I've decided that my first dedicated AG rig would be a BIAB unit for the sake of simplicity. After weeks of browsing threads of note by ScubaSteve, Navy_Brewer, HossTheGreat, Seven and great contributions to my understanding of electronics by Kal and P-J (cheers ya'll  ) I've decided to take the plunge and begin the process of burning my house down.

) I've decided to take the plunge and begin the process of burning my house down.

I've assimilated a a few wiring diagrams and came up with this.

Please don't let me burn my house down, I think I understand the basics but I slept through circuits and wouldn't mind critiques on this thing. Also, a 30 AMP GFCI can power this element and a March pump right? I think it should, so I plan on adding a fused and switched outlet to the system to power my pump as well.

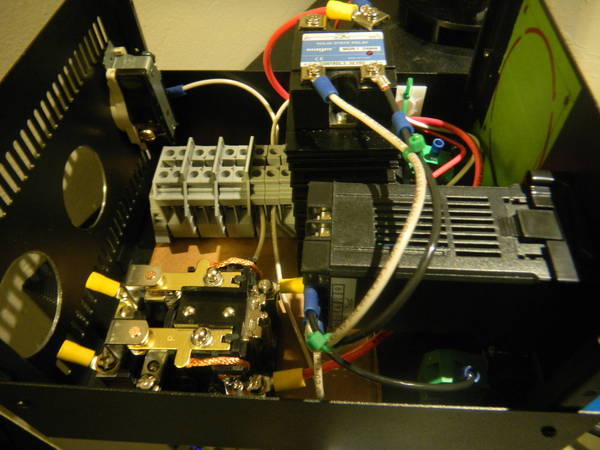

As a way of thanks I'm including some brewporn of my soon to be assembled BIAB rig. Enjoy!

) I've decided to take the plunge and begin the process of burning my house down.

) I've decided to take the plunge and begin the process of burning my house down.

I've assimilated a a few wiring diagrams and came up with this.

Please don't let me burn my house down, I think I understand the basics but I slept through circuits and wouldn't mind critiques on this thing. Also, a 30 AMP GFCI can power this element and a March pump right? I think it should, so I plan on adding a fused and switched outlet to the system to power my pump as well.

As a way of thanks I'm including some brewporn of my soon to be assembled BIAB rig. Enjoy!

Last edited by a moderator: