Hello everyone!

I've started home brewing a couple weeks ago and came up with a small project to cold down liquids in general (BEER!)

I decided to use Peltier for several reasons, I do know there are other systems.

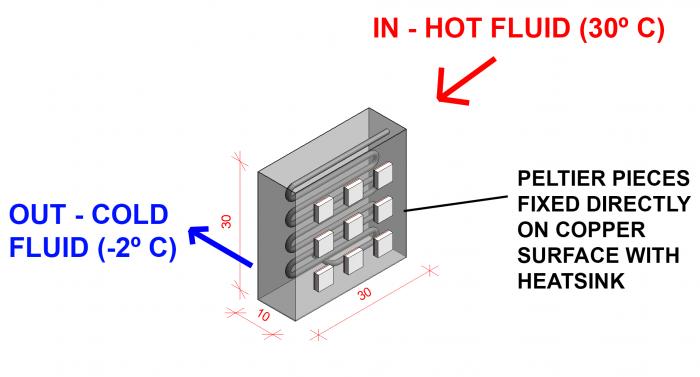

So, here's the idea... I'll have a copper container of 30x30x10 cm, holding about 900 ml of water. Inside of the container it will have a copper tube as some sort of serpentine to make liquid get trhough. So the water inside the container has the purpose to get cold enough so the liquid inside the serpentine can get cold as well. Is it clear as I explained?

My initial idea is that in the back of the copper container I'll place a few Peltier pieces spreaded along, making the surface cold, so the water inside gets cold too and consequently the liquid inside the serpentine.

As of the pieces.. I've searched and came up with this:

9x Peltier 12V 60W 5.8A TEC1-12706

Temperature Controler STC-1000

Power Supply 12V 50A 600W Switch Power Supply Adapter

I really need help on this part, I'm far from decent in electronics.. So, you guys think thats all the electronics I'll need? Suggestions to improve the stuff?

Thanks a lot for the help!

I've started home brewing a couple weeks ago and came up with a small project to cold down liquids in general (BEER!)

I decided to use Peltier for several reasons, I do know there are other systems.

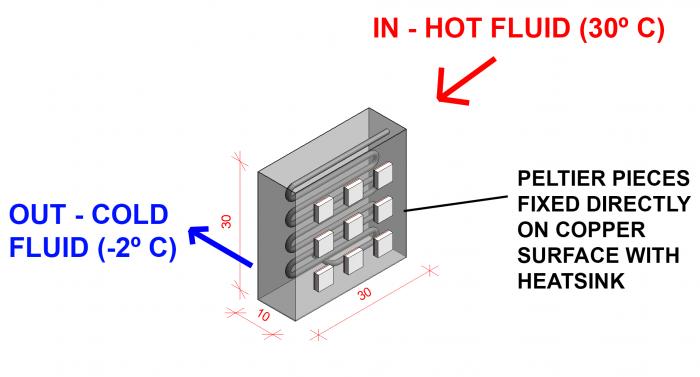

So, here's the idea... I'll have a copper container of 30x30x10 cm, holding about 900 ml of water. Inside of the container it will have a copper tube as some sort of serpentine to make liquid get trhough. So the water inside the container has the purpose to get cold enough so the liquid inside the serpentine can get cold as well. Is it clear as I explained?

My initial idea is that in the back of the copper container I'll place a few Peltier pieces spreaded along, making the surface cold, so the water inside gets cold too and consequently the liquid inside the serpentine.

As of the pieces.. I've searched and came up with this:

9x Peltier 12V 60W 5.8A TEC1-12706

Temperature Controler STC-1000

Power Supply 12V 50A 600W Switch Power Supply Adapter

I really need help on this part, I'm far from decent in electronics.. So, you guys think thats all the electronics I'll need? Suggestions to improve the stuff?

Thanks a lot for the help!