Golddiggie

Well-Known Member

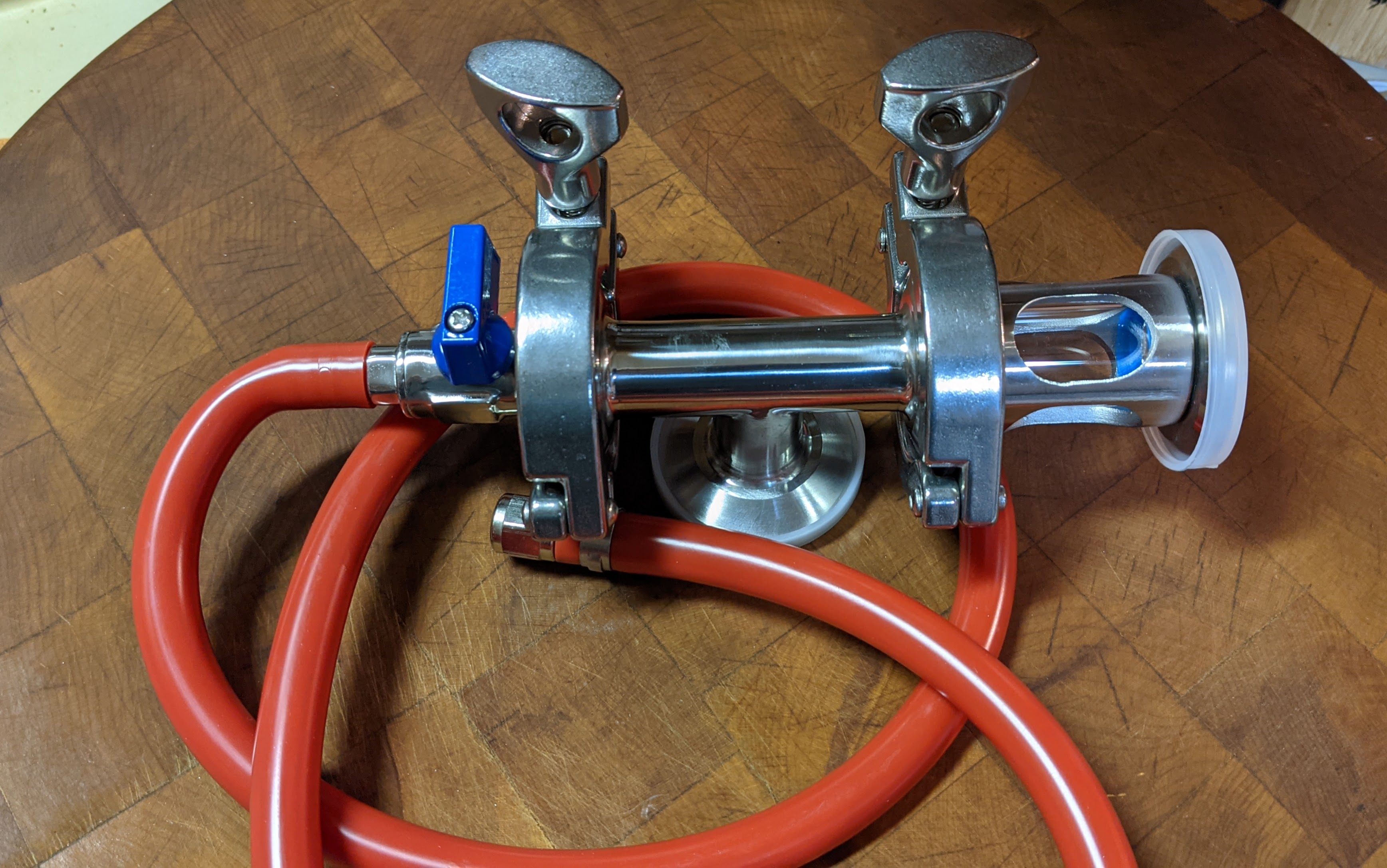

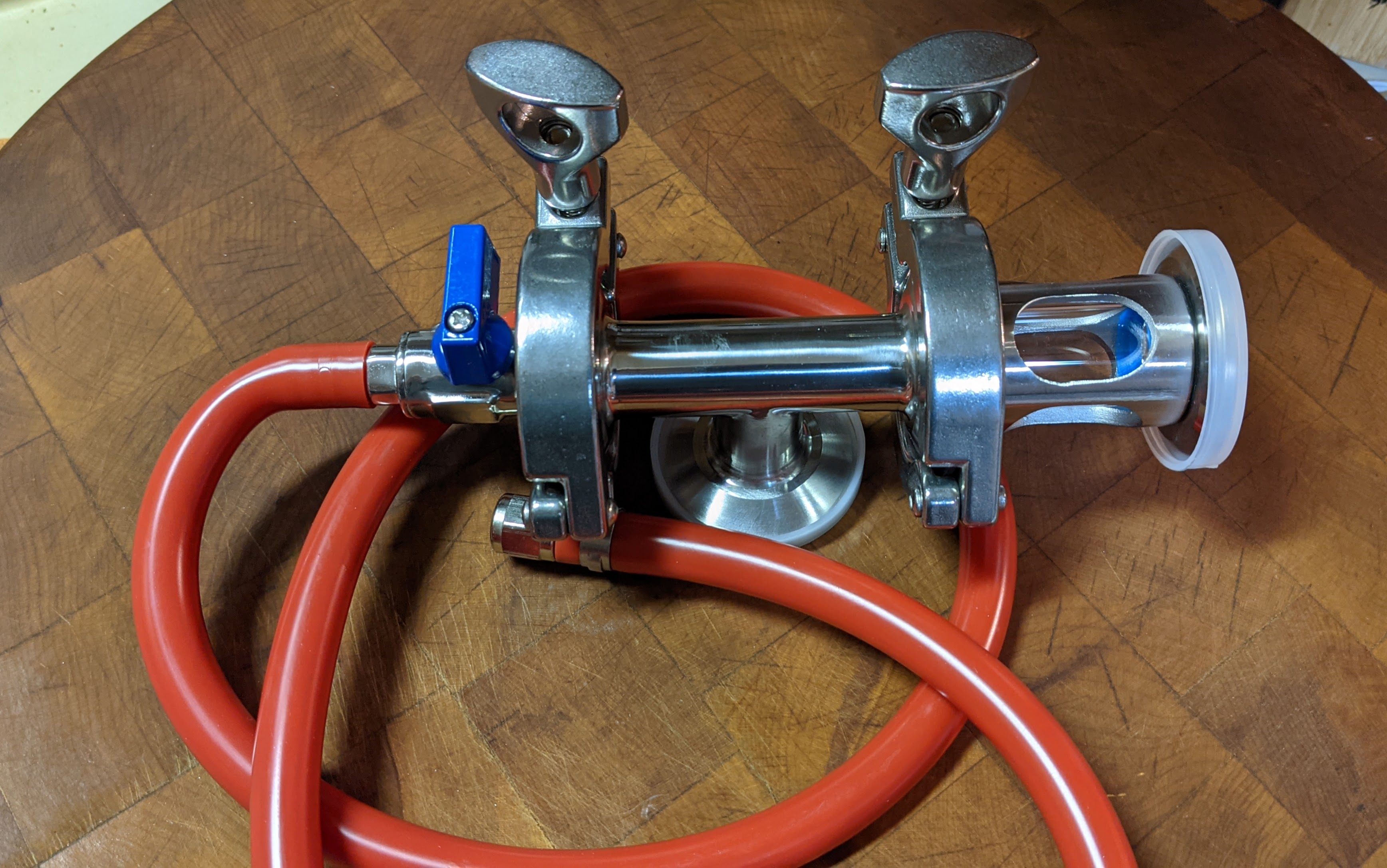

I've been using the same regulator (and O2 bottle) for ages. I like the regulator since it's easy to set to different L/min levels via the knob on the end. In the past I've been using it with an O2 wand (stainless wand, with the stone welded to it), also purchased ages ago (early 2011 IIRC).

Now, I plan to use the SSBrewTech O2 infusion item at the plate chiller (chilled wort out). I stopped off at AirGas on Friday on my way home from the LHBS in Trashua (NH). No dice on ANYTHING that would allow me to connect the tubing needed. No dice there. No fittings that will mate to the regulator with either a 3/8" or 5/15" barb. Or even 1/4" NPT fitting. Hell, even a 1/4" MFL would have worked. Since it was 'nope' across the board I figured "screw it, I'll MAKE something."

So here's the second one I made. First was longer than it needed to be by about 3/4". So I cut another piece of brass round stock and made the second one. It's 1-3/8" long. Made from 7/8" brass round bar. I machined the flats on it for use with a standard 3/4" wrench (because F metric).

I used an square ER40 collet holder to do all the machining. If I make another, I'll set up the rotary table with it's 3 jaw chuck to hold it while boring and tapping the holes. I did pick up the tap I needed for the regulator fitting, along with the correct size drill bit. I already had the 1/4" NPT tap and end mills the correct size for that hole.

I did a leak check on the brass adapter and it passed without issue. I did apply some Teflon tape as insurance.

I've already put a length of 5/16" gas tubing onto the SSBrewTech hardware. That was a piece that I already had a swivel nut on.

Now I'll be able to simply use a gas QD on either O2 infusion item I'm going to use for what I'm making and not need to deal with anything else.

Now, I plan to use the SSBrewTech O2 infusion item at the plate chiller (chilled wort out). I stopped off at AirGas on Friday on my way home from the LHBS in Trashua (NH). No dice on ANYTHING that would allow me to connect the tubing needed. No dice there. No fittings that will mate to the regulator with either a 3/8" or 5/15" barb. Or even 1/4" NPT fitting. Hell, even a 1/4" MFL would have worked. Since it was 'nope' across the board I figured "screw it, I'll MAKE something."

So here's the second one I made. First was longer than it needed to be by about 3/4". So I cut another piece of brass round stock and made the second one. It's 1-3/8" long. Made from 7/8" brass round bar. I machined the flats on it for use with a standard 3/4" wrench (because F metric).

I used an square ER40 collet holder to do all the machining. If I make another, I'll set up the rotary table with it's 3 jaw chuck to hold it while boring and tapping the holes. I did pick up the tap I needed for the regulator fitting, along with the correct size drill bit. I already had the 1/4" NPT tap and end mills the correct size for that hole.

I did a leak check on the brass adapter and it passed without issue. I did apply some Teflon tape as insurance.

I've already put a length of 5/16" gas tubing onto the SSBrewTech hardware. That was a piece that I already had a swivel nut on.

Now I'll be able to simply use a gas QD on either O2 infusion item I'm going to use for what I'm making and not need to deal with anything else.