BadWolfBrewing

Well-Known Member

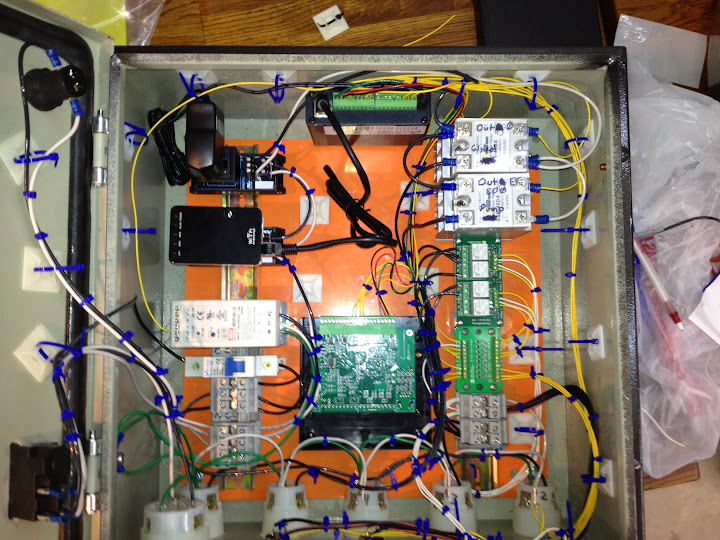

Can't wait to see finished product! It is amazing the different skills people have. For me, re-wiring the BCS would be the easy / fun part, but building the setup would be tricky, and look like **** when I was finished... as I prove every time I build something.

You get the ICs for the conicals yet? Will those be hard-plummed or TC'd in for easy removal and cleaning? I don't remember seeing, are you just using a cooler for the glycol reservoir?

You get the ICs for the conicals yet? Will those be hard-plummed or TC'd in for easy removal and cleaning? I don't remember seeing, are you just using a cooler for the glycol reservoir?