That is a question for cuda6pak regarding the aquarium chiller. For heating, I was originally going to use my RIMS tube and the little stand I built for it. But, I decided that was probably going to result in air pockets getting into the RIMS tube and ultimately a burned out element. So, I decided to use a cooler, a bucket heater like this

http://www.amazon.com/dp/B000BDB4UG/?tag=skimlinks_replacement-20 a temp controller, a sump pump and a garden hose that screws right on to the outlet of my sump pump. The other end of the hose is cut off and a sanitary fitting with a hose barb is inserted and clamped onto the end of the hose. I like to use white potable hose for RVs available at RV stores and WalMart in the automotive/RV section. The nice thing about the sump pump is it is from my diy keg cleaner. So as Alton Brown likes to say, it is not a uni-tasker. There are several examples of that right here on HBT. Don't use the cooling valve assembly that comes with the BIAC for heating.

The temp controller will keep the water in the cooler at a specified temp by activating the bucket heater. The ETC that came with the BIAC (Ranco in my case) will monitor the temp in the 3-in-1. That will turn on the sump pump in the cooler when the temp in the 3-in-1 falls. The water inside the 3-in-1 jacket will just drain right back into the cooler when the ETC shuts off the pump. The RIMS tube method was definitely more compact, but I just don't think it would work w/o using a reservoir.

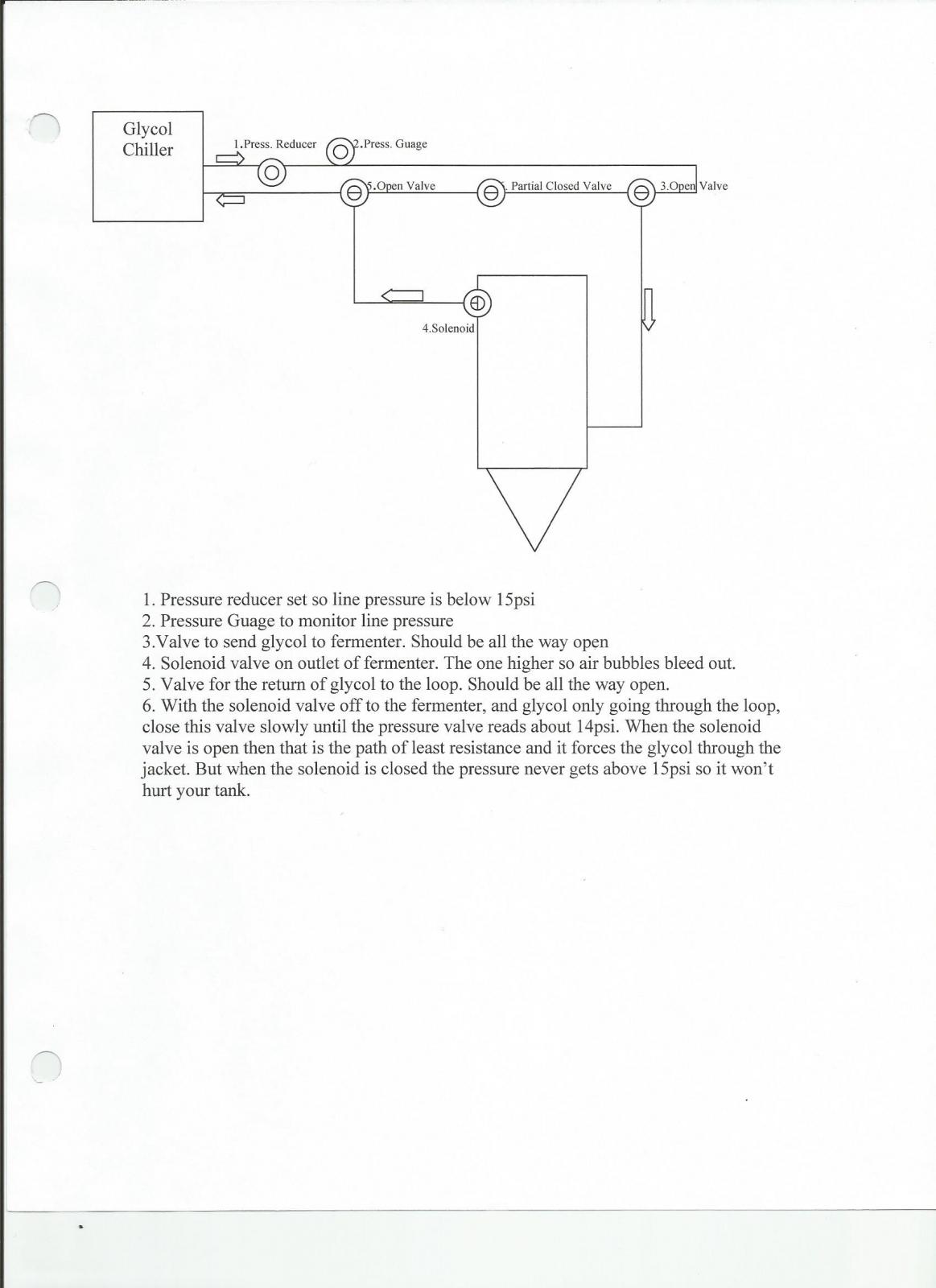

For cooling, I will be using a 1/3 HP glycol unit with a 2gal reservoir. But, I have not used that yet.

QUOTE=Cmason;6732545]I have been following this discussion since December, and after lots of looking have decided on a Medium BIAC. I am still working out the fermentation temp control. Will the reef chiller support cold crashing, or do I have to plan for a small glycol unit?

For those with a glycol unit, are you chilling a water resivor or running direct to the jacket?

I saw one comment on using the element to provide heat at 1% power setting, any updated feed back on how that is going?

Any one using a BrewPi or similar programable unit to control the fermentation temp profile?

I will be brewing in Williamsburg VA in the garage, so I will be dealing with temp fluctuations through the seasons and probably during the day in the summer.

I hope to order the BIAC by the end of May.

Thanks for everyone's time in responding.[/QUOTE]