Turtle Cook: The top shelf has the same cheap self adhesive vinyl floor tile surface although most of the time you can't see it. It is visible when I transport laying on its side.

bdvanza: I sometimes brew outdoors and sometimes late at night. The swivel mounted shop light has proved to be very useful. There's a power strip on the back side of the tower that the pump and shop light plug into. Not shown is the remote control I use for the the pump. The transmitter hangs on the inside back of the tower frame and plugs into the power strip. Note also the mini-shotgun replica igniter mounted to the side like a gun rack.

Tlhis hobby need not be totally serious all the time!

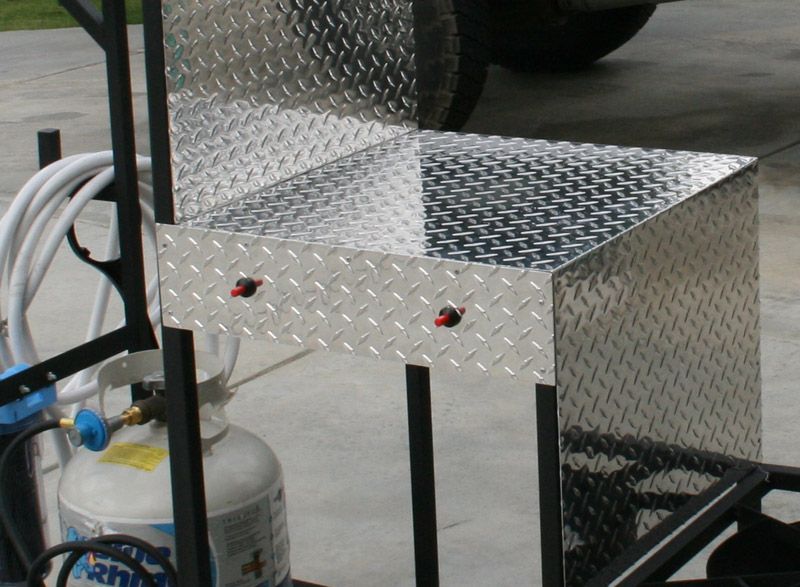

Space was the number one consideration for my set up and weight was number two. The tower foot print is only 2' x 2' and becasue its so light weight its easy to move around/transport.

the last one shows the water filter and my mash rake hanger.

bdvanza: I sometimes brew outdoors and sometimes late at night. The swivel mounted shop light has proved to be very useful. There's a power strip on the back side of the tower that the pump and shop light plug into. Not shown is the remote control I use for the the pump. The transmitter hangs on the inside back of the tower frame and plugs into the power strip. Note also the mini-shotgun replica igniter mounted to the side like a gun rack.

Tlhis hobby need not be totally serious all the time!

Space was the number one consideration for my set up and weight was number two. The tower foot print is only 2' x 2' and becasue its so light weight its easy to move around/transport.

the last one shows the water filter and my mash rake hanger.