So, my buddy and I start a conversation about a possible DIY immersion chiller, and little as we know about thermal dynamics, it turned into a lot of "I wonder if..." questions.

Our 14.5g brewpot is custom made (by someone I bought it from used off of ebay a year ago). It's kind of large, circumference wise, and the little itty bitty 3/8" immersion chillers I see in the store don't look like they could handle our pot very well (small tubing, and smallish concentric rings), and they definately don't look like they could handle a full on 10g batch. We are thinking about doing a DIY, but had some questions for some people a lot smarter than us.

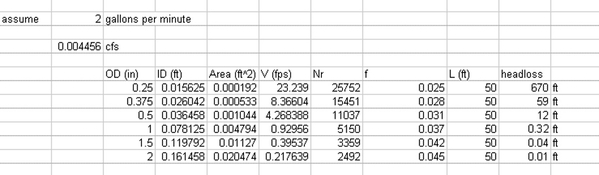

1. Our plan was to use 1/2 copper pipe. Does that really work better than the standard 3/8" stuff?

2. Our plan was to have 2 sets of rings, one larger ring to go closer to the sides of the brewpot, and another ring (of possibly smaller copper, maybe not) that resides INSIDE the larger outer ring. Does that sounds like it will cool wort faster than a single 50' of 3/8" pipe?

3. If we ran that water clockwise through the outer ring, and counter clockwise through the inner ring, would it make a difference?

4. If we ran water in the other direction (top to bottom, bottom to top) between the rings, would it make a difference?

Discuss...

Our 14.5g brewpot is custom made (by someone I bought it from used off of ebay a year ago). It's kind of large, circumference wise, and the little itty bitty 3/8" immersion chillers I see in the store don't look like they could handle our pot very well (small tubing, and smallish concentric rings), and they definately don't look like they could handle a full on 10g batch. We are thinking about doing a DIY, but had some questions for some people a lot smarter than us.

1. Our plan was to use 1/2 copper pipe. Does that really work better than the standard 3/8" stuff?

2. Our plan was to have 2 sets of rings, one larger ring to go closer to the sides of the brewpot, and another ring (of possibly smaller copper, maybe not) that resides INSIDE the larger outer ring. Does that sounds like it will cool wort faster than a single 50' of 3/8" pipe?

3. If we ran that water clockwise through the outer ring, and counter clockwise through the inner ring, would it make a difference?

4. If we ran water in the other direction (top to bottom, bottom to top) between the rings, would it make a difference?

Discuss...

I have a spare immersion wort chiller I need to get around to putting in a bucket with lots of ice and salt water in to pre chill my water. THEN it'll drop the time more, and in the winter when the water drops 10 or so degrees it'll help more too.

I have a spare immersion wort chiller I need to get around to putting in a bucket with lots of ice and salt water in to pre chill my water. THEN it'll drop the time more, and in the winter when the water drops 10 or so degrees it'll help more too.