2 as opposed to industrial is that it be free of traces of mineral oils from lubrication. That leaves a lot of room for other impurities.Not to over state the obvious. Maybe it's not the bottle but the gas in the bottle.

Do you know the difference between food grade CO2 and standard? I do not.

Maybe coincidentally the standard is in steel and the food grade in aluminum.

Oh oh oh!!As I recall, the fundamental requirement for food grade CO2 as opposed to industrial is that it be free of traces of mineral oils from lubrication. That leaves a lot of room for other impurities.

Can i get in on this?!?

Lol.

To the OP- try looking for an Airgas or similar. They dont usually fill on site but only carry "food grade" co2. I used to get my shiny new bottle filled at a fire extinigusher place or a welding shop... but just ended up swapping for a prefilled one.

I have read countless posts on here on regular vs. foodgrade.. (search. So many!!).

I would agree most of us could not tell the difference. But why not just get the good stuff anyway?

Robert65

Major Obvious (recently promoted)

Yes, Airgas is a good source. I get mine exchanged at LHBS, but they get it from Airgas, saving me some time and distance.

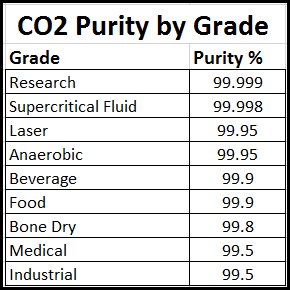

Everything we get is likely food grade in that it is free of compressor lubricants. But beyond that there are other grades of purity. Most of what we get is 99.9% CO2. There are medical and research grades that can add a 9 or two, and "pure" or "beverage grade" can mean just 99.0%. A significant portion of the impurity will be oxygen. There can also be some moisture. This may be insignificant, but I could see it, over time, corroding steel. A very, very long time.

So go with Airgas (you can go to their website for specs on their gases, but IIRC the standard stuff is at least 99.9%) and use aluminum bottles and you should rest easy.

Everything we get is likely food grade in that it is free of compressor lubricants. But beyond that there are other grades of purity. Most of what we get is 99.9% CO2. There are medical and research grades that can add a 9 or two, and "pure" or "beverage grade" can mean just 99.0%. A significant portion of the impurity will be oxygen. There can also be some moisture. This may be insignificant, but I could see it, over time, corroding steel. A very, very long time.

So go with Airgas (you can go to their website for specs on their gases, but IIRC the standard stuff is at least 99.9%) and use aluminum bottles and you should rest easy.

Robert65

Major Obvious (recently promoted)

Not sure about Airgas directly, as I assume my LHBS is including a markup, but they currently charge $16 for a fill or exchange of a 5 lb bottle. I should note this may not reflect Airgas retail, because LHBS buys large tanks and fills 5-20 lb bottles on premises.

Sacramento ca i pay $20 +$2 taxes for 5#Curious what you guys are paying for CO2 at Airgas

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

I pay $18 for 5 lbs. Central Illinois. I get it from Airgas

Sacramento ca i pay $20 +$2 taxes for 5#

Hah, man we get screwed in Sacramento. Thats not bad. I’m paying $24 at the fire extinguisher supply place, and they re-cert bottles. Having a hard time letting go of my nice, shiny alum CO2 bottle for trade. I think the LHBS just does tradeouts as well via Prax

Dude... let it go!!! Lol. Once i did life got WAY easier!Hah, man we get screwed in Sacramento. Thats not bad. I’m paying $24 at the fire extinguisher supply place, and they re-cert bottles. Having a hard time letting go of my nice, shiny alum CO2 bottle for trade. I think the LHBS just does tradeouts as well via Prax

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

I had that problem at first. Thank God I got over it quickly.Dude... let it go!!! Lol. Once i did life got WAY easier!

I don't like to have lots of beer, be alone in an empty house, have nothing to do, and be stranded in a state of sobriety.

Seriously... i was just @ airgas last week... my exchange got me a brand new, cream colored top.5# tank.. it looks soooo good! But you know what? It goes inside the keezer and does it's thing. Nobody sees it. When it is empty i will just swap it. They guys at the shop and i were laughing about how i used to care... i would even drive farther for a fill vs. a swapI had the problem at first. Thank God I got over it quickly.

I don't like to have lots of beer, be alone in an empty house, have nothing to do, and be stranded in a state of sobriety.

So stupid!!

Oh, cause i just learned them:

:bottle:

Robert65

Major Obvious (recently promoted)

I think the LHBS just does tradeouts as well via Prax

Praxair is on a par with Airgas if it's more accessible. Specs also available on website.

And having the same gas filled in a different bottle is going to fix the issue how?Not to over state the obvious. Maybe it's not the bottle but the gas in the bottle.

Do you know the difference between food grade CO2 and standard? I do not.

I do. It's the traceability requirements and the liability issue. The gas itself is the same. There are no lubricants in CO2, either food grade or industrial.

Maybe coincidentally the standard is in steel and the food grade in aluminum.

Now you're just making stuff up. I assure you I get food grade CO2 filled in a steel cylinder with all the associated paperwork on a regular basis. No metal (either rusted or not) will release vapors at temperatures at which life is still possible. You cannot "smell" metal.

It has to be free of anything that could be harmful to humans. Other than that it's only traceability and liability issues.As I recall, the fundamental requirement for food grade CO2 as opposed to industrial is that it be free of traces of mineral oils from lubrication. That leaves a lot of room for other impurities.

If you buy industrial CO2, use it for food processing and somebody gets sick you're the only one liable for it as the CO2 was not intended for that purpose, so it's entirely your fault.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

And having the same gas filled in a different bottle is going to fix the issue how?

I do. It's the traceability requirements and the liability issue. The gas itself is the same. There are no lubricants in CO2, either food grade or industrial.

Now you're just making stuff up. I assure you I get food grade CO2 filled in a steel cylinder with all the associated paperwork on a regular basis. No metal (either rusted or not) will release vapors at temperatures at which life is still possible. You cannot "smell" metal.

I'm not trying to debate you.

I didn't disagree with your previous post. That the metal doesn't make a difference. Only that it has a distinguished visual difference aluminium vs steel and then the taste itself. I'm not advocating cause and effect with the metal type. Only that there is a visual, metal type, and a perceived taste difference.

All I know the gas bottle changed how the beer tasted. I'm looking for an explanation. As does the OP.

What do think is the root cause? The gas or something else?

Sorry if I misinterpreted your post. As the majority position here seems to be that the metal is the cause for the off-flavor I took your posts to be in agreement with the majority consesus.

Personally, I think the likelihood that the off-flavor stems from CO2 contamination is not higher than 0,1%, whereas the likelihood that the cause lies in the brewing process is around 99,99%. The reason being that in 99,99% of cases even if you don't buy food grade CO2 you're still getting food grade CO2, you just don't get the associated paperwork. At the manufacturing level there is no difference between food-grade and non food-grade and certainly no one goes around contaminating non food-grade CO2 on purpose.

Personally, I think the likelihood that the off-flavor stems from CO2 contamination is not higher than 0,1%, whereas the likelihood that the cause lies in the brewing process is around 99,99%. The reason being that in 99,99% of cases even if you don't buy food grade CO2 you're still getting food grade CO2, you just don't get the associated paperwork. At the manufacturing level there is no difference between food-grade and non food-grade and certainly no one goes around contaminating non food-grade CO2 on purpose.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Sorry if I misinterpreted your post. As the majority position here seems to be that the metal is the cause for the off-flavor I took your posts to be in agreement with the majority consesus.

Personally, I think the likelihood that the off-flavor stems from CO2 contamination is not higher than 0,1%, whereas the likelihood that the cause lies in the brewing process is around 99,99%. The reason being that in 99,99% of cases even if you don't buy food grade CO2 you're still getting food grade CO2, you just don't get the associated paperwork. At the manufacturing level there is no difference between food-grade and non food-grade and certainly no one goes around contaminating non food-grade CO2 on purpose.

Ok. Much to think about...

I'm brewing according to LOB. All prior experience with gas and bottle types was before persuing LOB. I try to spund or to naturally carbonate. I'm using a fraction of the gas I used before. Since then I've had little to no problems using only aluminum bottles. That said, I'm not a staunch advocate on one factor at a time analysis.

I'd be interested in your brewing practices and how it compares to people's hypothesis on gas and your experiences.

Last edited:

In any case, if in the OP's or your case water really did somehow migrate into the empty CO2 bottle then the main issue with that would be bacterial or fungal proliferation, which might indeed be causing unwanted aromas in subsequent refills. That's why modern regulations in many countries (not sure about the USA) mandate the use of residual valves in bottles that are meant to contain food-grade gases. A residual valve will always maintain a minimum residual positive pressure in the bottle thus always preventing contamination from outside sources.

If that is what is causing the issue then it really doesn't matter whether it's an aluminum or a steel bottle, contamination will cause issues in both cases. If you were experiencing that then replacing the bottle with another steel bottle would have fixed the issue just the same, but since either accidentally or on purpose you got a bottle made of a different material it's easy to give in to the temptation of seeing a causal correlation where there can be none.

If that is what is causing the issue then it really doesn't matter whether it's an aluminum or a steel bottle, contamination will cause issues in both cases. If you were experiencing that then replacing the bottle with another steel bottle would have fixed the issue just the same, but since either accidentally or on purpose you got a bottle made of a different material it's easy to give in to the temptation of seeing a causal correlation where there can be none.

Last edited:

brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,739

- Reaction score

- 2,508

I’ll add most of those threads end with a call to the gas company who says something like “we just stock food grade. Everybody gets the same stuff because it’s easier to stock one vs two grades.” There’s usually a caveat that goes something like “we sell to all the restaurants and welding supply houses in this area. Everyone gets the same gas.”

This is what I have read on every thread about CO2 here. Also, I think the same probably goes for the welding supply and fire extinguisher shops as well.I’ll add most of those threads end with a call to the gas company who says something like “we just stock food grade. Everybody gets the same stuff because it’s easier to stock one vs two grades.” There’s usually a caveat that goes something like “we sell to all the restaurants and welding supply houses in this area. Everyone gets the same gas.”

I think @Vale71 brings up a good point- it might be more about liability and supply chain than anything else. OF course, he uses a comma for a decimal, so he may not be from around here ('Murica), so I can only imagine that our snowflake laws are more strict.

And I also use metric like there's no tomorrow, so take that you 'merican...

Regs can of course change from country to country (in your case even from State to State) and be more or less stringent accordingly. Residual valves might or might not be mandatory, traceability might or might not be mandatory, filling stations might or might not have to be designed and operated so that no contamination can be dragged into the bottle during filling (which might or might not require evacuating all lines with a vacuum pump prior to commencing filling) and so on and so forth.

One principle is more or less universal though. If somebody dies (or at least gets seriously ill), somebody else might have a problem...

Regs can of course change from country to country (in your case even from State to State) and be more or less stringent accordingly. Residual valves might or might not be mandatory, traceability might or might not be mandatory, filling stations might or might not have to be designed and operated so that no contamination can be dragged into the bottle during filling (which might or might not require evacuating all lines with a vacuum pump prior to commencing filling) and so on and so forth.

One principle is more or less universal though. If somebody dies (or at least gets seriously ill), somebody else might have a problem...

Similar threads

- Replies

- 3

- Views

- 464

- Replies

- 13

- Views

- 772

- Replies

- 13

- Views

- 914