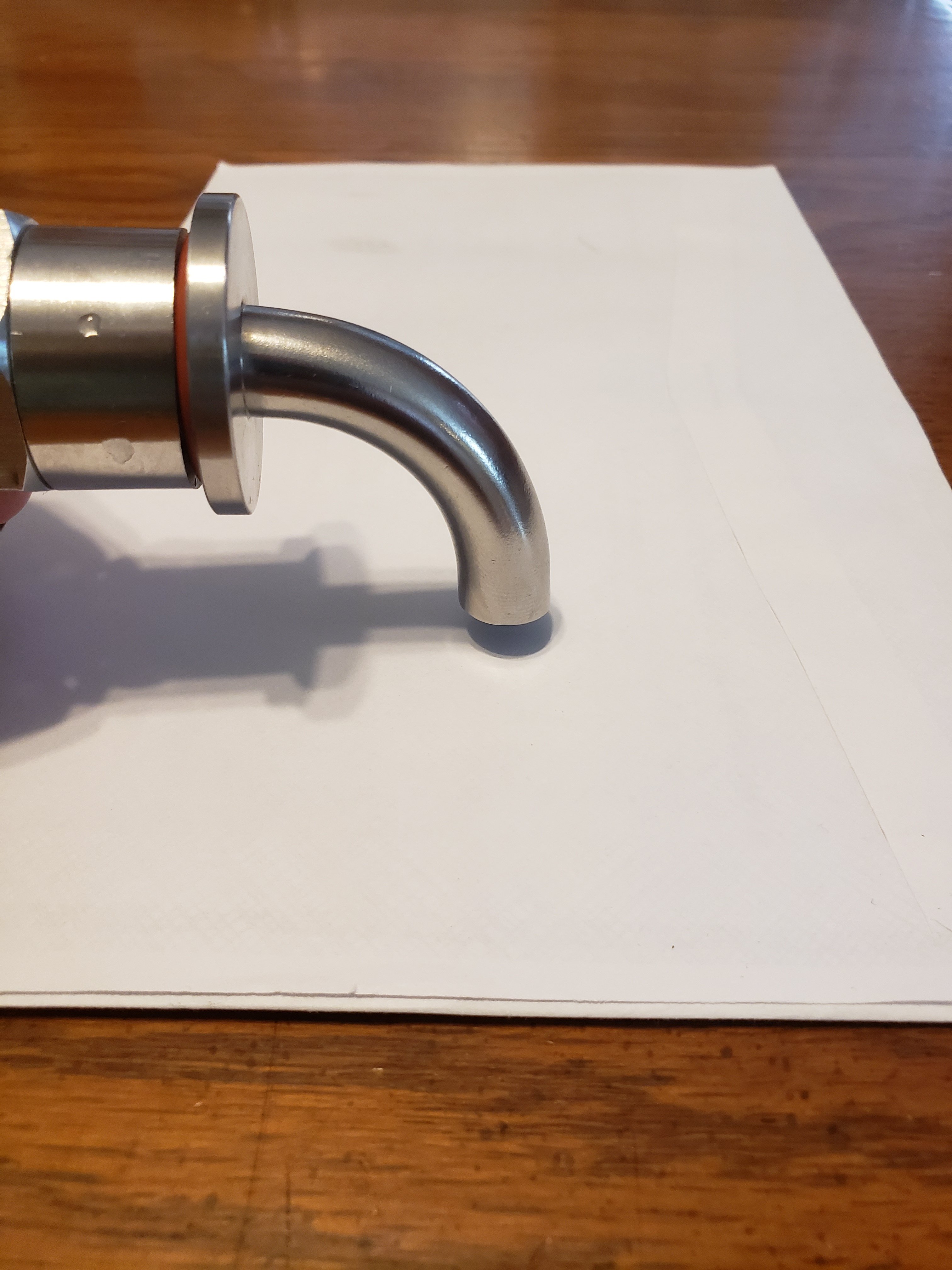

Been looking at various bulkhead fitting for adding two, maybe three, to a kettle having none presently.

These here ones without threads inside the kettle look pretty nifty. The interior connection being push-in with internal orings I suppose isn't as universal as 1/2" NPT, but there is a push-in to 1/2" NPT adapter and/or push-in to 1/2" hose barb adapter.

Anyone here using them, or other thoughts/opinions on them?

These here ones without threads inside the kettle look pretty nifty. The interior connection being push-in with internal orings I suppose isn't as universal as 1/2" NPT, but there is a push-in to 1/2" NPT adapter and/or push-in to 1/2" hose barb adapter.

Anyone here using them, or other thoughts/opinions on them?

Last edited: