WolfieBrew

Well-Known Member

I am about to pull the trigger on my order for sanitary fittings. I was hoping to get some quick answers (or any feedback) to a few of my concerns based on my rough sketch.

I plan to use 1" ferrules for all connections except for the (4) thermometer ports and (1) future heating element port (HLT) which will be 1.5". My intention is the hard plumb all my lines down the road but, to start, i will use rubber hose to connect my pump. I plan to start with 1"/1.5" Tri Clover X 3/4" Hose Barb fittings from BrewersHardware.com.

Per their item description: typically used to make a Tri Clover to 3/4" tubing connection, many people stretch 1/2" tubing over this fitting so they can maintain a full 1/2" bore through their system. By simply heating Silicone tubing or clear PVC tubing in boiling water for a few minutes, it can be stretched over this fitting providing a larger flow path.

It sounds like the 1/2" ID for lines and fittings is tried and true and meshes perfectly with the 809 march pump and I figured using the 1/1.5" ferrules on the equipment would lend well to expansion as parts are more readily available... and less expensive the 1/2"/3/4".

QUESTIONS/CONCERNS BEFORE ORDERING/WELDING:

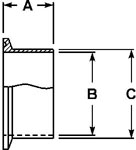

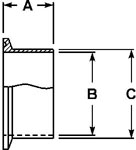

1. The butt weld ferrules are 1.125" long (Dim A in pic). Will this allow enough space to attached tri-clamps on inside and outside of keg wall? My welder said go with the least expensive ferrules and they can make it work.

2. On the brew magic system, the fittings are about 3" off the walls of the kegs, will heat create a problem with the fittings being closer? I personally would not think so and I am sure many people have went this route because it is much cheaper than the long 3" fittings.

3. Any recommendations on positioning the thermometer, sight tube fittings to ensure that they don't interfere with one another? I added (2) on the MLT b/c I can always cap one if I don't want to use. Now is the time to add what I need.

4. Any suggestions for adding additional ferrules while I am having the welding completed?

Any feedback would be great before i dive into this stage of my project.

Chris

I plan to use 1" ferrules for all connections except for the (4) thermometer ports and (1) future heating element port (HLT) which will be 1.5". My intention is the hard plumb all my lines down the road but, to start, i will use rubber hose to connect my pump. I plan to start with 1"/1.5" Tri Clover X 3/4" Hose Barb fittings from BrewersHardware.com.

Per their item description: typically used to make a Tri Clover to 3/4" tubing connection, many people stretch 1/2" tubing over this fitting so they can maintain a full 1/2" bore through their system. By simply heating Silicone tubing or clear PVC tubing in boiling water for a few minutes, it can be stretched over this fitting providing a larger flow path.

It sounds like the 1/2" ID for lines and fittings is tried and true and meshes perfectly with the 809 march pump and I figured using the 1/1.5" ferrules on the equipment would lend well to expansion as parts are more readily available... and less expensive the 1/2"/3/4".

QUESTIONS/CONCERNS BEFORE ORDERING/WELDING:

1. The butt weld ferrules are 1.125" long (Dim A in pic). Will this allow enough space to attached tri-clamps on inside and outside of keg wall? My welder said go with the least expensive ferrules and they can make it work.

2. On the brew magic system, the fittings are about 3" off the walls of the kegs, will heat create a problem with the fittings being closer? I personally would not think so and I am sure many people have went this route because it is much cheaper than the long 3" fittings.

3. Any recommendations on positioning the thermometer, sight tube fittings to ensure that they don't interfere with one another? I added (2) on the MLT b/c I can always cap one if I don't want to use. Now is the time to add what I need.

4. Any suggestions for adding additional ferrules while I am having the welding completed?

Any feedback would be great before i dive into this stage of my project.

Chris