rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

Ok. I know this topic has been covered, but I can't seem to find any people that are recently talking about doing this. I run a RIMS tube for my mash. My set up is a bottom drain insulated keg and I use on of the Chinese tan pumps for the re-circulation. I also use a BIAB bag in the MT to allow me a finer crush than normal and aid in getting zero particulates in my pump. Lastly, I do no-sparge.

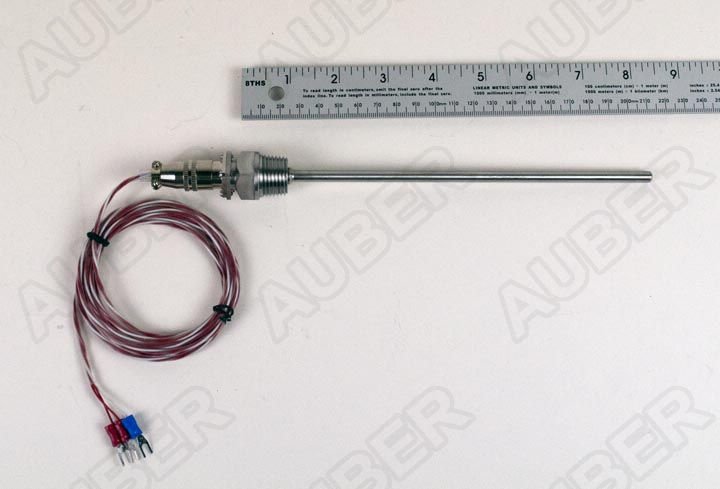

With that said, I've got close to 9 gallons or so of water along with the grain the MT when mashing. I'm currently running a 240V 4500W LWD element in the RIMS tube which gives me only 1150W in the tube. It's perfectly fine for maintaining temps, but when mashing out, it's loooooong. I mean 30 minutes to get to mash out temps long. Considering 9 gallons of water to heat, I can say I don't understand.

I want to see about putting a 2000W HW element in the RIMS tube and see the results. I understand that the high density elements are no desirable for the BK due to scorching. Also, in a RIMS tube you risk scorching as well if the flow is too slow and the element contacts the same area of wort for too long. My thoughts are that because the pump is pumping wort at a decent rate, that it won't have any time at all to scorch.

Before we get to a possible stuck mash, let me say. I've got the BIAB and a false bottom sitting at the bottom of the MT. I doughed in and kicked the pump on last time and is flowed just perfectly throughout the whole mash. No throttling or anything.

So, can anyone with experience with this type of setup comment to it's ability to function and not scorch the wort?

With that said, I've got close to 9 gallons or so of water along with the grain the MT when mashing. I'm currently running a 240V 4500W LWD element in the RIMS tube which gives me only 1150W in the tube. It's perfectly fine for maintaining temps, but when mashing out, it's loooooong. I mean 30 minutes to get to mash out temps long. Considering 9 gallons of water to heat, I can say I don't understand.

I want to see about putting a 2000W HW element in the RIMS tube and see the results. I understand that the high density elements are no desirable for the BK due to scorching. Also, in a RIMS tube you risk scorching as well if the flow is too slow and the element contacts the same area of wort for too long. My thoughts are that because the pump is pumping wort at a decent rate, that it won't have any time at all to scorch.

Before we get to a possible stuck mash, let me say. I've got the BIAB and a false bottom sitting at the bottom of the MT. I doughed in and kicked the pump on last time and is flowed just perfectly throughout the whole mash. No throttling or anything.

So, can anyone with experience with this type of setup comment to it's ability to function and not scorch the wort?