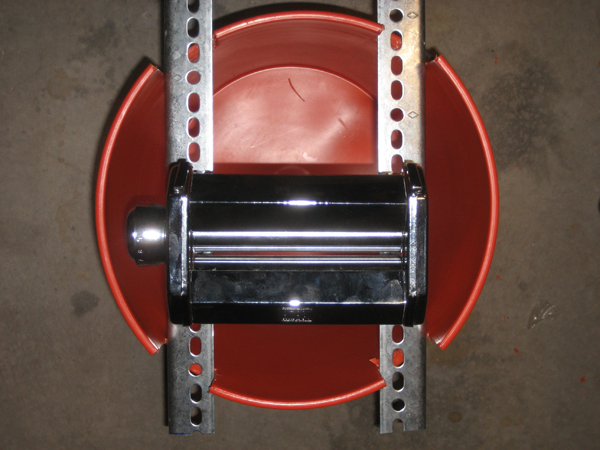

I struggled for a long time to roughen the rollers enough to pull the grain through at an even pace. What really made a huge difference was conditioning the grain before hand with a spray bottle till it was the texture of damp leather. I read about the procedure here...

http://www.braukaiser.com/wiki/index.php?title=Malt_Conditioning

Previously I was getting too much flour and stuck sparges with my roller settings. After conditioning, the same settings gave me a beautiful crush at a reasonable pace.

http://www.braukaiser.com/wiki/index.php?title=Malt_Conditioning

Previously I was getting too much flour and stuck sparges with my roller settings. After conditioning, the same settings gave me a beautiful crush at a reasonable pace.