So, my first brewday on the Anvil is ongoing right now, I'm halfway through the mash. So far everything is going fine (in regards to the Foundry, anyway... I had a couple f-ups that were 100% on me LOL).

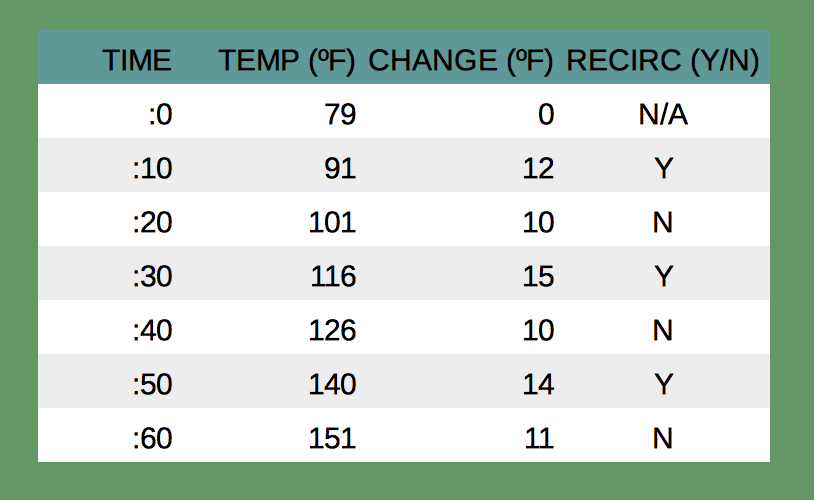

As I heated up my strike water I decided to test recirculating vs. not, and found that recirculating (tubing cut precisely to length, and the lid clamped on the entire time) did increase heatup rates by a bit.

Here's my data:

After 60 minutes I stopped timing and let it just go all the way to my target temp of 159ºF, while recirculating, as I milled my grain.

So for the ten minute segments where I recirculated, I did see an increase in temperature gain... enough that I plan to recirculate the entire time next session, as it looks like it would save me at least 10 - 15 minutes heating to strike temp.

(I would not, of course, recirculate if I was setting the timer the night before...)

It's recirculating now for the mash, and so far this little pump is performing admirably. It's virtually silent, no cavitation issues, and if I let it go full-steam it's quite powerful -- not quite as fast as my Chugger or March pumps, but close enough for brewing purposes.

Update #1: Just finished the mash, and I hit an efficiency of 76%. Can't complain at that!

Lifted the malt pipe, took about four minutes for the primary wort to drain, I'm going to let it sit at least until the wort comes up to a boil, if not longer.

Update #2: Took just shy of an hour to bring ~6 gallons to a boil @ 120v. It's a very gentle boil; when I first took the lid off it looks a bit more vigorous, but it settled down to more a "simmer". Not unexpected, just posting the deets. (It is interesting that the readout says 208ºF, but it's clearly at a very low "entry level" boil.)

My hop tube only reaches a couple of inches into the wort, so I unhooked it from the side of the Foundry and set it on the bottom. Had about 0.5" clearance, but that was enough. Might not be next time, I'll have to be careful... might have to look for a mesh tube that is taller than 14"...

Cracked open a Maine Beer Zoe to have with my lunch.

Update #3: Chilling. I'm immediately thinking to install an

SSBrewTech whirlpool fitting on the Anvil. I have one on my regular boil kettle and it works like a champ. AFAIK there are no electrical components / wiring in the walls of the Anvil, but I'll check w/ them to be sure. Also would need to be sure there is enough clearance to allow the whirlpool fitting to co-exist with the malt tube. If not I'll have to look into one of the hang-over-the-side types...

Update #4: Cleaning the malt pipe in the kitchen is a bit challenging; my normal process for cleaning pots and kettles is to set them sideways over the sink, angled down a little bit, and use my sprayer to rinse out the residual trub, grains, etc. from the inside. Doesn't work that well w/ the malt pipe since the bottom & bottom sides are mesh. Let's just say I got some water... everywhere... LOL.

And of course I lost one of the tiny little washers for the thumbscrews that hold the pumphead on. I'll have to hit the hardware store this week to replace it... hopefully they have some that small!

Also took a moment to sample a mead that I'm getting close to racking into a keg. Dayum it's going to be a good batch! Need to add a little acidity when I go to keg, but it's really nice as it stands.

Today has been a good day.

Recipe:

Vienna Red Ale

19-A American Amber Ale

Size: 5.25 gal

Efficiency: 76.02%

Attenuation: 73%

Calories: 260.28 kcal per 16.0 fl oz

Original Gravity: 1.058 (1.045 - 1.060)

Terminal Gravity: 1.016 (1.010 - 1.015)

Color: 13.64 SRM (10.0 - 17.0)

Alcohol: 5.6% (4.5% - 6.2%)

Bitterness: 49.3 (25.0 - 40.0)

Ingredients:

11 lb (92.1%) Vienna Malt

8 oz (4.2%) Cara-Pils® Malt

3 oz (1.6%) Roasted Barley

4 oz (2.1%) Acidulated Malt

8 oz Rice Hulls

.7 oz (35.0%) Chinook (12.9%) @60 m

.7 oz (35.0%) Centennial (9.3%) @60 m

1 tsp Wyeast Nutrient @10 m

1 ea Whirlfloc Tablets (Irish moss) @10 m

1 ea Servomyces @10 m

.3 oz (15.0%) Chinook (12.9%) @0 m

.3 oz (15.0%) Centennial (9.3%) @0 m

1 ea Clarity-Ferm (10ml) - added dry to primary fermenter

1 ea Imperial A01 House

MASH WATER TARGETS

Ca 72 ppm

Mg 3 ppm

Na 8 ppm

SO4 114 ppm

Cl 59 ppm

HCO3 NA

SO4/Cl Ratio 1.9

Target Mash pH: 5.31

Mash Temp: 151ºF for 60 m