Brewpastor

Beer, not rocket chemistry

For many years I have used a slotted copper false bottom on my MLT. It really has been fine, and made some wonderful beers, but I am always in search of a new project. So I decided to build a deluxe, stainless braid false bottom (SFB). I blame this all on Dude because he sent me some wonderful brews. I first had his Pliny the Bastard and thought "why not make a new SFB?" Then I drank his Red Eye Rye and thought, "Why not make it a double?"

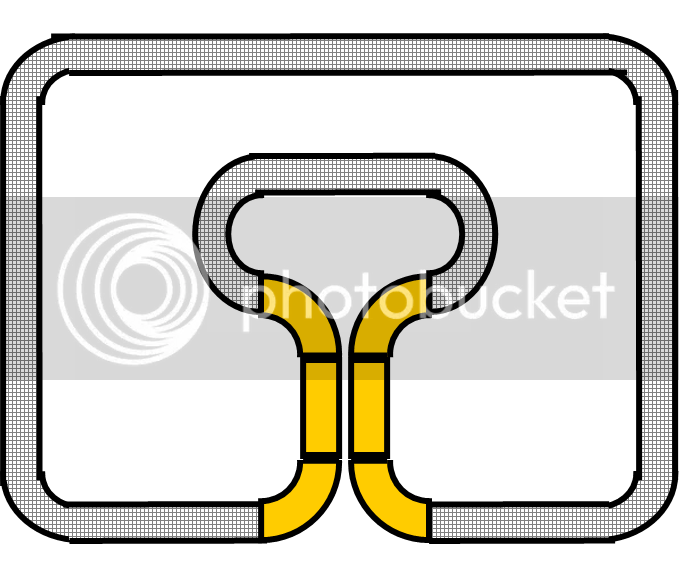

So I got busy with my saw, torch, copper and stainless and came up with this:

As you can see, it is a double looped SFB. In the process I came up with an idea that I utilized. I don't know if others have thought of this or not, but WTH, I did. The stainless braid is very flexible and tends to want to stretch out. So I ran a length of 18 gauge copper wire through the lenght of braid and secured it on each end with my clamps, creating a limit or brake to the expansion. Clever idea, if I don't say so myself.

Installed in my MLT the SFB looks like this:

So that is my gift to the Home Brew Gawds this day. I did not brew the 777 and will use that brew next week as a test of my new SFB. But I thought some of you might like the idea and appreciate the effort. But don't thank me, thank Dude. This project was 100% Dude's brew powered. :rockin:

So I got busy with my saw, torch, copper and stainless and came up with this:

As you can see, it is a double looped SFB. In the process I came up with an idea that I utilized. I don't know if others have thought of this or not, but WTH, I did. The stainless braid is very flexible and tends to want to stretch out. So I ran a length of 18 gauge copper wire through the lenght of braid and secured it on each end with my clamps, creating a limit or brake to the expansion. Clever idea, if I don't say so myself.

Installed in my MLT the SFB looks like this:

So that is my gift to the Home Brew Gawds this day. I did not brew the 777 and will use that brew next week as a test of my new SFB. But I thought some of you might like the idea and appreciate the effort. But don't thank me, thank Dude. This project was 100% Dude's brew powered. :rockin: