Good Morning gmtech,

Looks like that switch will work.

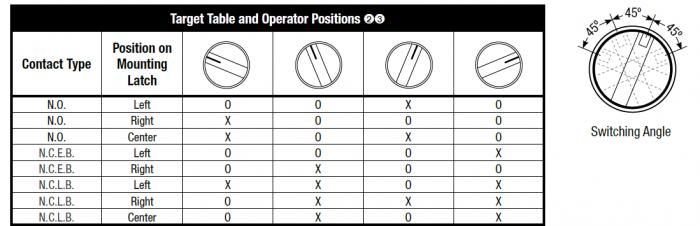

The OMEGA person is correct according to the chart.

You need two N.C.E.B. contacts and possibly a spare contact for spacing.

When they describe "Position on mounting latch", I don't know if they mean from viewed from the rear or not. Should be. It is important where the N.C.E.B. contacts are located on the switch though. Should be easy enough to unlatch and move them.

My first attempt would be:

Left - Stacked set of N. O. & N.C.E.B.

Center - Empty or the spare contact if needed

Right - N.C.E.B.

(Those Engineers sure put a lot of time into designing the cams/dogs inside them switch guts):cross:

You'll want to verify this with an OHM meter while the switch is 'in hand' and access is easy.

I was thinking of an alternative method last night and maybe you could use a more common 3-way switch for Sparge, Boil & Mash; with a "Heaters On" switch feeding that one.

The heaters on switch could be illuminated to tell who "Hey BrewMaster, the heaters are on"

Have a great one,

'da Kid