CoopDvr

Active Member

I recently purchased a 1/2"x50' coil of 316 SS tubing for a new EHERMS system that I'm building. After reading of many failed attempts to coil by hand, I decided to build a proper roller.

First of all, I have to give a big thanks to V-twin for his roller build. My design is a bit different, but his build was the inspiration for my build. You can see his build here: https://www.homebrewtalk.com/f51/50-foot-1-2-inch-ss-coil-300138/index12.html

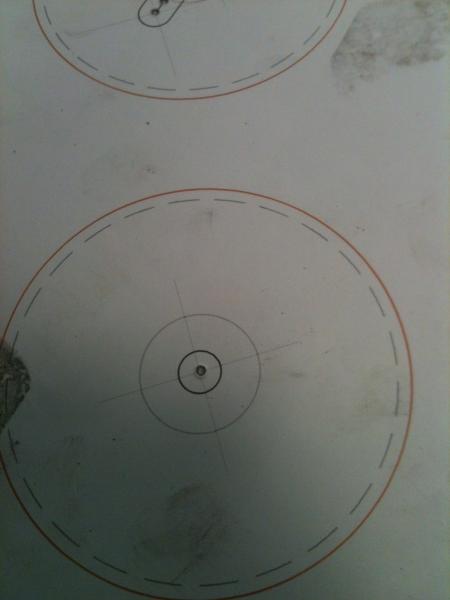

I bought three 1/2"x3" wire rope sheaves from Grainger. These have the bearings, so they roll with ease: http://www.grainger.com/Grainger/Sheave-5RTE0?Pid=search

The rest of the build is with scrap aluminum and fittings from my shop at work.

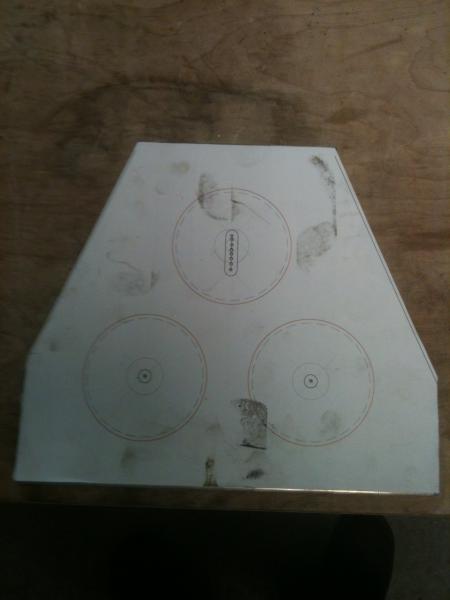

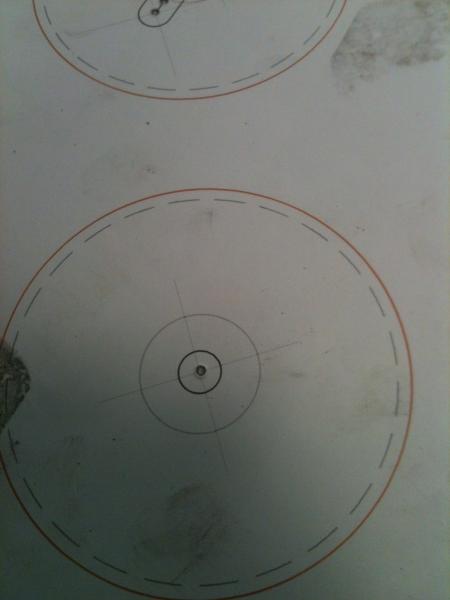

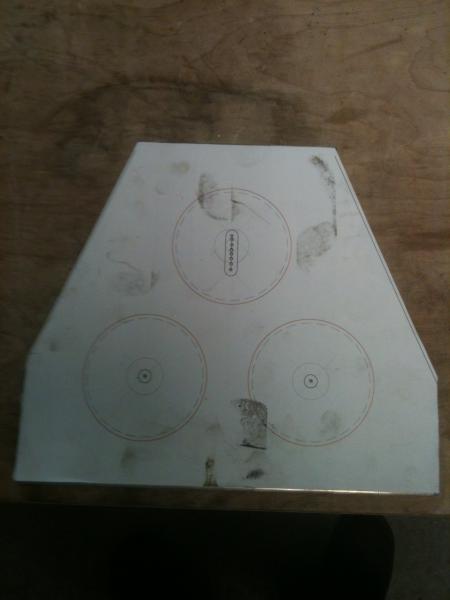

I used 1/8" pieces of aluminum sheet. I took two small pieces and attached them together with double sided tape. I then made a template and taped it to the panels. I cut and drilled the panels together through the template.

First of all, I have to give a big thanks to V-twin for his roller build. My design is a bit different, but his build was the inspiration for my build. You can see his build here: https://www.homebrewtalk.com/f51/50-foot-1-2-inch-ss-coil-300138/index12.html

I bought three 1/2"x3" wire rope sheaves from Grainger. These have the bearings, so they roll with ease: http://www.grainger.com/Grainger/Sheave-5RTE0?Pid=search

The rest of the build is with scrap aluminum and fittings from my shop at work.

I used 1/8" pieces of aluminum sheet. I took two small pieces and attached them together with double sided tape. I then made a template and taped it to the panels. I cut and drilled the panels together through the template.