Infidel

Well-Known Member

- Joined

- May 13, 2008

- Messages

- 88

- Reaction score

- 8

Just a post of caution, not that this is likely to happen to the average homebrewer...

Last year I had a wood shed built which holds my brewing and woodworking equipment.

The last week of December I needed to remove what was either a zinc or galvanized coating from 4 small brackets so they could be welded and painted. Used a quart of muratic acid (30% hydrochloric acid) in a plastic shoebox.

To prevent animals from getting close to the toxic mix I put the mix in the shed and closed the door. I waited 18 hours for the acid to strip the coating off and it worked great! Very clean steel. Rinsed, washed and it was ready to work - nice clean steel.

Oh, the disaster part?

Two weeks later I went to get something out of the shed and noticed small evenly spaced black dots on my brewery. It appeared to be an oil. I was in a hurry and figured it was stainless and would simply wash off. I couldn't guess what it was.

Two more weeks go by and I wipe across one of the kettles to see what it is and notice some rust. Damn... this is bad, really bad.

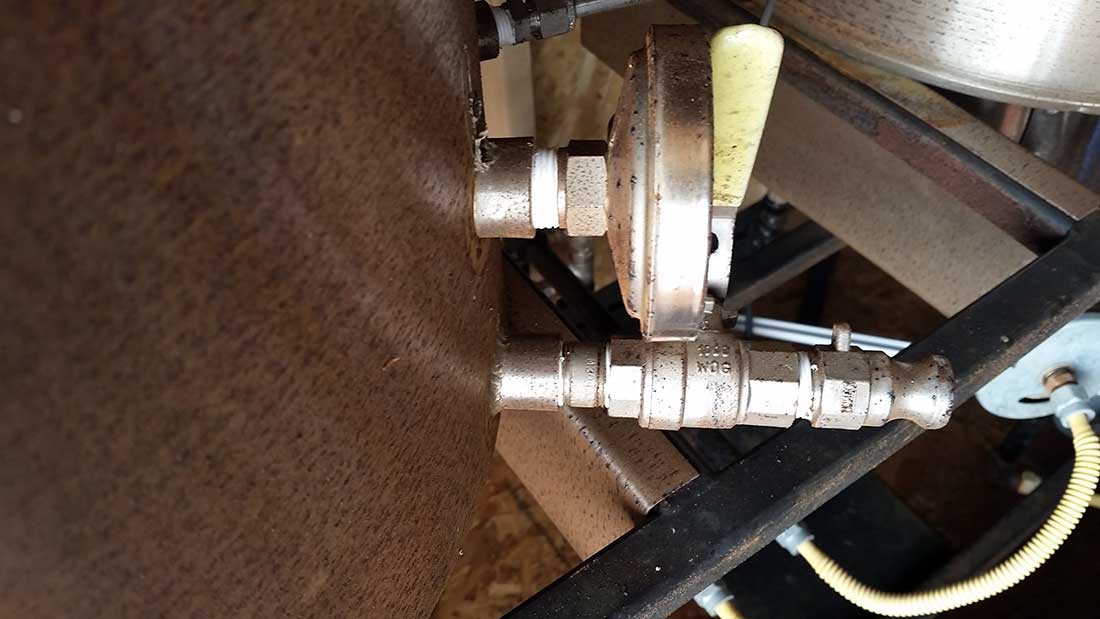

Note electrical connection corrosion above.

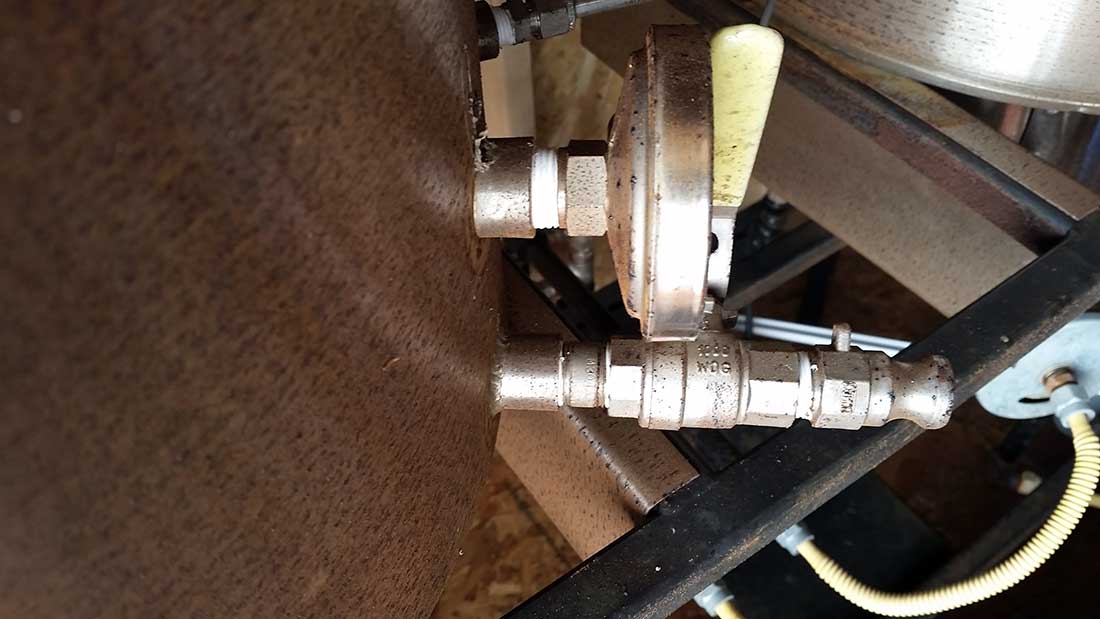

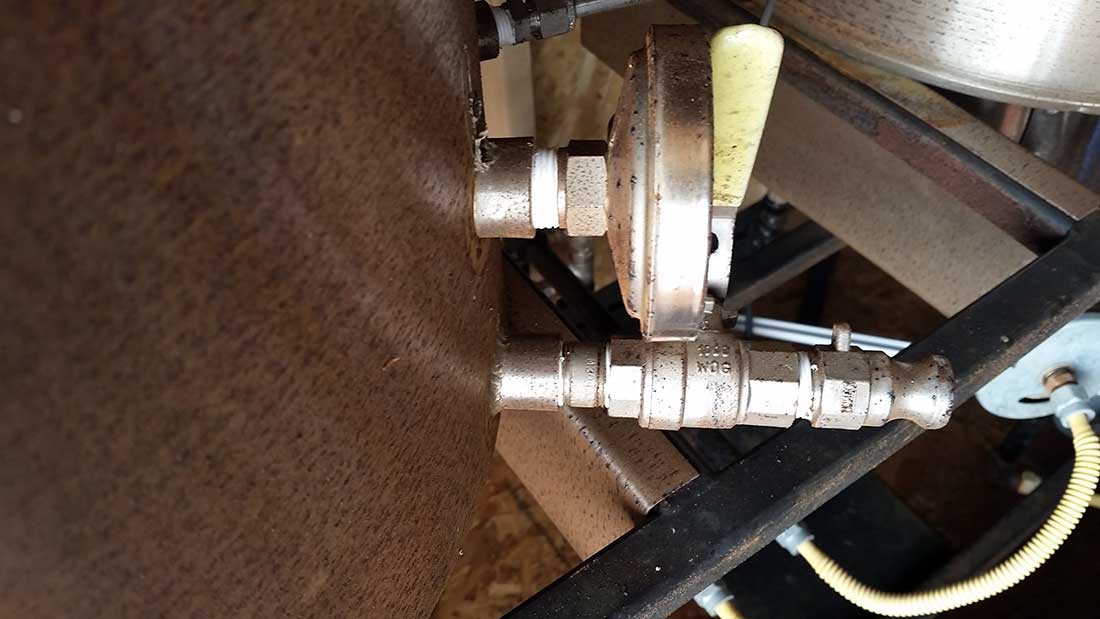

Below -that thermometer isn't a cheap import...

This piece was made from certified 316L originally destined for a semiconductor factory which was scrapped because it wasn't shipped to clean room spec's from what I was told. I bought the lot for less than a dime on the dollar. Maybe you bought a racking cane from a homebrew store in Austin a decade ago? Nice stuff, electropolished interior. Overkill, but this demonstrates how nasty the fumes were.

This is a stick of 1/2" aluminum bar stock. Note "growth" on surface.

Tools, not showing them. The table surfaces aren't exactly smooth. Blades rusted. I don't want to look at the routers or wonder about the motor interiors.

This is about 1/2 of the stainless removed for cleaning.

Scrubbing with various grades of scotchbrite pads and bar-keeper's friend after thoroughly washing with soap, baking soda.

I was only able to do half a kettle before giving up.

It cleaned up fair. I would say 70%. The corrosion is by no means "gone"... and I haven't even touched the interiors. I may see if a pro-brewer can get a passivating solution, but this isn't going to be just a simple chemical bath to clean up.

This isn't the kind of investment I can just write off and not sure I want to call the insurance company and try to explain my "off label" use of pool chemicals.

Of course all of the nails in the shed are rusted. Not sure how I will treat them. Wire brush then either oil or rust-olium? Spray interior ceiling with rubberized coating?

Copper stuff has some damage but I don't think it will be ruined.

The only thing that doesn't "appear" to be damaged are enamel and powder coated surfaces. I haven't thought to check the carboys. The few damn things I have with the finish I hate so much - galvanized... appears to be fine.

Suggestions?

Last year I had a wood shed built which holds my brewing and woodworking equipment.

The last week of December I needed to remove what was either a zinc or galvanized coating from 4 small brackets so they could be welded and painted. Used a quart of muratic acid (30% hydrochloric acid) in a plastic shoebox.

To prevent animals from getting close to the toxic mix I put the mix in the shed and closed the door. I waited 18 hours for the acid to strip the coating off and it worked great! Very clean steel. Rinsed, washed and it was ready to work - nice clean steel.

Oh, the disaster part?

Two weeks later I went to get something out of the shed and noticed small evenly spaced black dots on my brewery. It appeared to be an oil. I was in a hurry and figured it was stainless and would simply wash off. I couldn't guess what it was.

Two more weeks go by and I wipe across one of the kettles to see what it is and notice some rust. Damn... this is bad, really bad.

Note electrical connection corrosion above.

Below -that thermometer isn't a cheap import...

This piece was made from certified 316L originally destined for a semiconductor factory which was scrapped because it wasn't shipped to clean room spec's from what I was told. I bought the lot for less than a dime on the dollar. Maybe you bought a racking cane from a homebrew store in Austin a decade ago? Nice stuff, electropolished interior. Overkill, but this demonstrates how nasty the fumes were.

This is a stick of 1/2" aluminum bar stock. Note "growth" on surface.

Tools, not showing them. The table surfaces aren't exactly smooth. Blades rusted. I don't want to look at the routers or wonder about the motor interiors.

This is about 1/2 of the stainless removed for cleaning.

Scrubbing with various grades of scotchbrite pads and bar-keeper's friend after thoroughly washing with soap, baking soda.

I was only able to do half a kettle before giving up.

It cleaned up fair. I would say 70%. The corrosion is by no means "gone"... and I haven't even touched the interiors. I may see if a pro-brewer can get a passivating solution, but this isn't going to be just a simple chemical bath to clean up.

This isn't the kind of investment I can just write off and not sure I want to call the insurance company and try to explain my "off label" use of pool chemicals.

Of course all of the nails in the shed are rusted. Not sure how I will treat them. Wire brush then either oil or rust-olium? Spray interior ceiling with rubberized coating?

Copper stuff has some damage but I don't think it will be ruined.

The only thing that doesn't "appear" to be damaged are enamel and powder coated surfaces. I haven't thought to check the carboys. The few damn things I have with the finish I hate so much - galvanized... appears to be fine.

Suggestions?