I've always been a BIAB brewer since I started brewing in 2010. I was initially attracted to the simplicity--everything I needed to brew in one kettle, which at the time was a paper-thin aluminum 7.5 gallon kettle that came with a turkey frying stand.

Fast forward five years and like most people in this hobby, I've steadily upgraded my gear to the point where it's hard to call my BIAB setup simple: 18.5 gallon stainless kettle with welded ports for thermometer and valve, bazooka tube, chugger pump, plate chiller and of course my Wilserbrewer BIAB bags. And camlocks. Camlocks are great.

This setup has netted me some good and sometimes fantastic beer. It generally works great--with one exception that is common to BIAB: mash temperature control.

I used to start at a higher temperature and let it fall over the course of the mash so that it averaged out at my target mash temperature but I was never satisfied with the lack of precision. I tried direct heating from my propane burner stand but I tended to overshoot the temperature. I tried recirculating while direct heating and I managed to burn a Wilserbrewer bag--the pump sucked it down to the bottom of the kettle and it melted.

I was committed to BIAB but I was frustrated and really wanted total control over all elements of my brew process. I read many amazing eBIAB build threads here for systems featuring internal RIMS setups but they were typically 240v and if they were 120v they were for smaller batch sizes. I brew 10 gallon batches and I need portability--I brew both on my deck and in the garage depending on the weather. More importantly, I often brew with a friend at his home. I can't rely on access to 240v. I also wanted the flexibility of using other kettles in the future and didn't want to commit my current kettle by adding a port for a heating element.

I spent a lot of time researching this forum and other online resources, specifically looking for examples that would prove the viability of an external 120v RIMS tube with 10 gallon batches. Not to reach my strike temperature or to boil, but just to dial in my mash temperature. I was still worried about thermal loss via the kettle and whether a 120v RIMS tube could keep up--but it seemed plausible so I bit the bullet and purchased an 18" RIMS tube and 5500w 240v element (which I run on 120v at 1375w for very low watt density) from brewhardware.com as well as a tabletop plug and play controller (built around a SYL-2352) with a 4" probe from auberins.com.

I had time to assemble it all yesterday and brewed with it today. My friend came over and we brewed an amber ale in my kettle plus a Pliny clone in his--both 10 gallon batches. I'm very happy to report that the external 120v RIMS worked perfectly. We were able to precisely hold our mash temperatures and I liked that we could use it (one after the other) on both kettles given that it's external. I also installed a wireless remote that controls power to my pump--very convenient.

I wanted to share my thinking and report my success here for others simply because I couldn't find examples of my exact situation when I was researching it. I hope this helps someone else down the road.

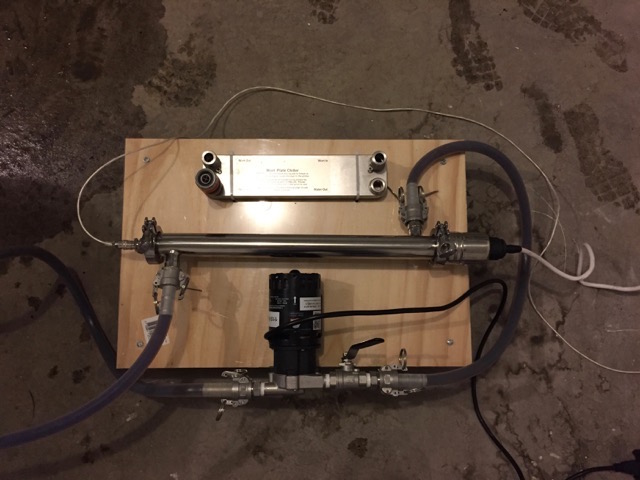

Next step is the building of portable platform where I can mount my pump, RIMS tube and chiller with expansion room for a future hopback acquisition. I'll add some photos when I wrap that up.

Fast forward five years and like most people in this hobby, I've steadily upgraded my gear to the point where it's hard to call my BIAB setup simple: 18.5 gallon stainless kettle with welded ports for thermometer and valve, bazooka tube, chugger pump, plate chiller and of course my Wilserbrewer BIAB bags. And camlocks. Camlocks are great.

This setup has netted me some good and sometimes fantastic beer. It generally works great--with one exception that is common to BIAB: mash temperature control.

I used to start at a higher temperature and let it fall over the course of the mash so that it averaged out at my target mash temperature but I was never satisfied with the lack of precision. I tried direct heating from my propane burner stand but I tended to overshoot the temperature. I tried recirculating while direct heating and I managed to burn a Wilserbrewer bag--the pump sucked it down to the bottom of the kettle and it melted.

I was committed to BIAB but I was frustrated and really wanted total control over all elements of my brew process. I read many amazing eBIAB build threads here for systems featuring internal RIMS setups but they were typically 240v and if they were 120v they were for smaller batch sizes. I brew 10 gallon batches and I need portability--I brew both on my deck and in the garage depending on the weather. More importantly, I often brew with a friend at his home. I can't rely on access to 240v. I also wanted the flexibility of using other kettles in the future and didn't want to commit my current kettle by adding a port for a heating element.

I spent a lot of time researching this forum and other online resources, specifically looking for examples that would prove the viability of an external 120v RIMS tube with 10 gallon batches. Not to reach my strike temperature or to boil, but just to dial in my mash temperature. I was still worried about thermal loss via the kettle and whether a 120v RIMS tube could keep up--but it seemed plausible so I bit the bullet and purchased an 18" RIMS tube and 5500w 240v element (which I run on 120v at 1375w for very low watt density) from brewhardware.com as well as a tabletop plug and play controller (built around a SYL-2352) with a 4" probe from auberins.com.

I had time to assemble it all yesterday and brewed with it today. My friend came over and we brewed an amber ale in my kettle plus a Pliny clone in his--both 10 gallon batches. I'm very happy to report that the external 120v RIMS worked perfectly. We were able to precisely hold our mash temperatures and I liked that we could use it (one after the other) on both kettles given that it's external. I also installed a wireless remote that controls power to my pump--very convenient.

I wanted to share my thinking and report my success here for others simply because I couldn't find examples of my exact situation when I was researching it. I hope this helps someone else down the road.

Next step is the building of portable platform where I can mount my pump, RIMS tube and chiller with expansion room for a future hopback acquisition. I'll add some photos when I wrap that up.