invictusbrew

Well-Known Member

- Joined

- Jun 12, 2013

- Messages

- 349

- Reaction score

- 95

Yep, that's right. Another one. I've been planning this build for about a year now... but don't let that fool you into thinking it will be any good (God, I sure hope it turns out good). My skills on this stuff are decent at best, and will probably show through, but at the end of the day even if the welds aren't so great, the paint looks like I let my 3 year old do it, and the electronics are just this side of a fire hazard, I'll feel damn proud that I built the thing myself. As ugly as she may be because of it. :rockin:

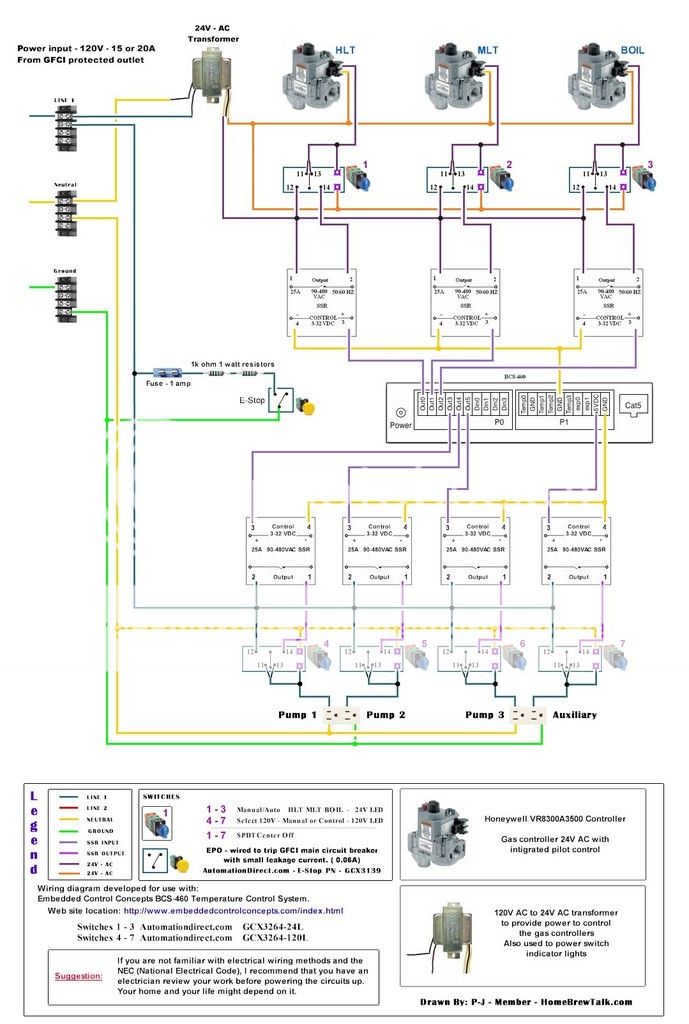

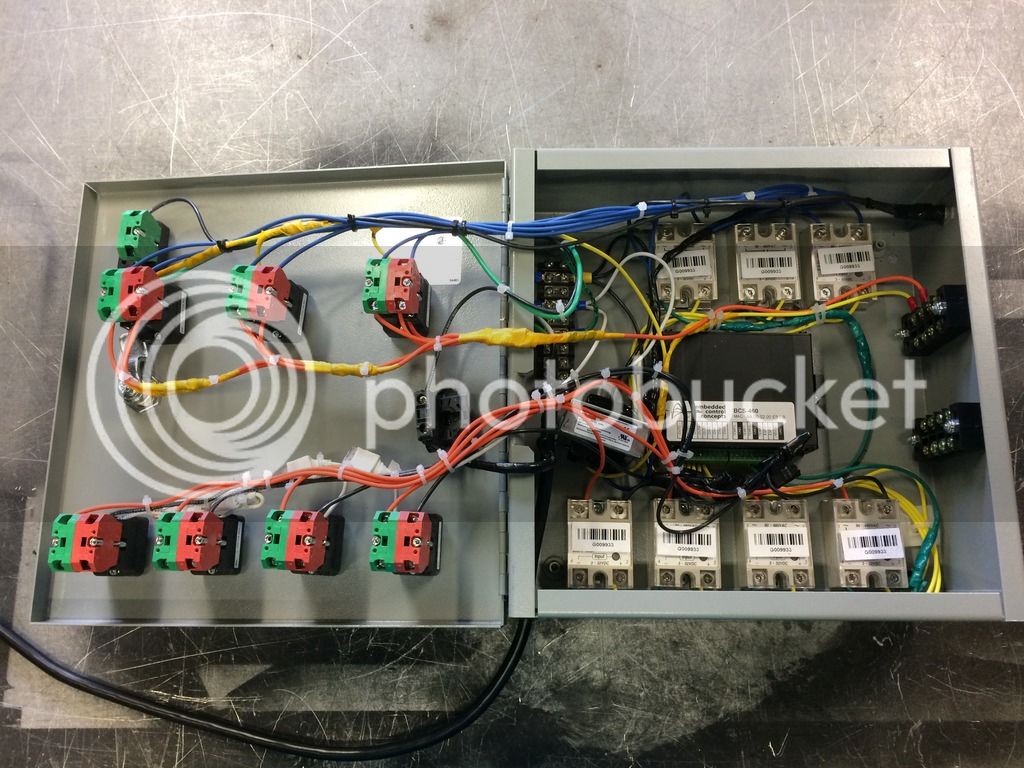

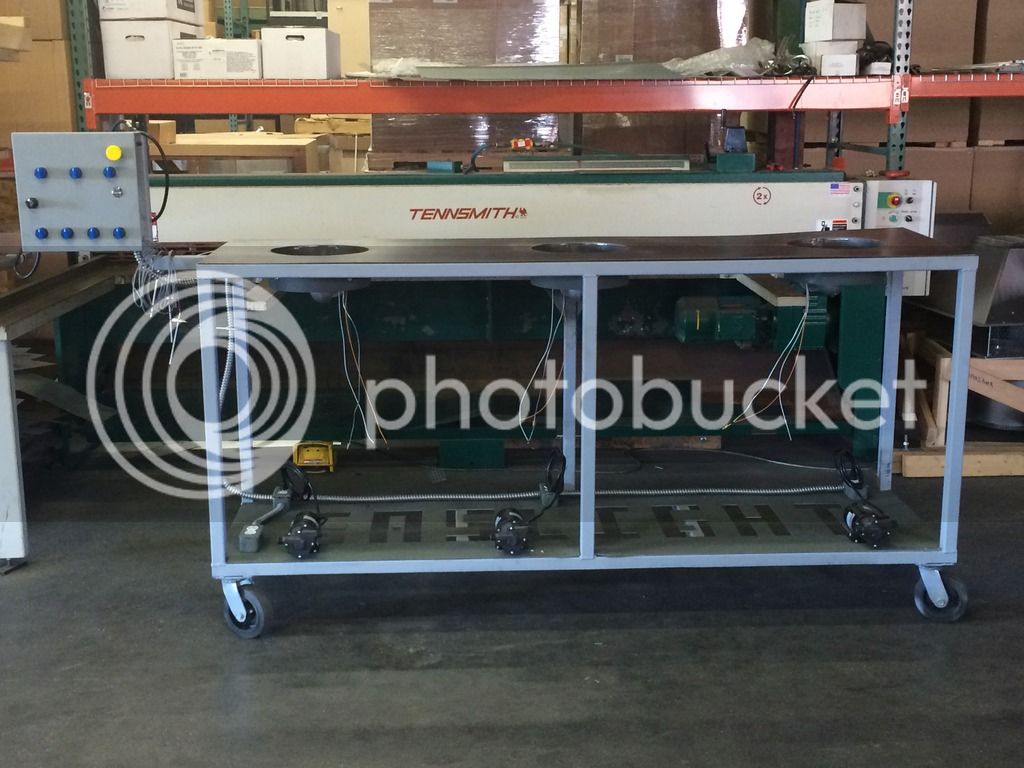

So, let's begin: The plan all along has been a single tier, propane-fueled direct-fired system (as much as I know about how the electric heating systems work and how safe they are, I just can't bring myself to pretty much stick electricity into water... I just can't do it.), 30 gallon kettles purchased from the guy's at Brewer's Hardware, 3 pumps, plate chiller, hop infuser, all run off a BCS-460 controlled panel to be at least partially automated.

Now, that's the plan... But anyone who knows me, knows that for better or worse, sometimes things don't go to plan. So, I hope I can either provide a little bit of inspiration for those looking at making their own brewstand, or at the very least give you all a chance to laugh at my pain!

I started out with the rolling frame for this bad boy, 1-1/2" square tube, roughly 1/8" thick, mild steel. My welding skills are nothing to write home about, but they should be good enough to hold this thing together even under a full load.

So, let's begin: The plan all along has been a single tier, propane-fueled direct-fired system (as much as I know about how the electric heating systems work and how safe they are, I just can't bring myself to pretty much stick electricity into water... I just can't do it.), 30 gallon kettles purchased from the guy's at Brewer's Hardware, 3 pumps, plate chiller, hop infuser, all run off a BCS-460 controlled panel to be at least partially automated.

Now, that's the plan... But anyone who knows me, knows that for better or worse, sometimes things don't go to plan. So, I hope I can either provide a little bit of inspiration for those looking at making their own brewstand, or at the very least give you all a chance to laugh at my pain!

I started out with the rolling frame for this bad boy, 1-1/2" square tube, roughly 1/8" thick, mild steel. My welding skills are nothing to write home about, but they should be good enough to hold this thing together even under a full load.