So excited to get brewing on the new system! Last night, I did a number of different tests and simulations, ran auto tune on the PID controller and I am ready to go! First brew day is on Friday.

I put together the design based on my intended process as well as trying to best utilize components I already owned. It's kind of a "2.5 vessel" single tier system. The vessel on the far right in the pictures below is simply a reservoir for holding heated sparge water. There is only 1 heating element (240v, 4500w BoilCoil), in the 15 gallon Blichmann in the middle, and that vessel serves as both the HERMS tank as well as the boil kettle.

The mash tun is in the 11 gallon cooler on the left, into which I put a calibrated thermometer and a Blichmann AutoSparge. The mash is recirculated by one of the two center inlet Chugger pumps through the 50ft 1/2" diameter SS HERMS coil mounted in the Blichmann, then back through the AutoSparge set with the valve wide open. At the same time, the HERMS water is recirculated through the other Chugger pump to the recirc port on the top right. When the mash is done, the sparge water is heated then pumped over to the cooler on the right through the HERMS coil to clean it. Then the HERMS coils is removed via the tri-clover fittings, and sparging can occur as it would in a normal 3-vessel system.

There is another recirculation port on the lower right of the Blichmann just below my typical post-boil volume for whirlpooling.

Chilling is through the Stainless Steel convoluted counter-flow down at the bottom left. I put a T fitting on the wort out port so I could monitor wort temp.

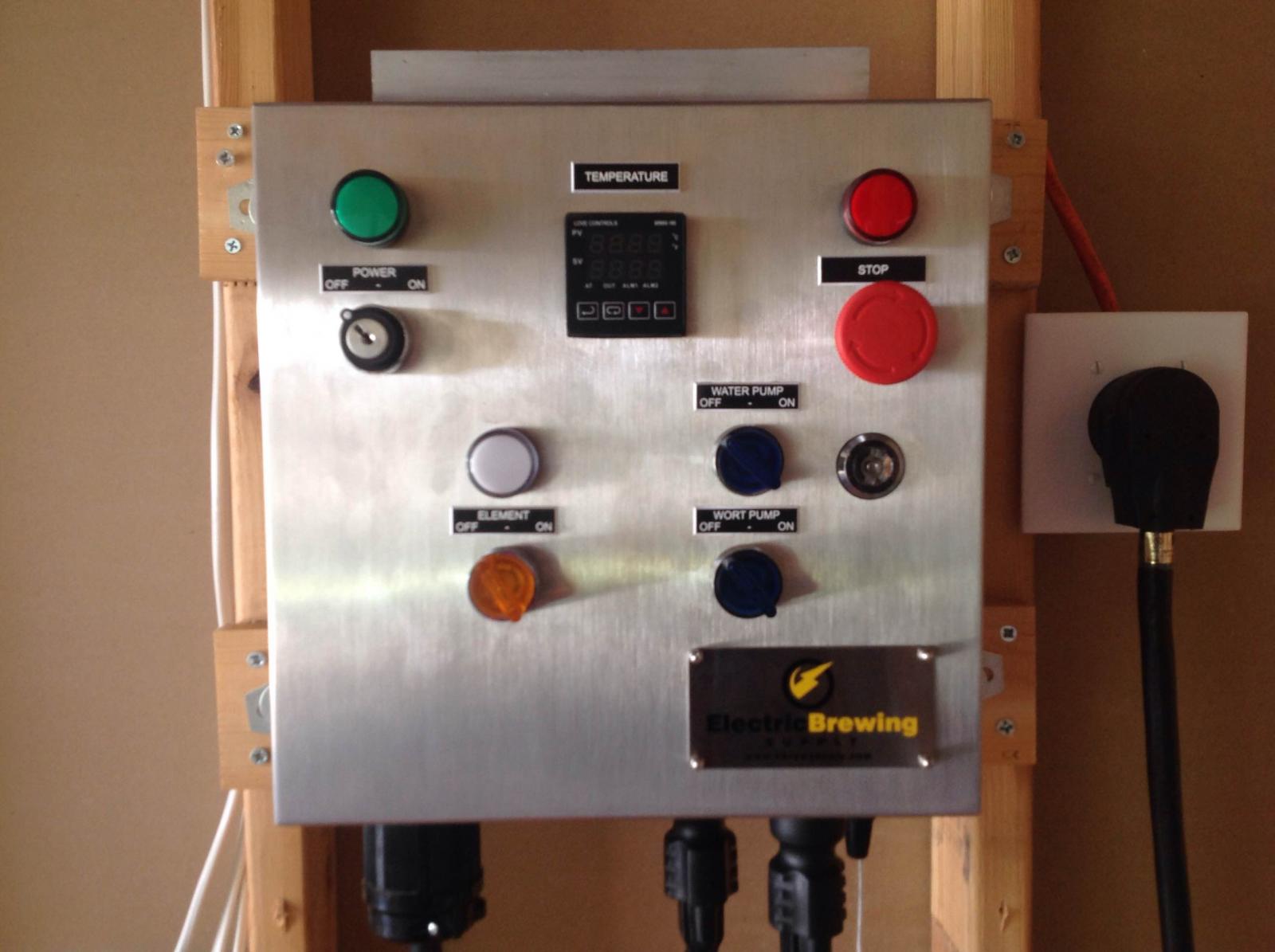

The control panel is a slightly modified version of the single element design from Electric Brewing Supply. Basically, I just added the switch and outlet for the second pump.

Pics!

I put together the design based on my intended process as well as trying to best utilize components I already owned. It's kind of a "2.5 vessel" single tier system. The vessel on the far right in the pictures below is simply a reservoir for holding heated sparge water. There is only 1 heating element (240v, 4500w BoilCoil), in the 15 gallon Blichmann in the middle, and that vessel serves as both the HERMS tank as well as the boil kettle.

The mash tun is in the 11 gallon cooler on the left, into which I put a calibrated thermometer and a Blichmann AutoSparge. The mash is recirculated by one of the two center inlet Chugger pumps through the 50ft 1/2" diameter SS HERMS coil mounted in the Blichmann, then back through the AutoSparge set with the valve wide open. At the same time, the HERMS water is recirculated through the other Chugger pump to the recirc port on the top right. When the mash is done, the sparge water is heated then pumped over to the cooler on the right through the HERMS coil to clean it. Then the HERMS coils is removed via the tri-clover fittings, and sparging can occur as it would in a normal 3-vessel system.

There is another recirculation port on the lower right of the Blichmann just below my typical post-boil volume for whirlpooling.

Chilling is through the Stainless Steel convoluted counter-flow down at the bottom left. I put a T fitting on the wort out port so I could monitor wort temp.

The control panel is a slightly modified version of the single element design from Electric Brewing Supply. Basically, I just added the switch and outlet for the second pump.

Pics!