MikeRLynch

Well-Known Member

Ok, so here's the idea that I'm currently working on. Looking for input on ways to be more efficient. One caveat, this is for 3 gallon batches.

I live in a tiny apartment, so I'm constantly fighting the space issue. In short, I plan on mashing, boiling, AND fermenting in only two vessels. Batch sparge, no pumps, on an electric range. Here we go:

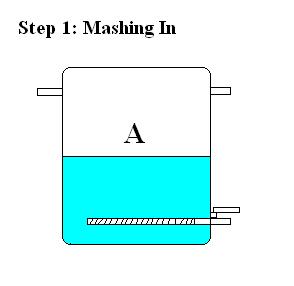

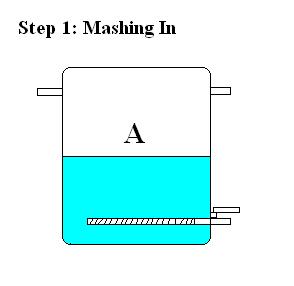

I will heat the mash water in a 5 gallon pot with a bazooka screen and ball valve. When I get up to dough in temps, I'll mix in the grain, put a lid on it, and stir till I'm down to mash temps. I will have a thermometer with an alarm on it to let me know when the temps decrease. If they do, I will put my burner on very low, and stir to bring the temp back up. If I need to, I'll leave the burner on to maintain mash temps.

I will then sparge out into my second vessel, another pot with a ball valve and a racking arm. I'll use my regular pasta pot to heat the sparge water up to 180 for the mash out.

Now here's the tricky part: When the mash is complete, I will dump the spent grains out of Pot A, clean it, and return it to the burner. The collected wort in Pot B will be dumped BACK into Pot A (stay with me, there's a reason). Boil will proceed as normal. The bazooka screen will act as a hop filter when running out. I will use a normal immersion wort chiller to cool.

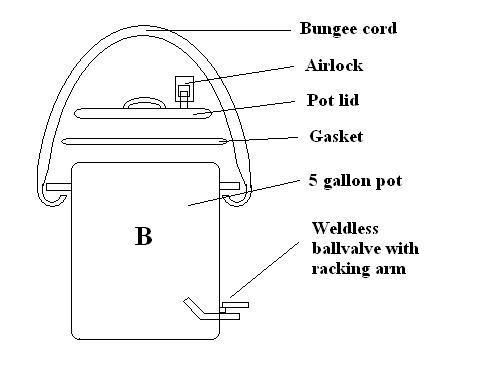

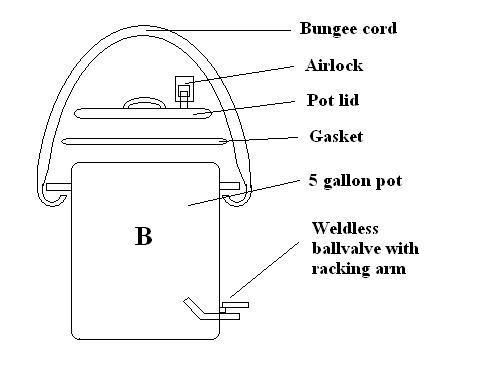

When the wort is cooled I will run it off BACK into Pot B, now converted into a fermentor and sanitized. The gasket will be cut from a large silicon baking sheet. I like the idea of fermenting in metal, and being able to rack through the ball valve.

Whew. Ok, what do you all think?

I live in a tiny apartment, so I'm constantly fighting the space issue. In short, I plan on mashing, boiling, AND fermenting in only two vessels. Batch sparge, no pumps, on an electric range. Here we go:

I will heat the mash water in a 5 gallon pot with a bazooka screen and ball valve. When I get up to dough in temps, I'll mix in the grain, put a lid on it, and stir till I'm down to mash temps. I will have a thermometer with an alarm on it to let me know when the temps decrease. If they do, I will put my burner on very low, and stir to bring the temp back up. If I need to, I'll leave the burner on to maintain mash temps.

I will then sparge out into my second vessel, another pot with a ball valve and a racking arm. I'll use my regular pasta pot to heat the sparge water up to 180 for the mash out.

Now here's the tricky part: When the mash is complete, I will dump the spent grains out of Pot A, clean it, and return it to the burner. The collected wort in Pot B will be dumped BACK into Pot A (stay with me, there's a reason). Boil will proceed as normal. The bazooka screen will act as a hop filter when running out. I will use a normal immersion wort chiller to cool.

When the wort is cooled I will run it off BACK into Pot B, now converted into a fermentor and sanitized. The gasket will be cut from a large silicon baking sheet. I like the idea of fermenting in metal, and being able to rack through the ball valve.

Whew. Ok, what do you all think?