blackheart

Well-Known Member

Some of you may have seen our current brew system. If not here is the thread.

https://www.homebrewtalk.com/f11/automated-herms-system-132119/

We have hit a few snags with the system after brewing several batches on it. This is not a design flaw in the overall system but rather inadequate valves. The 12v solonid valves we are currently using do not totally seal, closed or open, leaving us with partially closed valves which messes with the pressure needed to get liquids from A -> B

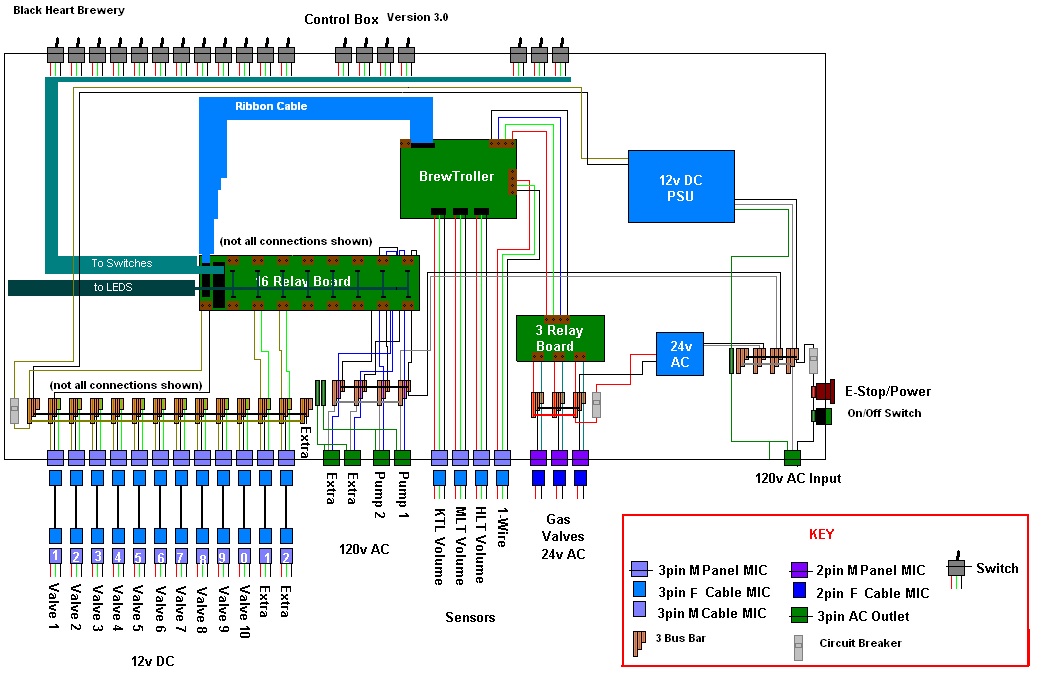

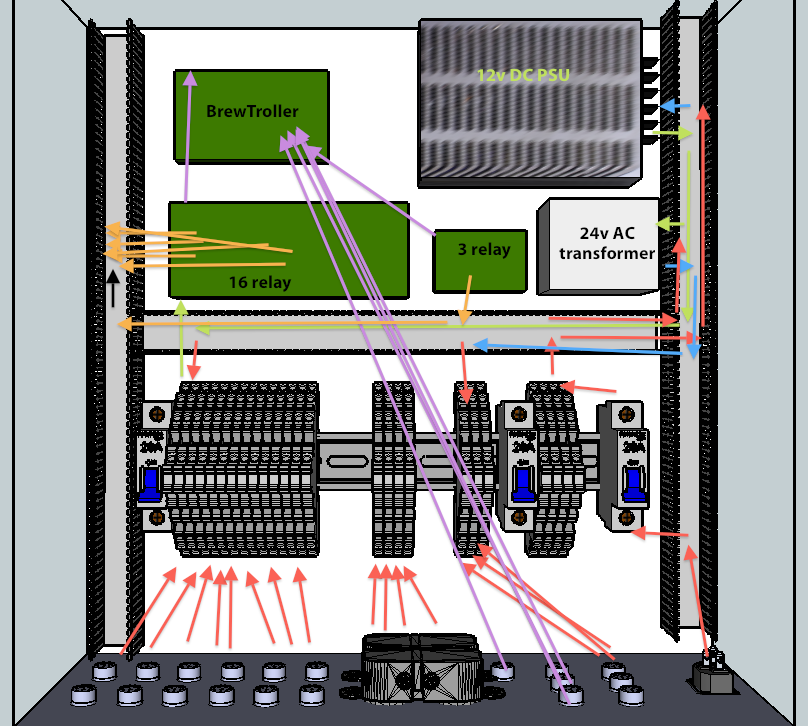

Also, we have been experimenting with building our own automated controller. While this has been fun, in the same time we have been building the brew system, Brew Troller has created more mature and reliable product. The relay board alone is worth using thanks to the addition of built in LED and manual/auto switches.

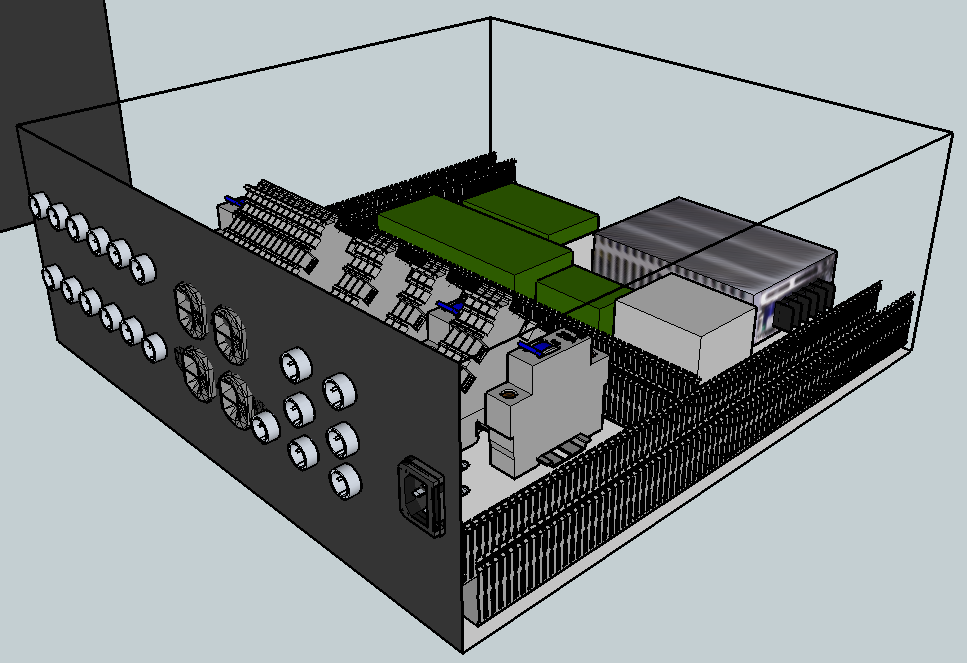

So we decided its time to rebuild, better, more automated, more modular.

Our current system is fairly modular using TC fittings and silicon tubing. This means we have almost all the parts we need to reconfigure everything with a wrench and some teflon tape. Their were a few other minor things that were bothering us.

- No dedicated water input

- No dedicated output to a fermentor

- Lots of wires hanging from the top down towards the burners

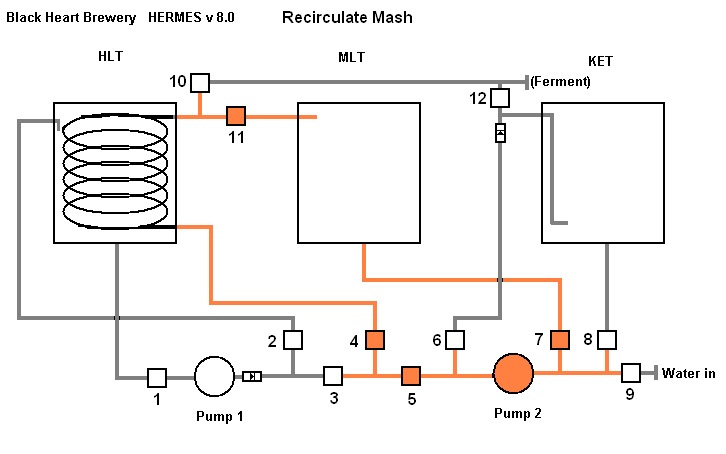

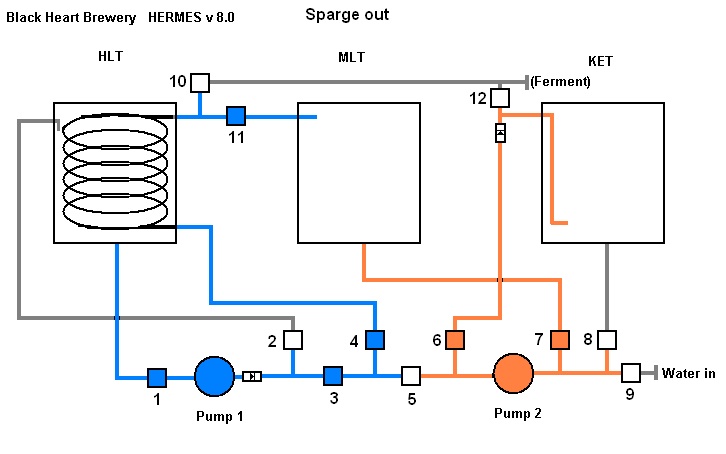

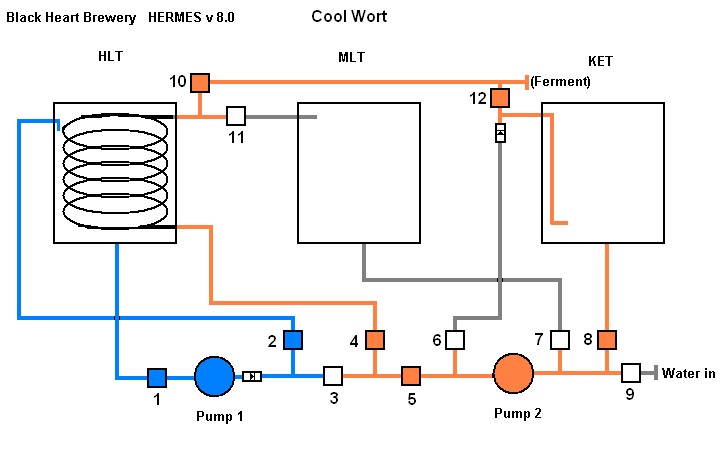

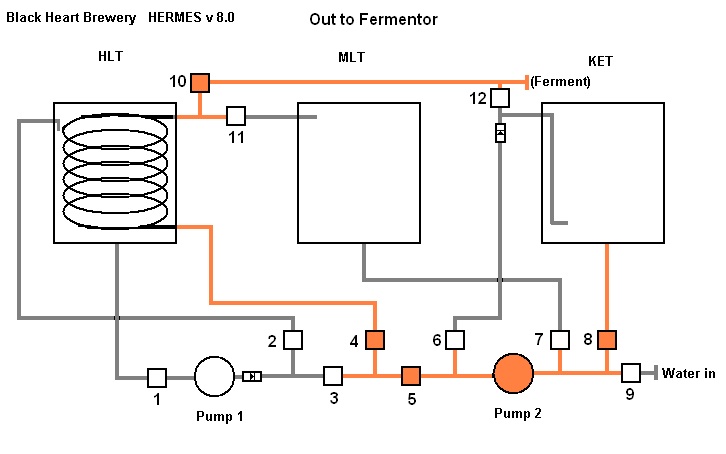

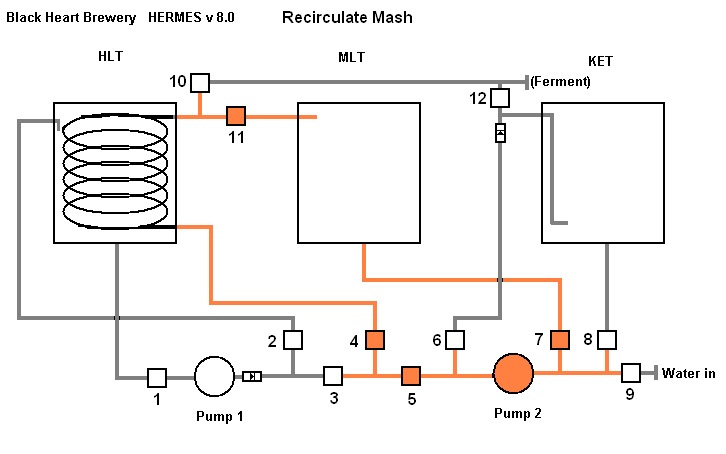

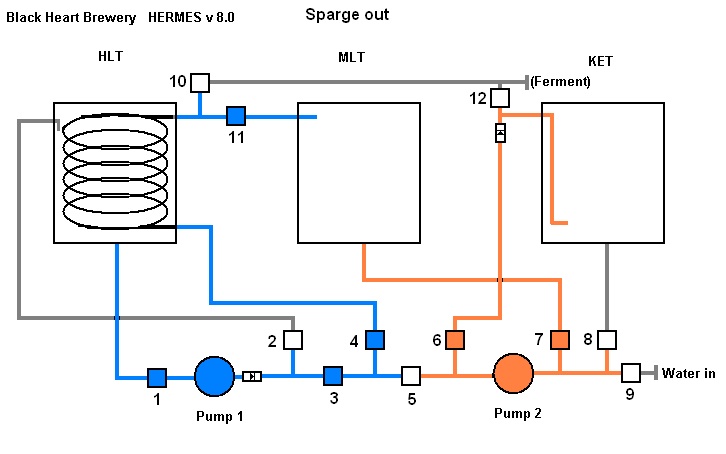

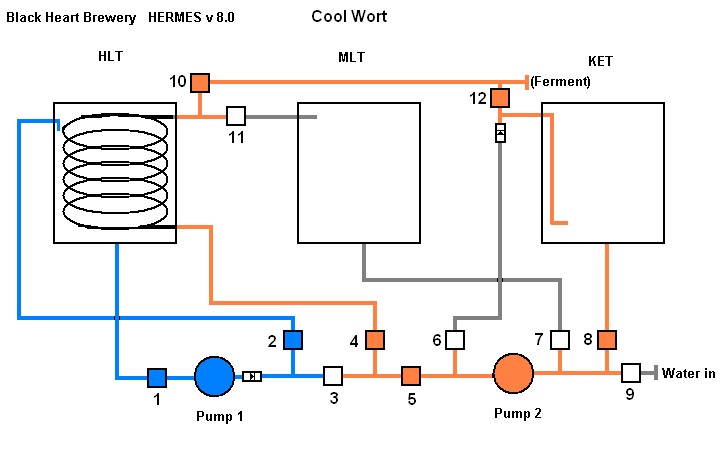

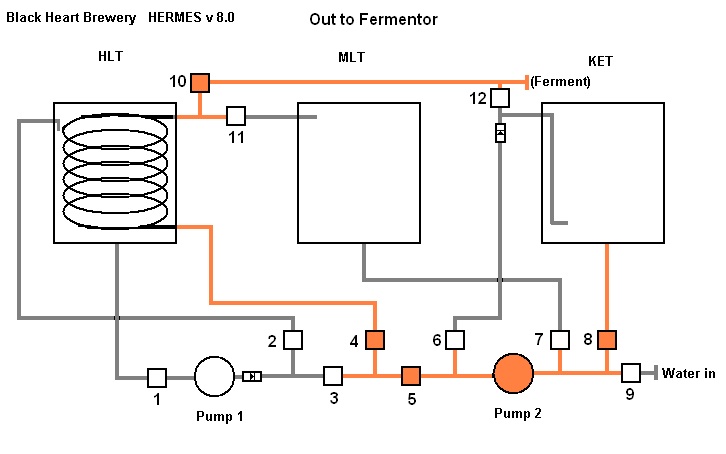

The original goal of our brew system was to make a HERMS system that used the coil for both recirculation and cooling. We havent figured out a permanent water connection to the garage/brewery for the winter so we cant rely on a plate chiller etc to cool the beer year round. This has proven difficult to design as many inputs and outputs overlap.

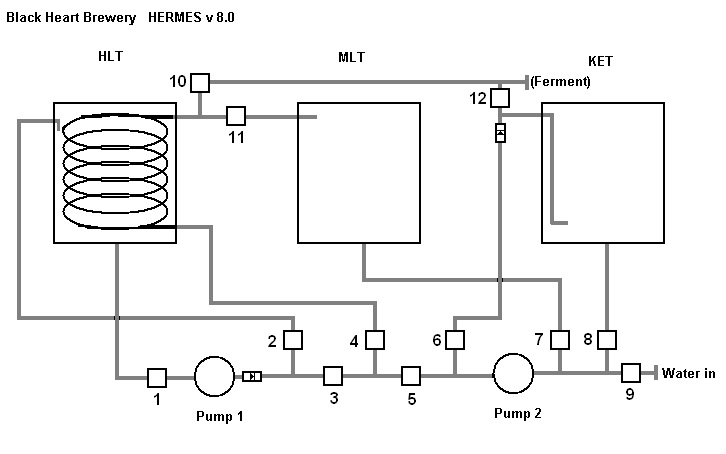

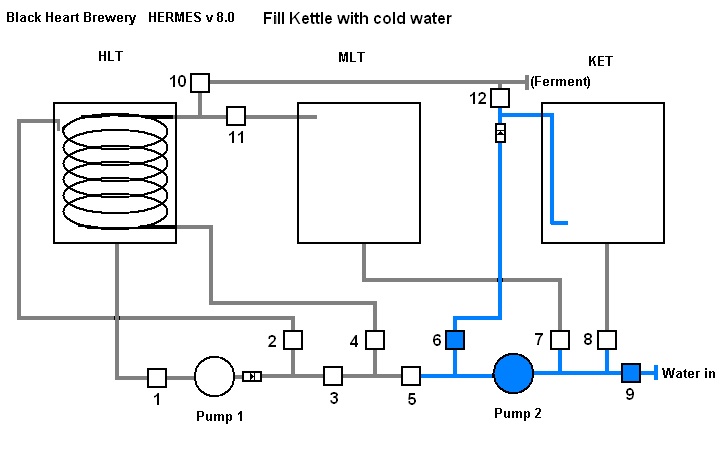

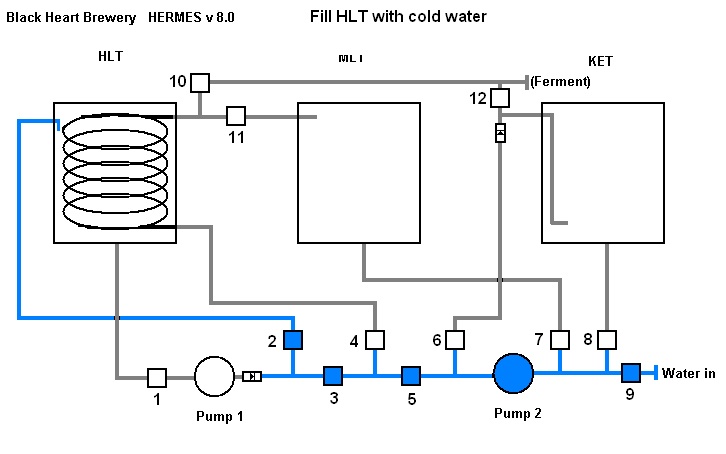

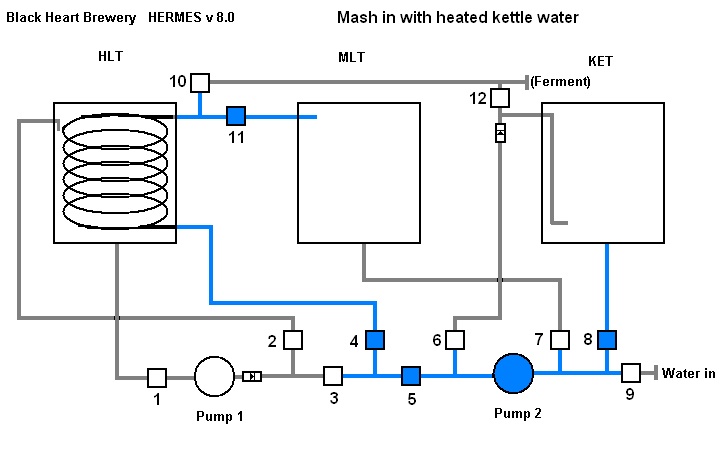

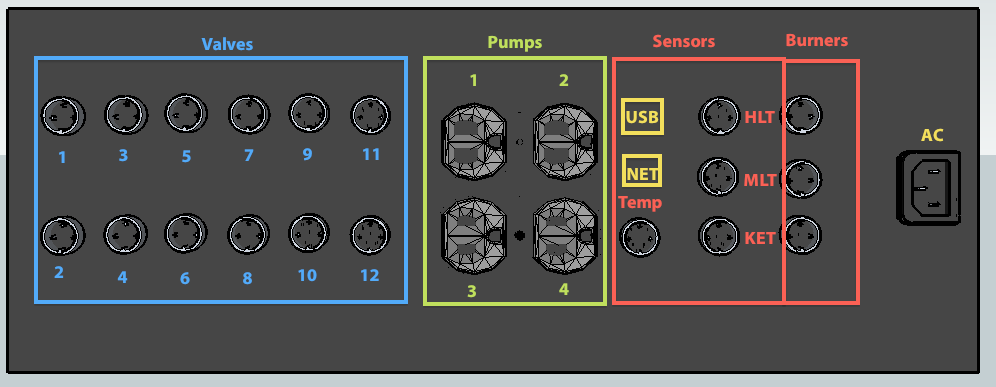

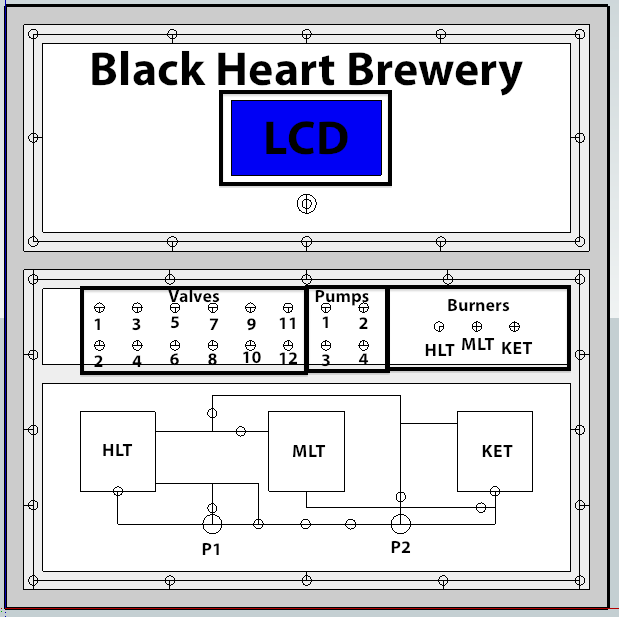

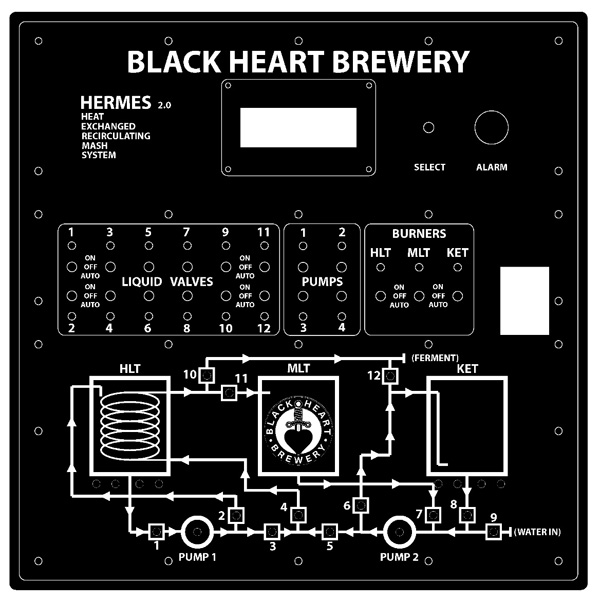

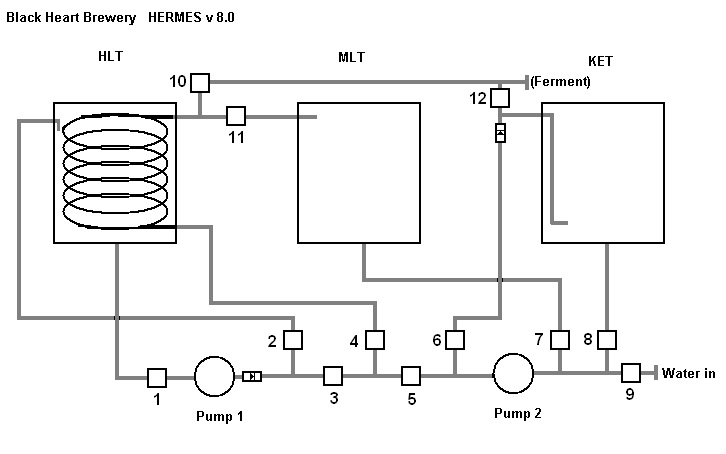

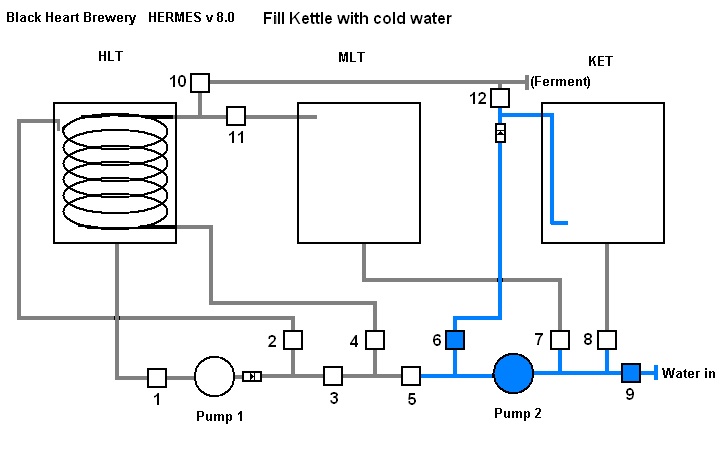

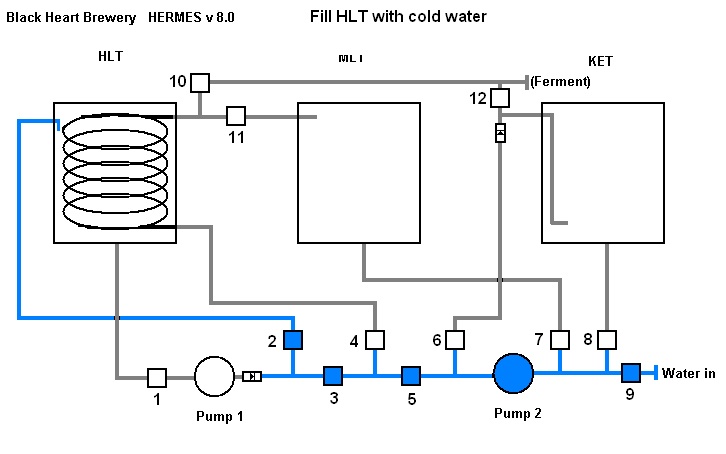

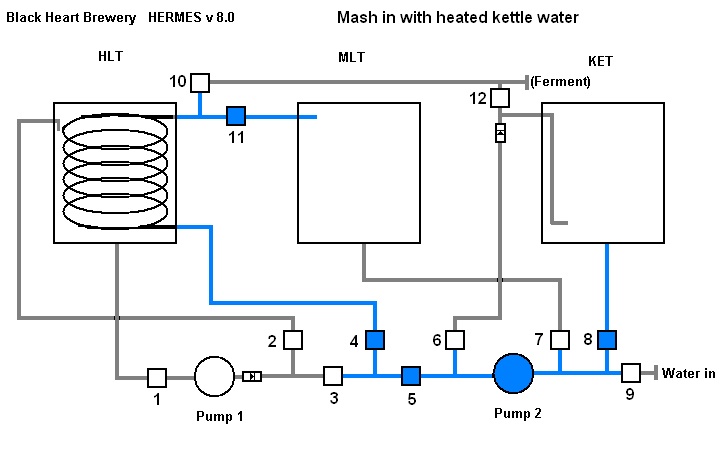

I think we have finally come up with a working design that addresses all of our current issues. We have 12x motorized ball valves, brew troller boards, and a number of other new parts to revamp the system. We are putting 9/12 of the valves under the brew system reducing the number of wires near the burners and the number of tubing runs we need.

Since we are fly sparging we have designed a system that will allow HLT -> MLT -> KET transfer at the same time, and also, recirculation of the MLT or KET while the water in the HLT is recirculating to maintain its own temp.

So I present you with a short animation of the proposed system to see what thoughts others might have before we go forward and start screwing things together.

( *note one way valves on pump 1 and KET input )

https://www.homebrewtalk.com/f11/automated-herms-system-132119/

We have hit a few snags with the system after brewing several batches on it. This is not a design flaw in the overall system but rather inadequate valves. The 12v solonid valves we are currently using do not totally seal, closed or open, leaving us with partially closed valves which messes with the pressure needed to get liquids from A -> B

Also, we have been experimenting with building our own automated controller. While this has been fun, in the same time we have been building the brew system, Brew Troller has created more mature and reliable product. The relay board alone is worth using thanks to the addition of built in LED and manual/auto switches.

So we decided its time to rebuild, better, more automated, more modular.

Our current system is fairly modular using TC fittings and silicon tubing. This means we have almost all the parts we need to reconfigure everything with a wrench and some teflon tape. Their were a few other minor things that were bothering us.

- No dedicated water input

- No dedicated output to a fermentor

- Lots of wires hanging from the top down towards the burners

The original goal of our brew system was to make a HERMS system that used the coil for both recirculation and cooling. We havent figured out a permanent water connection to the garage/brewery for the winter so we cant rely on a plate chiller etc to cool the beer year round. This has proven difficult to design as many inputs and outputs overlap.

I think we have finally come up with a working design that addresses all of our current issues. We have 12x motorized ball valves, brew troller boards, and a number of other new parts to revamp the system. We are putting 9/12 of the valves under the brew system reducing the number of wires near the burners and the number of tubing runs we need.

Since we are fly sparging we have designed a system that will allow HLT -> MLT -> KET transfer at the same time, and also, recirculation of the MLT or KET while the water in the HLT is recirculating to maintain its own temp.

So I present you with a short animation of the proposed system to see what thoughts others might have before we go forward and start screwing things together.

( *note one way valves on pump 1 and KET input )