dmcmillen

Well-Known Member

I'm looking for some suggestions for the best way to do a test mash with a small portion of the grain bill to determine pH. I see where some people use nested containers on the stove like a metal pan in a larger pot of warm/hot water. I am assuming:

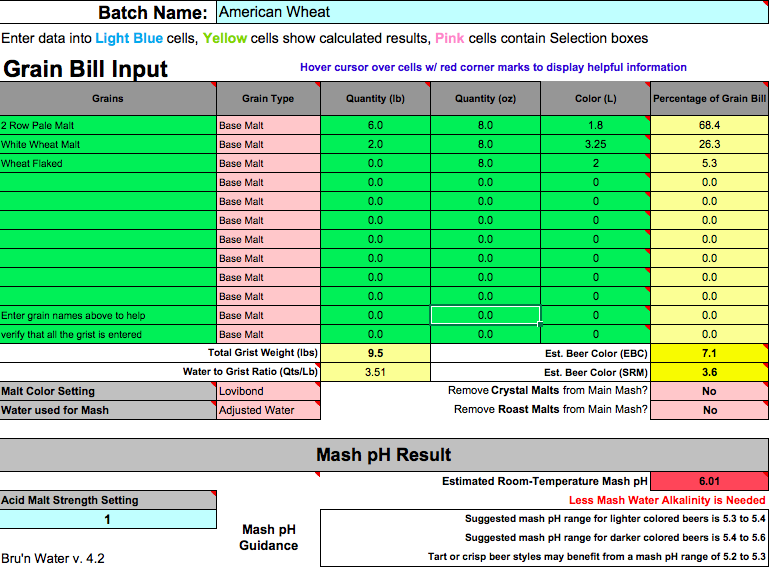

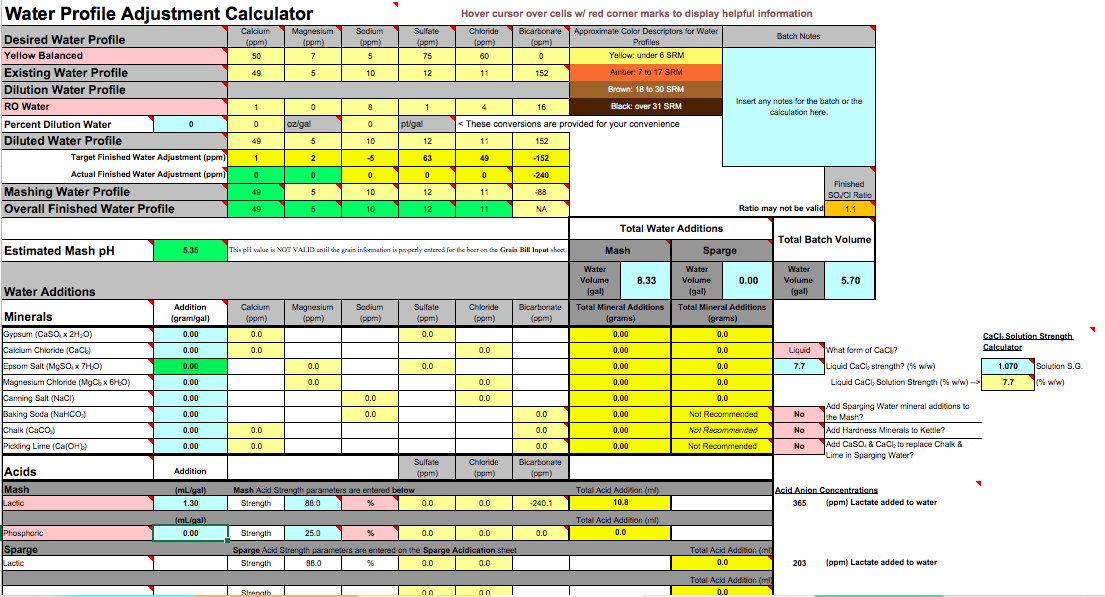

Scale down grain bill to about a pound of the base malt and reduce everything from there including water and water additions from Bru'n Waters' recommendations. Heat the treated mash water in one pan to strike, add grain, and set this pan in 2nd pan with warm/hot water to maintain mash temp. Take pH readings every 10 minutes to see where the pH finally levels out (probably around 30 - 45 mins ,assuming a 60 min mash). Make acid/base adjustments as necessary to reach target pH, I guess scaling down from what it would take to vary pH by .1 in Bru'N Waters' recommendations for the full sized batch. I would add about 1/2 of that, stir well, wait a couple of minutes and test again, then add the rest, if necessary. Have I got this right?

I read that some folks only make adjustments if pH is outside the 5.2 - 5.6 range. Thoughts here?

From here do I just scale up the additions I made to get to desired pH to full batch, sticking with the original Bru'N Water batch treatments changing only the adjustment additions? Or do I do something to change my Bru'N Water inputs?

BTW, I have a Milwaukee 102 and would calibrate it before starting.

Scale down grain bill to about a pound of the base malt and reduce everything from there including water and water additions from Bru'n Waters' recommendations. Heat the treated mash water in one pan to strike, add grain, and set this pan in 2nd pan with warm/hot water to maintain mash temp. Take pH readings every 10 minutes to see where the pH finally levels out (probably around 30 - 45 mins ,assuming a 60 min mash). Make acid/base adjustments as necessary to reach target pH, I guess scaling down from what it would take to vary pH by .1 in Bru'N Waters' recommendations for the full sized batch. I would add about 1/2 of that, stir well, wait a couple of minutes and test again, then add the rest, if necessary. Have I got this right?

I read that some folks only make adjustments if pH is outside the 5.2 - 5.6 range. Thoughts here?

From here do I just scale up the additions I made to get to desired pH to full batch, sticking with the original Bru'N Water batch treatments changing only the adjustment additions? Or do I do something to change my Bru'N Water inputs?

BTW, I have a Milwaukee 102 and would calibrate it before starting.