Your wife can't smell?

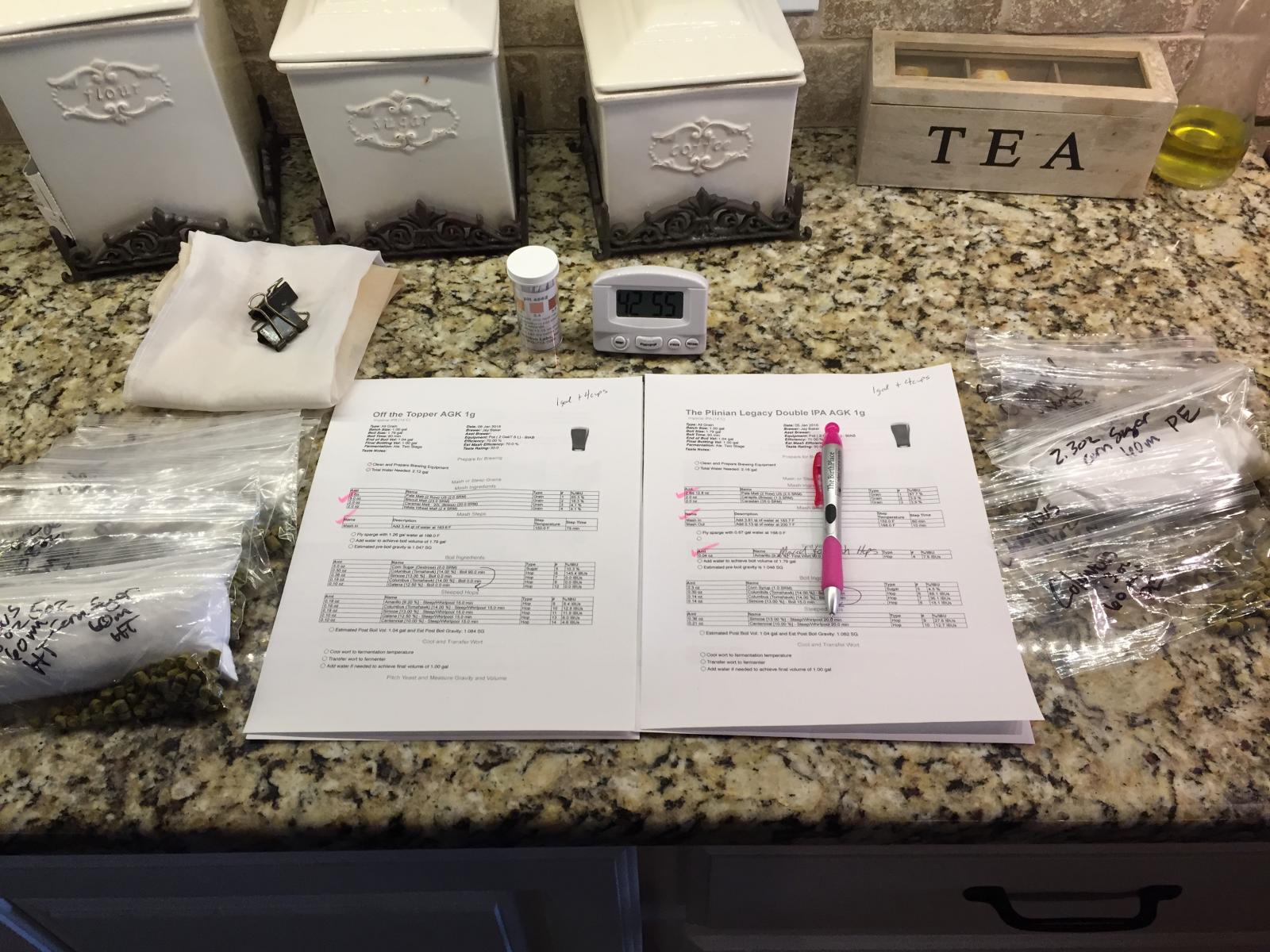

I would have screwed up doing all the different schedules. The heady clone I did actually came with hop oil syringes!

Do you have a copy of the pliney clone?

Nope she can't smell, I can fart in the car on a hot summer day and she can't smell it.

Recipe: The Plinian Legacy Double IPA AGK 1g

Asst Brewer:

Style: Imperial IPA

TYPE: All Grain

Recipe Specifications

--------------------------

Boil Size: 1.79 gal

Post Boil Volume: 1.04 gal

Batch Size (fermenter): 1.00 gal

Bottling Volume: 1.00 gal

Estimated OG: 1.080 SG

Estimated Color: 7.4 SRM

Estimated IBU: 195.6 IBUs

Boil Time: 90 Minutes

Ingredients:

------------

Amt Name

2 lbs 13 oz Pale Malt (2 Row) US

2.0 oz Carapils (Briess) (1.5 SRM)

2.0 oz Carastan (35.0 SRM)

0.04 oz Amarillo [9.20 %] - Mash Hop

0.30 oz Columbus (Tomahawk) [14.00 %] - Boil 90.

0.14 oz Columbus (Tomahawk) [14.00 %] - Boil 45.

0.14 oz Simcoe [13.00 %] - Boil 15.0 min

2.3 oz Corn Syrup (1.0 SRM) Flame Out

0.36 oz Simcoe [13.00 %] - Steep/Whirlpool 20min

0.21 oz Centennial [10.00 %] - Steep/Whirlpool 20min

0.29 oz Columbus (Tomahawk) [14.00 %] - Dry Hop

0.19 oz Centennial [10.00 %] - Dry Hop 14.0 Days

0.19 oz Simcoe [13.00 %] - Dry Hop 14.0 Days

0.10 oz Columbus (Tomahawk) [14.00 %] - Dry Hop

0.10 oz Simcoe [13.00 %] - Dry Hop 7.0 Days

0.05 oz Amarillo [9.20 %] - Dry Hop 7.0 Days

0.05 oz Centennial [10.00 %] - Dry Hop 7.0 Days

I took the NB Pliney Clone scaled it with BeerSmith and subbed the Hop Shot with Columbus to match IBU.